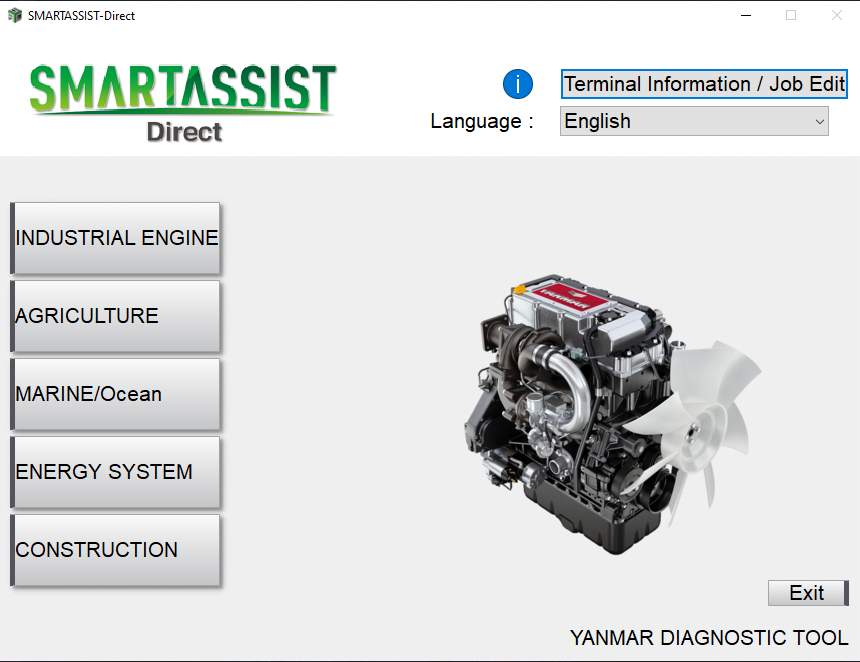

YANMAR DIAGNOSTIC TOOL SA-DIRECT 2.45.0: Optimize Your Heavy Machinery Diagnostics

The YANMAR DIAGNOSTIC TOOL SA-DIRECT 2.45.0 is a vital software solution for maintaining Yanmar’s heavy machinery and trucks. It offers advanced diagnostic capabilities, ensuring optimal performance and reliability for various models. This tool supports a range of essential features, including real-time data collection and error detection. Additionally, the installation process is streamlined through TeamViewer, making setup straightforward for users.

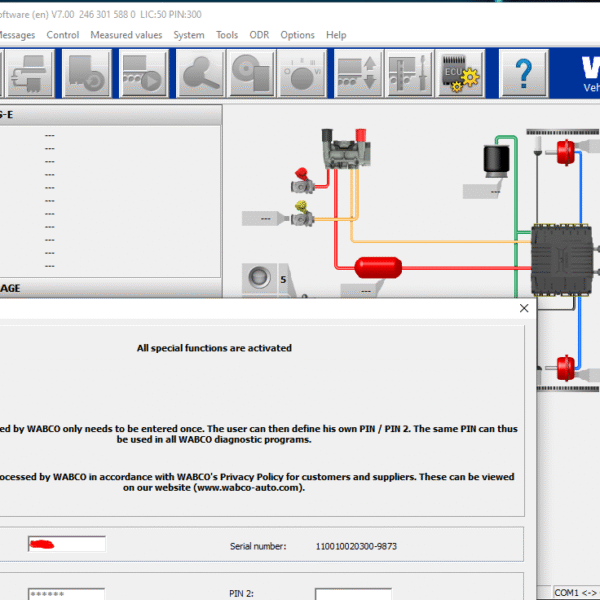

Overview of Yanmar Diagnostic Tool SA-Direct 2.45.0

This software solution plays a crucial role in enhancing the performance and reliability of Yanmar machinery.

Importance in Heavy Machinery Maintenance

Regular maintenance is vital for the longevity and efficiency of heavy machinery. The Yanmar Diagnostic Tool facilitates effective maintenance practices by providing precise diagnostic capabilities. With access to real-time data and error detection, technicians can identify and address potential issues before they escalate into costly repairs. This proactive approach contributes significantly to minimizing downtime and ensuring smooth operations.

Compatibility with Yanmar Products

This tool is designed to integrate seamlessly with a wide range of Yanmar products. Its compatibility extends across various models, including:

- Excavators

- Marine engines

- Tractors

- Generations of agricultural machinery

Such versatility ensures that users can utilize the diagnostic tool across their existing fleet, enhancing its value and utility in various operational environments.

Key Features of the Software

Numerous features define the Yanmar Diagnostic Tool, making it an indispensable asset for technicians:

- Multilingual Support: The software supports multiple languages, enhancing accessibility for users worldwide.

- Error Diagnosis: It detects and diagnoses errors with efficiency.

- Real-Time Data Tracking: Users can monitor engine performance in real time.

- Reprogramming Capabilities: Allows for adjustments to optimize performance.

These functionalities are integral in ensuring consistent maintenance and operational excellence.

Installation Process

Installing the Yanmar Diagnostic Tool SA Direct 2.45.0 involves a clear and defined process. The following sections outline the necessary system requirements and provide an easy-to-follow guide for installation via TeamViewer.

System Requirements

Before beginning the installation, it’s crucial to ensure that the computer meets the following specifications:

- Operating System: Windows 10 (64-bit) or Windows 11 (64-bit).

- Available Storage: Approximately 387 MB of free disk space is needed.

- Internet Connection: An internet connection is necessary for downloading updates and additional modules.

Step-by-Step Installation via TeamViewer

The installation procedure is straightforward when using TeamViewer. Below are the steps to follow:

Downloading the Software

Upon purchasing the software, a download link will be provided. Ensure that this link is accessed through a supported system for optimal results.

Setting Up the Interface

After downloading, run the installer and follow these steps:

- Double-click on the downloaded file to initiate the installation.

- Follow the on-screen prompts to configure initial settings, including language selection.

- Enter the license key provided during purchase to activate the software.

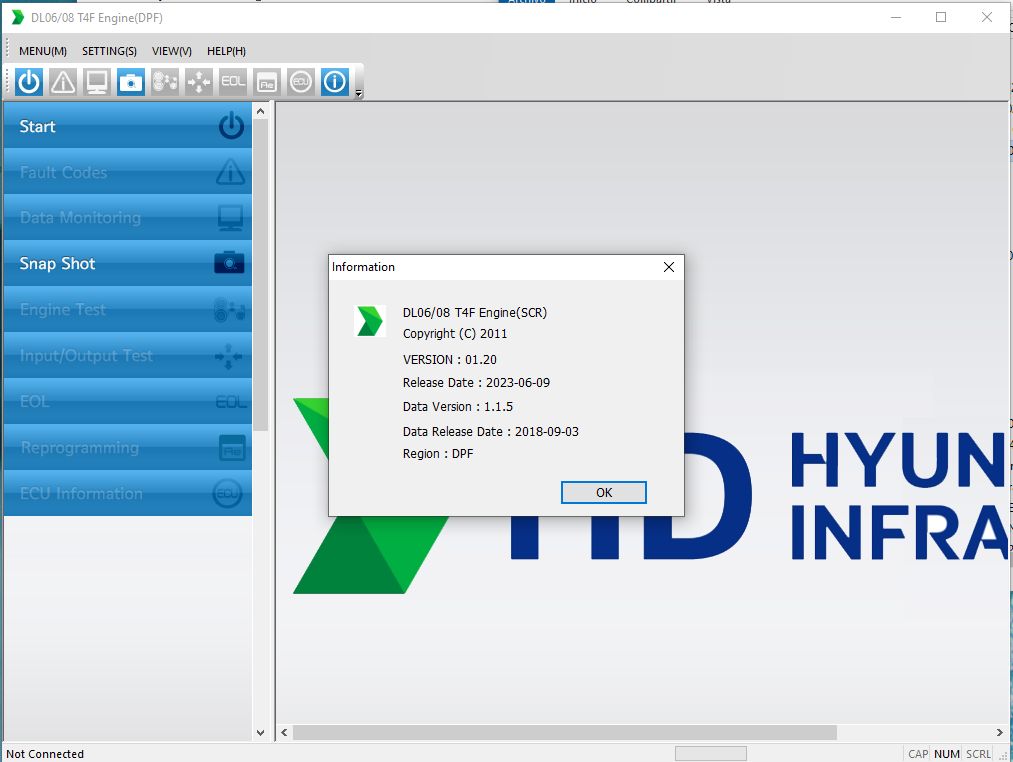

Diagnostic Capabilities

The diagnostic capabilities of the software are designed to enhance troubleshooting efficiency and machine performance. With advanced features, the tool empowers technicians to quickly identify issues, ensuring optimal operation.

Error Detection and Troubleshooting

Robust error detection is a cornerstone of this software, facilitating swift issue identification. The key aspects include:

- Reading error codes to pinpoint specific problems in Yanmar engines and machinery.

- Providing detailed descriptions and possible solutions for each error detected.

- Allowing technicians to clear error codes after addressing the underlying issues, which aids in maintaining machine integrity.

Real-Time Data Collection

This software supports extensive data collection during operation. Key features include:

- Gathering performance metrics in real-time, which helps in monitoring engine health.

- Tracking operational parameters to discover trends over time and predict potential failures.

- Enabling informed decisions based on current performance and historical data patterns.

Visual Data Representation

Visual data representation enhances the clarity of information provided by the software. Important elements involve:

- Graphical displays of real-time data that simplify complex information analysis.

- Charts and graphs that illustrate engine performance over time, aiding in performance assessments.

- Clear visualization of diagnostic results, making it easier for technicians to interpret data and take necessary actions.

Maintenance Functions

The maintenance functions offered by the software are vital for prolonging the lifespan and efficiency of Yanmar machinery. These functions facilitate both preventive measures and performance assessments to ensure optimal operation.

Preventive Maintenance Features

Preventive maintenance plays a crucial role in minimizing machine downtime and avoiding costly repairs. This software provides a suite of features designed to help operators implement effective maintenance strategies, including:

- Regular performance evaluations to identify potential issues early.

- Setting up maintenance schedules based on operating hours or specific criteria.

- Alerts for routine checks and necessary interventions before problems escalate.

Performance Monitoring and Alerts

The ability to monitor performance in real-time is a key advantage of the software. This section allows users to track critical engine parameters continuously. Key aspects include:

- Gathering and displaying data on engine efficiency and operational metrics.

- Configurable alerts to notify users of any anomalies or deviations from set performance standards.

These monitoring capabilities enhance operational readiness and reduce the risk of unexpected failures.

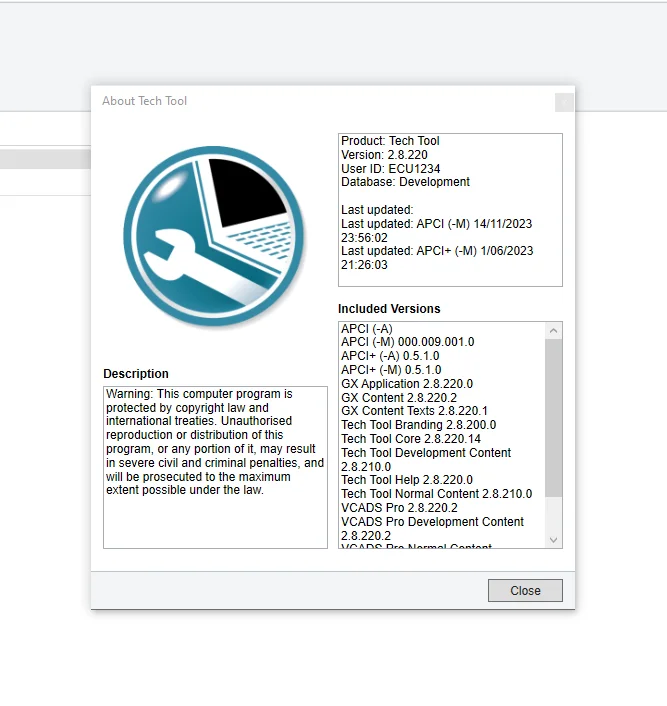

Reprogramming and Updates

This section covers the essential aspects of reprogramming engine parameters and the process of installing software updates within the Yanmar Diagnostic Tool.

Adjusting Engine Parameters

Engine parameters can significantly influence performance and efficiency. With the Yanmar Diagnostic Tool, users can adjust these settings to meet specific operational needs. This includes tuning fuel injection rates, adjusting throttle response, and optimizing idle conditions. Such modifications aim to enhance functionality and responsiveness, ensuring machinery operates at its peak.

Installing Software Updates

Keeping software up to date is crucial for optimizing the performance of diagnostic tools. Regular updates introduce critical improvements and new features. The installation process is carried out seamlessly through the following steps:

- Access the update section within the software interface.

- Check for available updates by connecting to the internet.

- Download the latest software version directly from the platform.

- Follow on-screen instructions to install the updates.

Staying current with software updates can lead to improved diagnostics and troubleshooting capabilities, further aiding technicians in their maintenance efforts.

Model Compatibility

Understanding the compatibility of the Yanmar Diagnostic Tool is crucial for ensuring effective diagnostics across various machinery.

Construction Machines and Trucks

This diagnostic tool is designed to work seamlessly with a wide array of construction machines and trucks. Machinery users can expect comprehensive support for various models, enhancing overall maintenance efficiency.

- Excavators

- Bulldozers

- Dump trucks

- Backhoe loaders

The tool’s compatibility extends to both older and newer models, making it a versatile choice for different operational needs.

Specific Yanmar Series Supported

Several specific Yanmar series benefit from the diagnostic capabilities. Compatibility across multiple series allows for tailored solutions based on machinery type.

- ViO Series: Especially models such as ViO30-6, ViO45-6, and ViO55-6

- YT Series: Includes multiple tractor models with diverse applications

- EG Series: Renowned for robust performance in various conditions

This broad support is essential for owners of Yanmar products, enabling improved maintenance and operational reliability.

Benefits of Using Yanmar Diagnostic Tool SA Direct

The advantages of utilizing this diagnostic tool are significant, offering both efficiency and accessibility for users in various industries.

Cost and Time Efficiency

Implementing this software leads to considerable savings in both time and money. Key factors contributing to these benefits include:

- Rapid diagnosis of issues minimizes downtime for heavy machinery.

- Proactive maintenance capabilities allow for early detection of potential problems.

- Streamlined troubleshooting reduces the need for extensive manual checks.

These efficiencies can greatly impact the operational costs, leading to a more effective allocation of resources.

Global Accessibility Through Multilingual Support

The software’s design caters to a diverse user base by offering multilingual support. This feature facilitates ease of use worldwide, providing:

- Translation options in major languages, such as English, Japanese, Chinese, and Korean.

- Increased usability for technicians in various geographical locations, enhancing communication and understanding.

- Support for international operations, ensuring consistent performance across different markets.

Such accessibility ensures that users can efficiently navigate and utilize the tool, enhancing their overall experience.

Frequently Asked Questions

This section addresses common inquiries related to the Yanmar Diagnostic Tool, focusing on troubleshooting and support.

Troubleshooting Common Issues

Users may encounter various issues while using the diagnostic tool. Here are some frequent problems and their solutions:

- Installation Errors: If the software fails to install, ensure that all system requirements are met and that the correct version is being used.

- Connection Problems: For issues connecting to equipment, verify that the communication cables are secure and undamaged.

- Error Codes: If specific error codes appear, consult the user manual for guidance on what these codes signify and how to resolve them.

Contacting Support for Assistance

For further help, reaching out to customer support is recommended. Here are some options available:

- Online Resources: Check the official Yanmar website for FAQs, troubleshooting articles, and user forums.

- Technical Support: Utilize available technical support channels for detailed assistance and personalized solutions.

- Software Updates: Ensure that the latest software version is being used, as updates often fix known issues and enhance functionality.

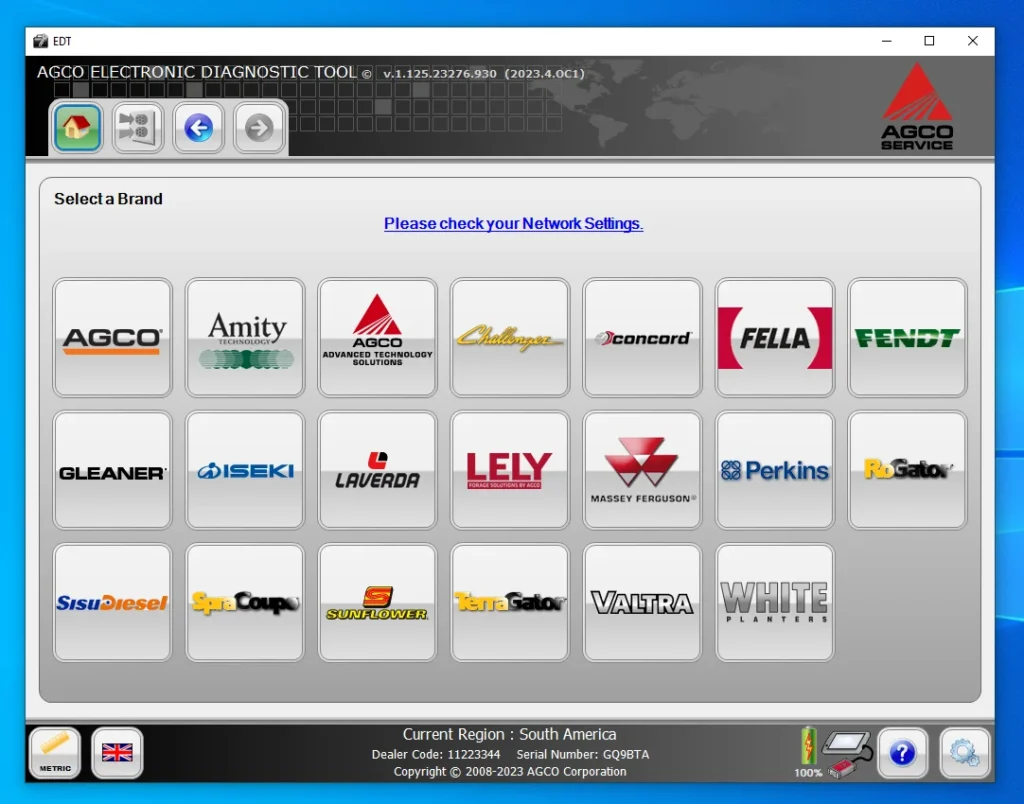

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.