Circuit Description

The crankshaft position and camshaft position sensors are Hall effect type sensors. The engine control module (ECM) provides a 5 volt supply to the position sensor and a return circuit. As the teeth on the crankshaft speed ring or the dimples in the back of the camshaft gear move past the position sensor, a signal is generated on the position sensor signal circuit. The ECM interprets this signal and converts it to an engine speed. A missing tooth on the crankshaft gear is used by the ECM to determine the position of the engine.

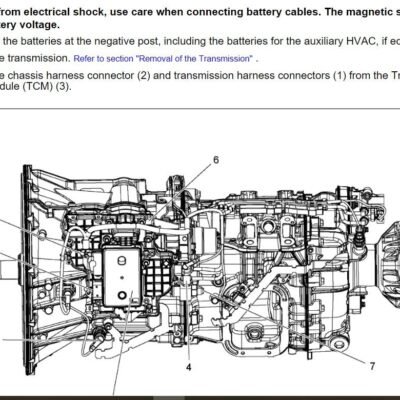

Component Location

The crankshaft position and camshaft position sensor location varies, depending on engine model.

Conditions for Running the Diagnostics

This diagnostic runs continuously when the engine is running and during cranking.

Conditions for Setting the Fault Codes

The Engine Control Module (ECM) detected a loss of both engine speed/position signals.

Action Taken When the Fault Code is Active

For On-Board Diagnostics (OBD) engines, the ECM illuminates the Malfunction Indicator Lamp (MIL) immediately when the diagnostic runs and fails.

The engine may not start.

Conditions for Clearing the Fault Code

To validate the repair, perform a key cycle, start the engine and let it idle for 1 minute.

The fault code status displayed by INSITE™ electronic service tool will change to INACTIVE immediately after the diagnostic runs and passes.

For On-Board Diagnostics (OBD) engines, the ECM will extinguish the Malfunction Indicator Lamp (MIL) after three consecutive trips where the diagnostic runs and passes.

The Reset All Faults command in INSITE™ electronic service tool can be used to clear active and inactive faults, as well as extinguish the MIL for OBD applications.

Shop Talk

This fault code indicates the crankshaft position sensor and the camshaft position sensor have lost synchronization or the wiring harness connectors are reversed.

Possible Cause:

1) Battery failure

2) ECM calibration

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

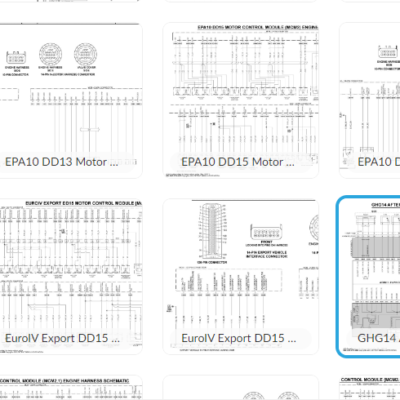

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

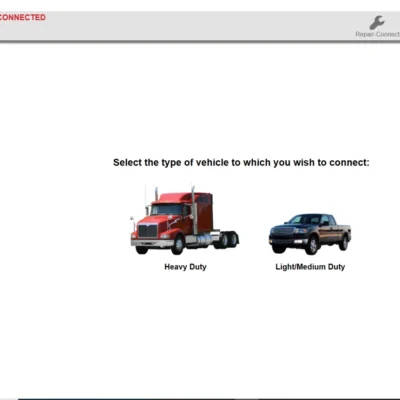

![DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06] is a vital diagnostic software designed for heavy machinery. It provides users with tools for efficient maintenance and monitoring of DOOSAN trucks and equipment. This software simplifies problem identification and performance tracking. It also offers support for remote installations using TeamViewer, making it accessible and user-friendly for operators and technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/44-1-400x400.png)

Reviews

Clear filtersThere are no reviews yet.