Circuit Description

The ether injection circuit is a device used by the engine to control the ether injection operation. The ether injection circuit utilizes a Pulse Width Modulated (PWM) signal. A PWM signal is pulsed voltage signal between 0-VDC and system voltage. The frequency of the pulsed voltage signal is dependent on the application requirement.

Component Location

The control solenoid location varies by OEM. Refer to the appropriate OEM service manual to determine the location.

Conditions for Running the Diagnostics

This diagnostic runs when the keyswitch is in the ON position and when the pulse width modulated (PWM) device is getting energized or de-energized. In some cases, the diagnostics can also run at some fixed intervals.

Conditions for Setting the Fault Codes

The ether injection circuit pulse width modulated (PWM) signal detected a voltage greater than 0-VDC when the PWM signal was turned off by the ECM.

Action Taken When the Fault Code is Active

The ECM illuminates the amber CHECK ENGINE lamp immediately when the diagnostic runs and fails.

The ether injection operation will be disabled.

Conditions for Clearing the Fault Code

To validate the repair, perform a key cycle, and leave the key in the ON position for 1 minute.

The fault code status displayed by INSITE™ electronic service tool will change to INACTIVE immediately after the diagnostic runs and passes.

The ECM will turn off the amber CHECK ENGINE lamp immediately after the diagnostic runs and passes.

The Reset All Faults command in INSITE™ electronic service tool can be used to clear active and inactive faults, as well as extinguish the MIL for OBD applications.

Shop Talk

Possible causes of this fault include:

An open circuit in the engine harness or ether injection solenoid

A short circuit to voltage source in the OEM harness

A malfunctioning ECM.

Possible Cause:

1) Ether injection solenoid failure

2) OEM harness

3) ECM failure

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

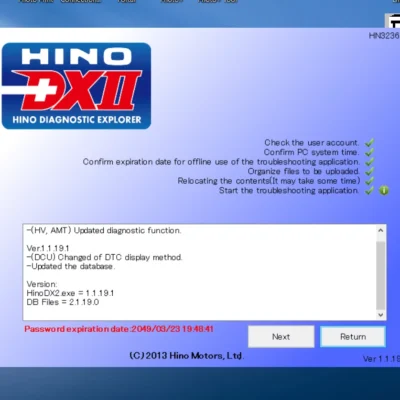

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The Hitachi Construction Machinery MPDr Ver 3.7.0.0 [10.2020] Diagnostic Software optimizes operations in heavy construction machinery. With advanced diagnostics, seamless integration with Hitachi equipment, and a focus on efficiency and productivity, it enhances performance in the industry. Trust the reliability of Hitachi Construction Machinery for this powerful software solution. Learn more about its features, benefits, and how it can benefit your operations at ecmtrucks.com. Increase efficiency with Hitachi Construction Machinery MPDr Ver 3 7 0 0.](https://ecmtrucks.com/wp-content/uploads/2024/01/MPDR-3.7.00-400x400.webp)

Reviews

Clear filtersThere are no reviews yet.