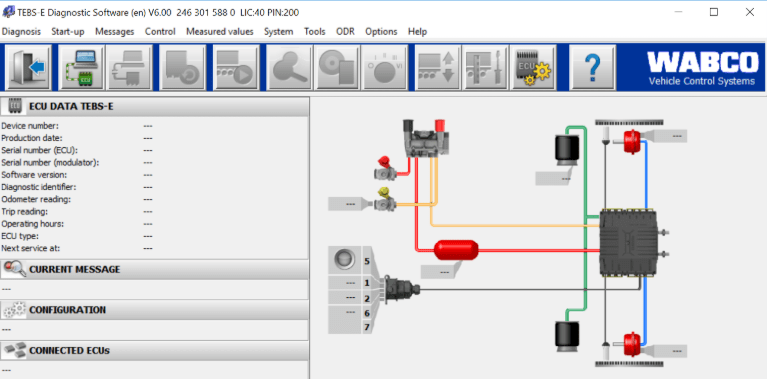

WABCO TEBS-E 7.0 2025: Advanced Diagnostic Software for Trucks

WABCO TEBS-E 7.0 2025 is a cutting-edge diagnostic program designed for heavy machinery and trucks. It provides essential monitoring and error detection capabilities, enhancing overall fleet efficiency. The software plays a crucial role in identifying issues quickly, allowing for timely maintenance and reducing downtime. Its user-friendly installation process can be done remotely via TeamViewer, ensuring convenience and accessibility for users.

Understanding WABCO TEBS-E 7.0 2025

This section provides insights into the WABCO TEBS-E 7.0 2025, shedding light on its technology, features, and significance within the heavy machinery industry.

Overview of WABCO Technology

WABCO has established itself as a leader in braking and stability control systems for commercial vehicles. The TEBS (Trailer Electronically Braked System) E 7.0 2025 is a testament to their commitment to enhancing safety and efficiency on the road. Utilizing advanced technology, it serves as an integral component for managing braking systems in heavy-duty trucks and trailers.

The integration of electronic control units allows for precise modulation of braking forces, thereby increasing safety and responsiveness during operation. With innovations aimed at reducing wear and tear, WABCO technology ensures optimized vehicle performance and longevity.

Key Features of TEBS-E 7.0 2025

The TEBS-E 7.0 2025 comes equipped with numerous features designed to enhance operational efficiency and improve safety standards. These features include:

- Diagnostic Capabilities: Advanced diagnostic tools enable real-time monitoring and quick identification of potential issues.

- Enhanced Stability: The system supports vehicle stability during braking, especially under challenging conditions.

- Automatic Adjustments: Automatic leveling and adjustments ensure optimal braking performance at all times.

- Efficient Energy Management: The system optimizes energy use for braking, contributing to lower operational costs.

Such features make the TEBS-E 7.0 2025 not only user-friendly but also a cost-effective solution for fleet operators.

Importance in Heavy Machinery

Within the heavy machinery sector, the WABCO TEBS-E 7.0 2025 plays a crucial role in promoting safety and reliability. As regulatory pressures increase, the need for robust braking systems becomes even more vital. This technology addresses these concerns by ensuring compliance with safety regulations and standards.

Furthermore, its application extends beyond simply enhancing safety. By improving braking efficiency and reliability, it contributes significantly to fleet management strategies. Fleet operators benefit from reduced downtime and maintenance costs, leading to improved profitability.

The TEBS-E 7.0 2025 ultimately exemplifies how innovative technology can drive advancements in the heavy machinery industry, fostering safer and more sustainable operations.

Installation Process

The installation process of WABCO TEBS-E 7.0 2025 is critical to ensuring optimal functionality. This section outlines the necessary steps for setting up the software and addresses potential issues that may arise during installation.

Preparing for Installation

Before beginning the installation, several preliminary steps must be taken. Proper preparation ensures a smooth installation process. Key considerations include:

- Check system requirements: Verify that the hardware and software meet the minimum specifications required for the WABCO TEBS-E 7.0 2025 software.

- Gather necessary tools: Ensure that you have the necessary tools, including a computer with a stable internet connection and the TeamViewer application if remote installation is needed.

- Backup existing data: It is advisable to backup any existing data on the device to prevent data loss during the installation process.

Step-by-Step Installation Guide

The installation process can be executed in a few straightforward steps. Follow this guide to ensure proper setup:

- Download the software: Access the official site or a trusted source to download the WABCO TEBS-E 7.0 2025 software.

- Run the installer: Locate the downloaded file and double-click to initiate the installation wizard.

- Follow on-screen instructions: Carefully adhere to the prompts provided by the installation wizard. This includes accepting the license agreement and selecting the installation directory.

- Complete the installation: Once the installation wizard has finished, restart your computer if prompted.

- Launch the software: Open the WABCO TEBS-E 7.0 2025 software to confirm that the installation was successful.

Troubleshooting Common Installation Issues

Even with careful preparation and adherence to the installation steps, issues may still arise. Recognizing and addressing these problems is crucial for successful installation.

Connection Problems

If experiencing issues related to connection during installation, consider the following:

- Check internet connectivity: Ensure that the device has a stable internet connection for downloading software and accessing online resources.

- Firewalls and antivirus settings: Adjust settings to allow the installer and TeamViewer to communicate without being blocked.

- Router settings: Sometimes, router configurations may restrict connections. Check settings and restart the router if necessary.

Compatibility Issues

Compatibility problems can impede the installation process. If faced with these issues, review the following:

- Operating system: Verify that the operating system is supported by the WABCO TEBS-E 7.0 2025 software.

- Hardware requirements: Ensure that the hardware specifications align with the requirements listed in the software documentation.

- Previous versions: If an older version of the software is already installed, it may interfere with the new installation. Uninstall any previous versions prior to commencing installation.

Diagnostic Capabilities

The diagnostic capabilities of WABCO TEBS-E 7.0 2025 provide critical insights into the operational status of heavy machinery and trucks. These features facilitate real-time monitoring and efficient error management, ultimately leading to enhanced performance and reliability.

Real-Time Monitoring

This system offers continuous tracking of various parameters, allowing operators to gain immediate access to the health and performance data of their vehicles. By monitoring key metrics, potential issues can be detected before they escalate into serious problems.

Key elements of real-time monitoring include:

- Vehicle speed and braking performance

- Temperature readings for critical components

- Fuel consumption efficiency

- Battery voltage levels

Such comprehensive monitoring capabilities enhance decision-making processes for fleet management, ensuring that maintenance can be performed proactively rather than reactively.

Error Detection and Reporting

Efficient error detection is another crucial aspect of the WABCO TEBS-E 7.0 2025. This feature quickly identifies malfunctions and provides structured reporting that aids in resolving issues effectively.

Specific advantages of the error detection system include:

- Rapid identification of faults

- Detailed error logs for historical analysis

- Systematic fault isolation to minimize downtime

Common Error Codes

The system generates a list of common error codes that can be easily interpreted by technicians. These codes are essential for diagnosing specific issues and can drastically reduce repair times by directing attention to the root cause of a problem.

Examples of frequently encountered error codes might include:

- Brake system malfunctions

- Engine performance warnings

- Electrical system errors

Automatic Alerts

Automatic alerts enhance the responsiveness of the system to potential issues. Notifications can be set to trigger when certain thresholds are crossed, allowing fleet managers and operators to take timely action.

These alerts serve various functions, including:

- Immediate warning during critical failures

- Periodic updates about vehicle condition

- Scheduled maintenance reminders based on performance data

Using TeamViewer for Installation

Remote installation using TeamViewer provides an efficient method to set up software like the WABCO TEBS-E 7.0 2025. This approach streamlines the process and reduces the time needed for installation, ensuring users can quickly access the diagnostic features of their machinery.

Benefits of Remote Installation

Utilizing TeamViewer comes with several advantages for users.

- Convenience: Installation can be completed from any location, eliminating the need for physical presence at the machine site.

- Time-Saving: Remote access allows for quicker installations compared to traditional methods.

- Expert Assistance: Users can receive real-time support from technical experts, enhancing the installation experience.

- Cost-Effective: Reducing travel expenses for technicians contributes to overall savings.

Step-by-Step Guide to Using TeamViewer

Following a systematic approach ensures successful installation through TeamViewer.

- Step 1: Install TeamViewer on the computer where the diagnostic software will be set up.

- Step 2: Launch TeamViewer and share the access ID and password with the technician.

- Step 3: The technician connects to the user’s machine remotely using the provided credentials.

- Step 4: Once connected, the technician initiates the software installation process.

- Step 5: After installation is complete, verify the setup by running diagnostic checks.

Ensuring Secure Connections

Maintaining security during remote installations is crucial for protecting sensitive data.

- Use Unique ID and Password: Ensure that the TeamViewer session is initiated with a unique ID and password generated for each session.

- Enable Two-Factor Authentication: Activate this feature in TeamViewer settings to add an extra layer of security.

- Monitor Active Connections: Regularly check for active sessions and disconnect any unauthorized access immediately.

- Use Trusted Networks: Perform remote installations on secure and trusted internet connections to minimize risks.

Enhancing Fleet Management

Effective fleet management is crucial for maximizing operational efficiency and minimizing costs. The integration of advanced diagnostic tools provides vital data that can significantly enhance fleet operations and decision-making processes.

Integration with Fleet Management Software

Seamless integration with existing fleet management software is essential for optimizing performance. By incorporating diagnostic programs, operators can centralize information, allowing for improved oversight. This connectivity ensures that all relevant data is easily accessible and actionable.

- Facilitates real-time tracking of vehicle conditions.

- Improves communication between team members and management.

- Enables better resource allocation based on performance data.

Data Analysis for Improved Efficiency

Collecting data from heavy machinery and trucks is only the beginning. Effective data analysis helps in identifying trends and pinpointing inefficiencies within the fleet.

- Fuel consumption metrics provide insights for cost-saving strategies.

- Maintenance schedules based on actual usage data reduce unnecessary downtime.

- Performance reports highlight areas for improvement, ensuring the fleet operates at peak efficiency.

Predictive Maintenance Benefits

Utilizing predictive maintenance strategies significantly enhances fleet reliability. This approach is grounded in data-driven insights that anticipate potential failures before they occur. By leveraging these advanced tools, companies can stay ahead of mechanical issues.

Reducing Downtime

Minimizing equipment downtime is critical for maintaining productivity. Predictive maintenance allows for scheduling repairs during non-peak times, thus reducing the impact on operations. Advanced diagnostic systems help spots warning signs early on, preventing unexpected breakdowns that can disrupt services.

Extending Equipment Lifespan

Regular monitoring and timely intervention can dramatically extend the lifespan of vehicles and machinery. By addressing wear and tear before it escalates, fleets can maximize their investments. This proactive approach safeguards against costly replacements and maintains operational continuity.

Frequently Asked Questions

This section addresses common inquiries related to WABCO TEBS-E 7.0 2025. It covers pricing, compatibility, and support options to enhance user understanding and facilitate the purchase decision.

Pricing and Availability

The pricing for WABCO TEBS-E 7.0 2025 varies based on the vendor and specific licensing options selected. Users can typically expect competitive rates for this advanced diagnostic software.

Availability is generally high, with multiple distributors offering the product. It is advisable to check with authorized dealers for the most accurate purchase options and stock status.

Compatibility with Other Systems

WABCO TEBS-E 7.0 2025 is designed to integrate seamlessly with various heavy machinery and truck systems. Users should verify compatibility with their existing fleet management software to ensure optimal performance.

The software supports multiple vehicle models and systems. Reviewing the technical specifications provided by WABCO can help determine if the product meets specific needs.

Technical Support Channels

A range of technical support options is available for users of WABCO TEBS-E 7.0 2025. These channels help address any issues that may arise during installation or daily usage.

Support can include online resources, user manuals, and direct assistance from representatives. Utilizing these resources can lead to quicker resolutions and enhanced user experience.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.