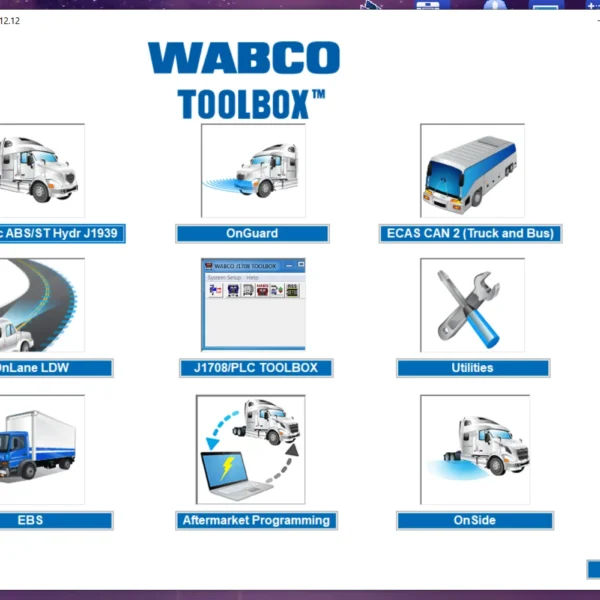

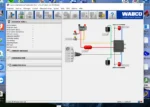

Wabco Tebs E 6 01: Revolutionizing Brake Control Systems for Heavy Vehicles

Wabco TEBS-E 6.01 is an advanced electronic brake control system designed for heavy vehicles. It enhances vehicle safety and performance by managing braking and traction effectively. Developed by Wabco, this system incorporates various technologies to optimize braking and improve stability. Its key components work together to ensure efficient operation under different driving conditions.

Background of Wabco and TEBS-E 6.01

The history and development of Wabco and the TEBS-E 6.01 system illustrate the evolution of brake technology for heavy vehicles. This section delves into Wabco’s origins, the advancements that led to TEBS technology, and the contributions of significant industry players like Scania.

History of Wabco

Wabco, established in 1869, has consistently led innovations in brake systems for commercial vehicles. Initially focused on air brake systems, the company expanded its offerings to include various control solutions. This evolution has been driven by a commitment to improving vehicle safety and operational efficiency.

Development of TEBS Technology

The development of TEBS technology marks a significant milestone in braking systems. TEBS, or Trailer Electronic Braking System, was designed to enhance brake performance while ensuring reliability. Over time, the integration of electronic components allowed for more precise control, making braking safer and more efficient in various driving conditions.

Role of Scania in TEBS Systems

Scania, as a prominent manufacturer of commercial vehicles, has played an essential role in the integration of TEBS technology into its trucks and buses. By collaborating with Wabco, Scania has helped to refine the systems, ensuring they meet the rigorous demands of the industry. This partnership has led to the successful deployment of advanced braking systems, enhancing overall road safety and performance.

Key Features of Wabco TEBS-E 6.01

The Wabco TEBS-E 6.01 incorporates several innovative features that set it apart in brake control technology, enhancing both safety and performance in heavy vehicles.

Electronic Brake Management

This system utilizes advanced electronic controls to manage braking functions precisely. The Electronic Control Unit (ECU) continuously analyzes data from various sensors, ensuring optimal brake response under diverse driving conditions. This electronic management allows for rapid adjustments, providing reliable stopping power while reducing the risk of wheel lock-up.

Traction Control System

The traction control system in the TEBS-E 6.01 plays a crucial role in preventing wheel spin during acceleration. By monitoring wheel speeds, it detects any slippage and modulates brake pressure accordingly. This feature is especially beneficial on slippery surfaces, enhancing vehicle stability and driver confidence.

Stability Optimization

Stability optimization is vital for maintaining vehicle control, particularly when carrying heavy loads. The TEBS-E 6.01 achieves this by adjusting brake force between the front and rear axles. This dynamic distribution of braking pressure not only improves overall stability during sudden stops but also minimizes the likelihood of rollover accidents.

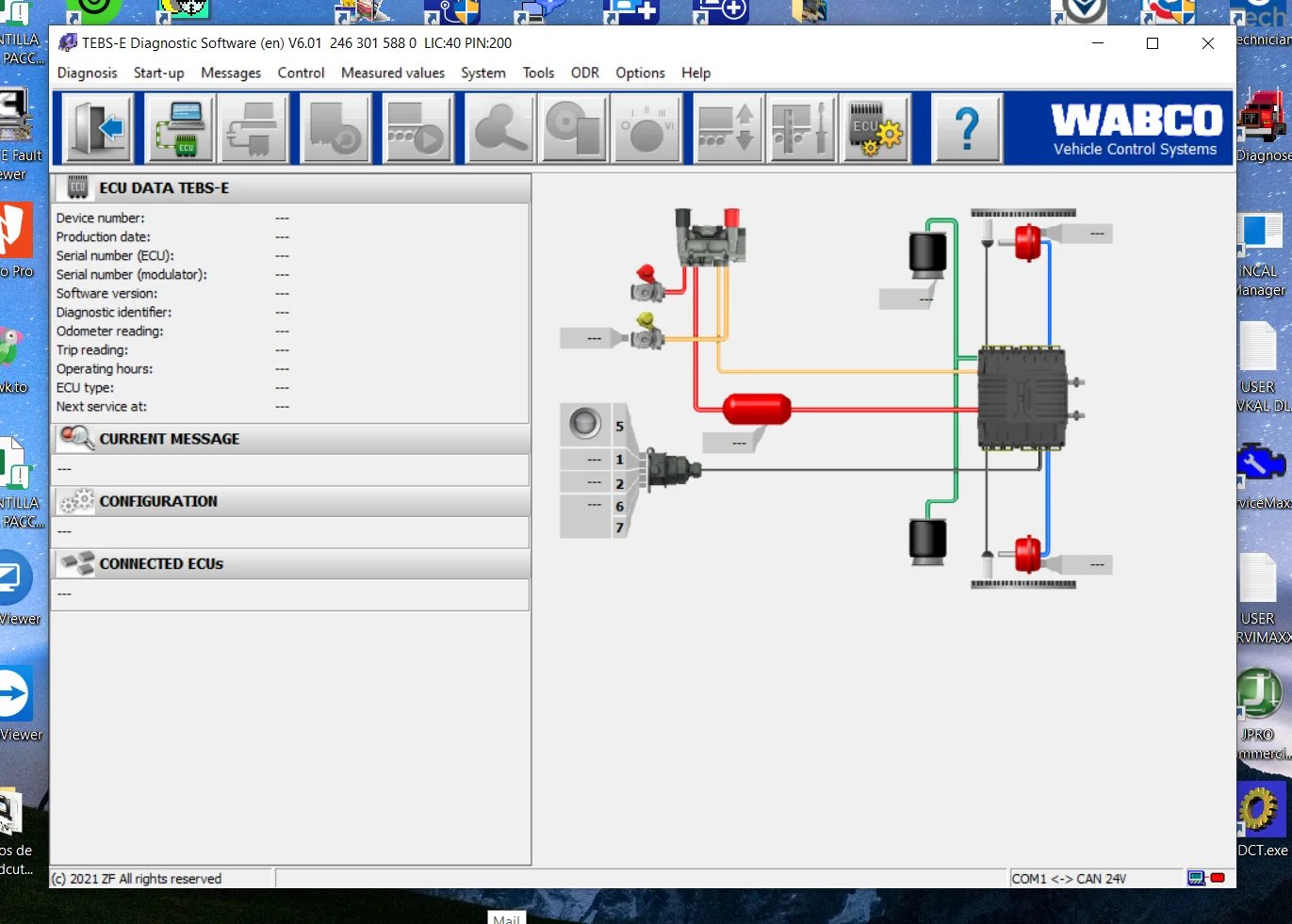

Components and Functionality

The Wabco TEBS-E 6.01 comprises a sophisticated arrangement of components designed to work in harmony, ensuring optimal functionality and safety during vehicle operation. Each part plays a pivotal role in enhancing the overall performance of the braking system.

Main Components

The key components of the TEBS-E 6.01 system include the following:

-

ECU (Electronic Control Unit)

The ECU serves as the brain of the braking system. It processes real-time data from various sensors to make instant decisions about brake application and control. This centralized unit allows for quick adjustments to improve braking efficiency.

-

Wheel Speed Sensors

These sensors monitor the rotation speed of each wheel, providing critical information to the ECU. The detection of any discrepancies in wheel speed helps prevent wheel lock-up and enhances traction control.

-

Control Valves

Control valves manage the distribution of air pressure to the brakes based on commands from the ECU. They ensure that brake force is applied appropriately to maintain vehicle stability.

Real-Time Operation

The functionality of the TEBS-E 6.01 is characterized by its ability to operate in real-time, adapting to changing driving conditions and demands.

Data Transmission and Processing

Data from wheel speed sensors is continuously transmitted to the ECU. This allows for rapid processing and immediate response, adjusting braking pressure as needed to optimize performance.

Brake Pressure Adjustment

Upon detecting any potential for wheel slip or instability, the ECU signals the control valves to modify brake pressure. This real-time adjustment ensures maximum grip while preventing over-braking, crucial for maintaining control in various road conditions.

The Wabco TEBS-E 6.01 offers various advantages that significantly enhance vehicle performance and operational efficiency.

Benefits of Using Wabco TEBS-E 6.01

Enhanced Road Safety

One of the primary advantages of the Wabco TEBS-E 6.01 is its remarkable contribution to road safety. The system is designed to minimize the risk of accidents through precise brake control. This is achieved by:

- Preventing wheel lock-up during emergency braking situations.

- Optimizing braking distance, particularly on slippery surfaces.

- Improving vehicle stability and control even under challenging driving conditions.

Fuel Efficiency Improvements

The introduction of the Wabco TEBS-E 6.01 also leads to significant fuel efficiency improvements. Efficient brake management directly influences operational costs.

Reduced Component Wear

By minimizing the stress on mechanical components during braking, the system contributes to prolonged equipment lifespan. This not only lowers maintenance expenses but also reduces the frequency of repairs.

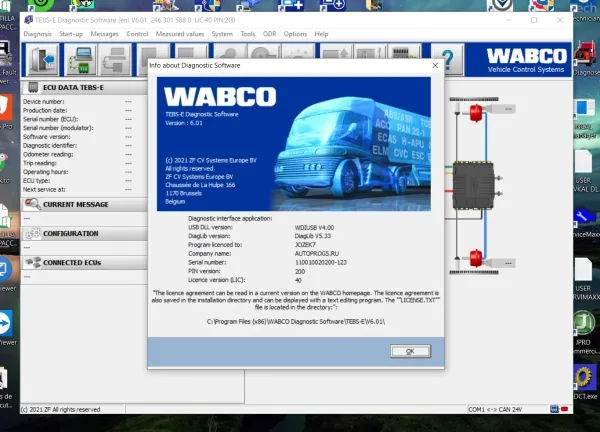

Simplified Maintenance

The maintenance process is streamlined with the integration of Wabco TEBS-E 6.01. This aspect plays a crucial role in reducing downtime and operational disruptions.

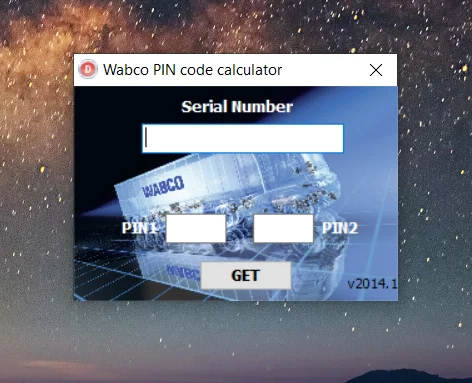

Diagnostic Tools

Designed with built-in diagnostic capabilities, the system allows for easy troubleshooting of issues. This facilitates quicker repairs and ensures optimal performance, ultimately enhancing vehicle reliability.

Comparison with Previous Systems

The Wabco TEBS-E 6.01 significantly improves upon prior braking systems, particularly the TEBS-A. These advancements enhance the overall safety and efficiency of heavy vehicles.

Advancements Over TEBS-A

The transition from TEBS-A to TEBS-E 6.01 marks a crucial technological leap for braking systems in commercial vehicles. Key improvements include:

- Increased precision in brake control processes.

- Enhanced operational response times, leading to better accident prevention.

- Integration of electronic systems that improve diagnostics and system monitoring.

Electronic vs. Mechanical Systems

The move from mechanical to electronic brake systems represents a fundamental shift in braking technology. Some advantages of electronic systems include:

- Dynamic Adjustments: Electronic systems can adjust braking force in real-time, optimizing performance based on changing road conditions.

- Reduced Wear: Specialized sensors minimize unnecessary braking, leading to less wear on components and a longer lifespan.

- Improved Data Analysis: Electronic systems provide extensive data for maintenance and performance analysis, enabling proactive solutions for operators.

Industry Implementation and Impact

The adoption of the Wabco TEBS-E 6.01 system has significantly transformed the heavy vehicle industry. Its integration has been driven by various factors that enhance safety and operational efficiency across the transportation sector.

Adoption Drivers

Key factors encouraging the adoption of TEBS-E 6.01 include regulatory compliance and an increased focus on safety standards in the industry.

Compliance with Safety Regulations

As regulations become more stringent, companies are compelled to implement advanced braking technologies. This not only ensures compliance but also promotes safer transportation practices.

Case Studies of Success

Numerous companies have reported substantial improvements in their operations following the implementation of the TEBS-E 6.01 system.

Accident Reduction Statistics

Statistics show that companies utilizing this system experience a marked decrease in accident rates. This underscores the system’s role in enhancing safety margins for fleet operations.

Future Trends in TEBS Technology

The future of TEBS technology seems promising, with ongoing advancements anticipated. Innovations in vehicle automation and communication systems are likely to play a pivotal role in further improving vehicle safety and monitoring systems.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.