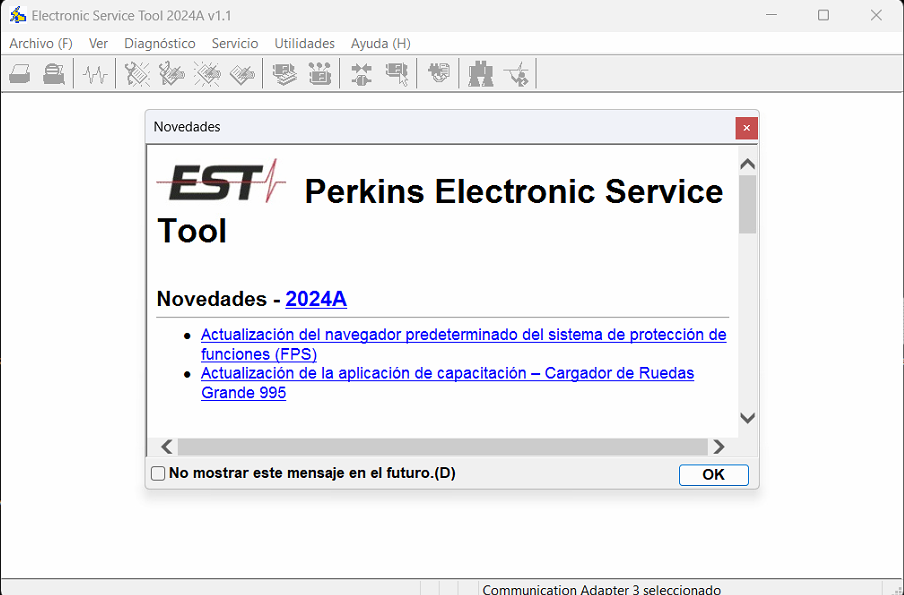

PERKINS EST 2024: The Ultimate Diagnostic Tool for Perkins Engines

Perkins EST 2024 is a specialized diagnostic tool designed for Perkins engines and generators. It provides users with the ability to troubleshoot issues, log data, and configure electronic control units effectively. This software includes a user-friendly interface and offers various diagnostic functions. It is compatible with multiple hardware devices and supports several languages, making it accessible to a global audience.

What is Perkins EST 2024?

Perkins EST 2024 is a cutting-edge diagnostic software tool specifically engineered for use with Perkins engines and generators. Created to streamline maintenance and troubleshooting processes, this software allows users to efficiently diagnose mechanical issues, record performance data, and configure electronic control units (ECM) through a streamlined communication link.

This advanced tool integrates various functionalities that facilitate the optimal performance of Perkins machinery. Through a user-friendly interface, technicians can access complex diagnostic data with ease, enabling quicker identification of potential problems. The software’s design prioritizes not only functionality but also accessibility, making it suitable for a wide range of users across different sectors.

One of the key components of Perkins EST 2024 is its ability to visualize diagnostics. Users can quickly see both active issues and historical data related to their engines. This capability is crucial for understanding the overall health of the equipment and ensuring preventive measures are taken before minor issues escalate into significant failures.

The tool also excels in recording and analyzing a wealth of parameter data, which helps users track engine performance trends over time. This level of monitoring aids in optimizing engine efficiency and can lead to better fuel consumption and lower operational costs.

Perkins EST 2024 is essential for professionals who rely on Perkins engines in various applications such as agriculture, construction, and marine settings. By providing insights into engine performance and potential anomalies, this tool supports operators in maintaining high uptime and maximizing the return on their investments.

Key Features of Perkins EST 2024

Perkins EST 2024 is equipped with a variety of advanced features aimed at enhancing the diagnostic process for users. These attributes ensure that technicians can perform maintenance and troubleshooting with efficiency and confidence.

User-Friendly Interface

The interface of Perkins EST 2024 is designed for ease of use. Technicians can navigate through various functions seamlessly, enabling quick diagnostics and reducing the learning curve associated with complex software systems. Intuitive menus and clear icons allow users to locate features without extensive training.

Diagnostic Functions

This tool offers a comprehensive suite of diagnostic capabilities that maximize its utility in maintenance scenarios.

Viewing Active and Logged Diagnostics

Users can easily view both active issues and past diagnostic logs. This feature provides immediate insight into ongoing problems, allowing for swift resolutions based on historical data.

Event Logs and Analysis

The event logging system records irregularities and operational events, offering technicians a detailed perspective on the engine’s performance over time. This logging is crucial for identifying patterns that could indicate underlying issues.

Status of Parameters

With this feature, users can monitor the status of multiple parameters at once. This simultaneous verification process aids in ensuring that all aspects of the engine are operating within specified limits, enhancing performance monitoring capabilities.

Data Recording and Performance Logs

Data recording functions enable ongoing monitoring and analysis of engine performance. By maintaining performance logs, technicians can assess the operational history and adjust maintenance schedules accordingly.

Calibration and Diagnostic Tests

The software includes tools for conducting calibrations and diagnostic tests. These functions ensure that the electronic control units (ECMs) maintain accurate settings, helping to optimize engine efficiency and effectiveness.

Printing Diagnostic Reports

Once diagnostics are complete, users can generate detailed reports to document findings and actions taken. These reports are invaluable for record-keeping and can also be used to inform customers of service results.

Multilanguage Support

Perkins EST 2024 supports multiple languages, making it accessible to a global user base. Language options include English, Spanish, French, German, and several others, ensuring comprehension for a diverse audience.

System Requirements

For optimal performance, Perkins EST 2024 requires a Windows operating system, specifically versions 8, 10, or 11. The installation size is approximately 1GB, which allows it to be easily installed on both laptops and desktop PCs used for diagnostic purposes.

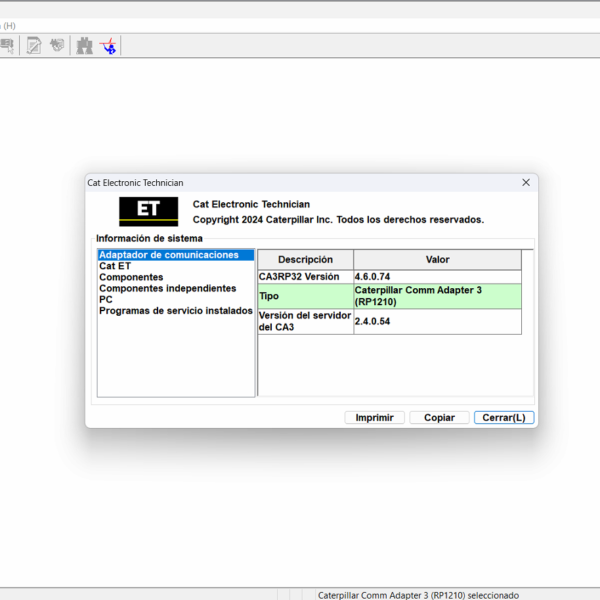

Compatible Hardware

The software is compatible with various data link adapters, which are essential for communication with Perkins engines. Some of the compatible devices include:

- CAT ET DataLink Adapter III

- Nexiq USB Link (Version 1 or 2)

- DG Technology DPA5

- Norgone DLA

- Other RP1210 devices

Software Updates and Support

Perkins provides regular software updates for EST 2024, ensuring users benefit from the latest features and improvements. Ongoing support from Perkins further enhances the user experience, allowing technicians to resolve any issues efficiently and remain informed about new capabilities.

Using Perkins EST 2024 for Engine Maintenance

The Perkins EST 2024 tool plays a crucial role in the maintenance of Perkins engines, enabling technicians to streamline their diagnostic and repair processes. This section outlines key functionalities that enhance engine upkeep.

Analyzing Engine Performance

Understanding and analyzing engine performance is vital for effective maintenance. The Perkins EST 2024 facilitates real-time monitoring of engine metrics, helping technicians identify areas for improvement. Key aspects include:

- Real-Time Data Monitoring: Users can continuously observe engine parameters such as temperature, pressure, and RPM.

- Performance Trends: Historical performance data can be analyzed to spot trends and predict potential issues.

- Instant Alerts: Notifications for deviations from normal operational thresholds help in prompt responses, minimizing downtime.

Modifying ECM Configurations

The capability to modify Electronic Control Module (ECM) configurations is one of the significant features offered by the Perkins EST 2024. This function allows users to tailor engine settings for optimal operation. Important actions include:

- Tuning Parameters: Adjust engine parameters to meet specific application needs, improving fuel efficiency and performance.

- Updating Firmware: Users can install firmware updates ensuring that the ECM operates with the latest software enhancements.

- Custom Specifications: Tailoring configurations based on operational requirements maximizes engine output and lifespan.

Password Authorization and Overrides

Security and access control are paramount when managing engine configurations. The Perkins EST 2024 provides facilities for password authorization, allowing technicians to override specific access restrictions. This is essential in various contexts such as:

- Advanced Settings Access: Technicians can gain access to advanced settings that usually require elevated permissions.

- Fault Recovery: In cases of ECM failures or lockouts, authorized technicians can quickly bypass restrictions to restore normal operations.

- Maintaining Operational Integrity: Access control ensures that only qualified personnel can make critical changes, safeguarding against errors.

Viewing and Logging ECM Irregularities

Monitoring engine irregularities is vital for maintaining optimal performance. The Perkins EST 2024 allows users to view and log irregularities detected by the ECM. This feature encompasses:

- Comprehensive Logs: Access to detailed logs of all recorded irregularities helps in diagnosing ongoing issues.

- Historical Data Comparison: Users can compare current irregularities against historical data to identify patterns or recurring issues.

- Predictive Maintenance: By analyzing logged irregularities, technicians can implement proactive maintenance strategies, enhancing overall reliability.

Application Sectors for Perkins EST

The Perkins EST 2024 tool is applicable across various sectors, highlighting its versatility and adaptability. From agriculture to marine applications, the tool enhances the efficiency and reliability of Perkins engines, catering to different operational needs.

Agriculture Equipment

In the agriculture sector, machinery relies heavily on durable and efficient engines. Perkins engines power a range of agricultural equipment, including:

- Tractors

- Harvesters

- Plows

- Irrigation systems

Using Perkins EST, technicians can quickly diagnose engine issues, ensuring farming equipment operates smoothly, thereby reducing downtime during critical seasons.

Construction Machinery

Construction machinery requires engines that can withstand demanding conditions. Perkins engines are commonly found in:

- Excavators

- Bulldozers

- Dump trucks

- Cranes

The Perkins EST 2024 tool aids in maintaining these machines by facilitating quick diagnostics and performance analysis, which is essential in the construction industry where project timelines are crucial.

Electrical Generators

Perkins engines are trusted power sources for electrical generators utilized in numerous settings, including residential, commercial, and industrial sectors. These engines provide reliable backup power solutions during outages. Perkins EST helps in:

- Monitoring generator performance

- Conducting preventive maintenance

- Identifying potential failures before they lead to power loss

This ensures that electrical systems remain operational, providing peace of mind to users.

Material Handling Equipment

In warehouses and distribution centers, material handling equipment must operate continuously. Perkins engines are integral to machines such as:

- Forklifts

- Pallet jacks

- Conveyor systems

The ability to monitor and optimize engine performance with Perkins EST 2024 significantly contributes to efficiency, helping to handle increased workloads without compromising safety.

Marine Engines

In the marine industry, reliability and durability are paramount. Perkins engines are utilized in various vessels, including:

- Fishing boats

- Yachts

- Workboats

Employing Perkins EST ensures that these marine engines remain in top condition, facilitating regular maintenance and quick resolution of issues that could impact navigation or operational performance. Proper diagnostics are critical in ensuring the safety of maritime operations.

Importance of Dedicated Diagnostic Tools

Dedicated diagnostic tools play a crucial role in maintaining the efficiency and longevity of engines. They enable users to identify issues proactively, ensuring that machinery remains operational and effective in various environments.

Minimizing Downtime

One of the primary advantages of using dedicated diagnostic tools is their ability to minimize downtime. Engines that experience unexpected failures can lead to significant operational disruptions and financial losses. By utilizing advanced diagnostic software, technicians can:

- Quickly identify issues, allowing for immediate troubleshooting.

- Access real-time data to assess engine performance and potential failures.

- Implement timely repairs or adjustments, reducing the time the equipment is out of service.

The increased speed in diagnosing and resolving problems translates directly into less downtime for machinery, making it an invaluable asset in industries where continuous operation is critical.

Adapting to New Technologies

The landscape of engine technology is continually evolving, with new functionalities and improvements being introduced regularly. Dedicated diagnostic tools are essential for adapting to these advancements. They allow technicians to:

- Stay current with the latest updates in engine software and hardware.

- Utilize features that enhance fuel efficiency and reduce emissions, aligning with modern environmental standards.

- Integrate advanced technologies into existing systems for improved performance.

By keeping pace with technological developments, organizations can optimize their operations and ensure their engines operate at peak efficiency. This adaptability helps companies remain competitive in an ever-changing market.

Investing in Perkins EST 2024

Investing in Perkins EST 2024 brings significant advantages for businesses relying on Perkins engines. This decision is influenced by factors such as cost considerations and the long-term benefits the tool provides.

Cost Considerations

When evaluating the investment in Perkins EST 2024, it is essential to assess the overall costs associated with acquiring and maintaining the tool. Here are some key points to consider:

- Initial Purchase Price: The upfront costs may vary depending on the features and support options chosen.

- Hardware Compatibility: Ensuring that existing diagnostic hardware is compatible can impact total investment costs.

- Training and Implementation: Budgeting for training staff to maximize the software’s potential is crucial for a successful implementation.

- Software Updates: Regular updates may be necessary to enhance features and maintain functionality, which could incur additional costs over time.

- Support Services: Factoring in ongoing support services can help maintain seamless operations and quick troubleshooting when needed.

Long-Term Benefits

The long-term benefits of investing in Perkins EST 2024 can significantly outweigh the initial costs. Businesses can anticipate various advantages, including:

- Optimized Performance: Continuous monitoring and diagnostics lead to improved engine performance and reduced operational costs.

- Troubleshooting Efficiency: The ability to quickly identify and address issues minimizes downtime and enhances productivity.

- Data-Driven Decisions: Access to real-time data allows for informed decision-making regarding maintenance and optimization strategies.

- Extended Equipment Lifespan: Regular diagnostic checks can extend the life of the engines, leading to lower replacement costs over time.

- Competitive Advantage: Utilizing advanced diagnostic tools can give businesses an edge in their respective industries by ensuring reliable and efficient equipment operation.

FAQs About Perkins EST 2024

This section addresses frequently asked questions regarding Perkins EST 2024, providing users with essential information and clarifications on common concerns and technical support.

Common User Questions

- What types of engines are compatible with Perkins EST 2024?Perkins EST 2024 is designed to work with a wide array of Perkins engines and generators. This includes various models utilized in agriculture, construction, marine, and material handling applications. Users should verify compatibility with specific engine models to ensure optimal performance.

- How often are software updates released for Perkins EST 2024?Perkins regularly provides software updates for EST 2024 to improve functionality and maintain compatibility with the latest engine models. Users are encouraged to check for updates periodically to benefit from new features and enhancements.

- Can Perkins EST 2024 be used on more than one device?Yes, Perkins EST 2024 can be installed on multiple computers, provided that the software license agreements are adhered to. This allows technicians to have access to the diagnostic tool across various workstations or service locations, enhancing efficiency.

- Are there training resources available for new users?Training resources, including manuals, video tutorials, and user guides, are available to help new users familiarize themselves with Perkins EST 2024. These materials aim to facilitate effective use of the diagnostic tool and ensure that users can leverage its full capabilities.

Technical Support Information

- What support options are available for Perkins EST 2024 users?Users of Perkins EST 2024 can access multiple support options, including online resources, FAQs, and technical helplines. These services are designed to assist with troubleshooting and operational queries.

- Is there a warranty for Perkins EST 2024 software?The software generally comes with a warranty that covers defects in software functionality. Users should refer to the specific warranty terms provided at the time of purchase to understand coverage details.

- How can users report a bug or issue with the software?Users can report bugs or software issues through official support channels. Providing detailed information about the problem, including screenshots if applicable, can expedite the support process and lead to quicker resolutions.

- What should users do if they forget their software access password?In the event of a forgotten password, users should follow the password recovery process outlined in the user manual or on the software interface. This generally involves security questions or contacting support for password reset assistance.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

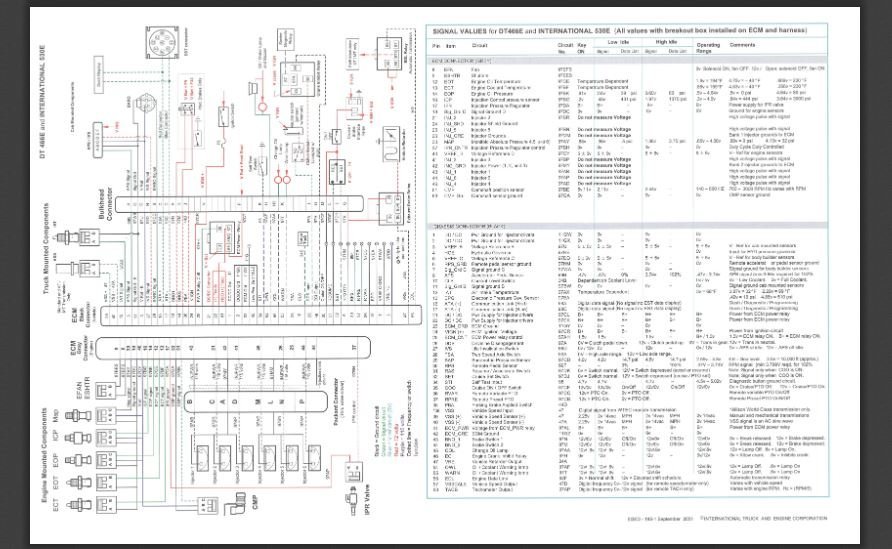

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.