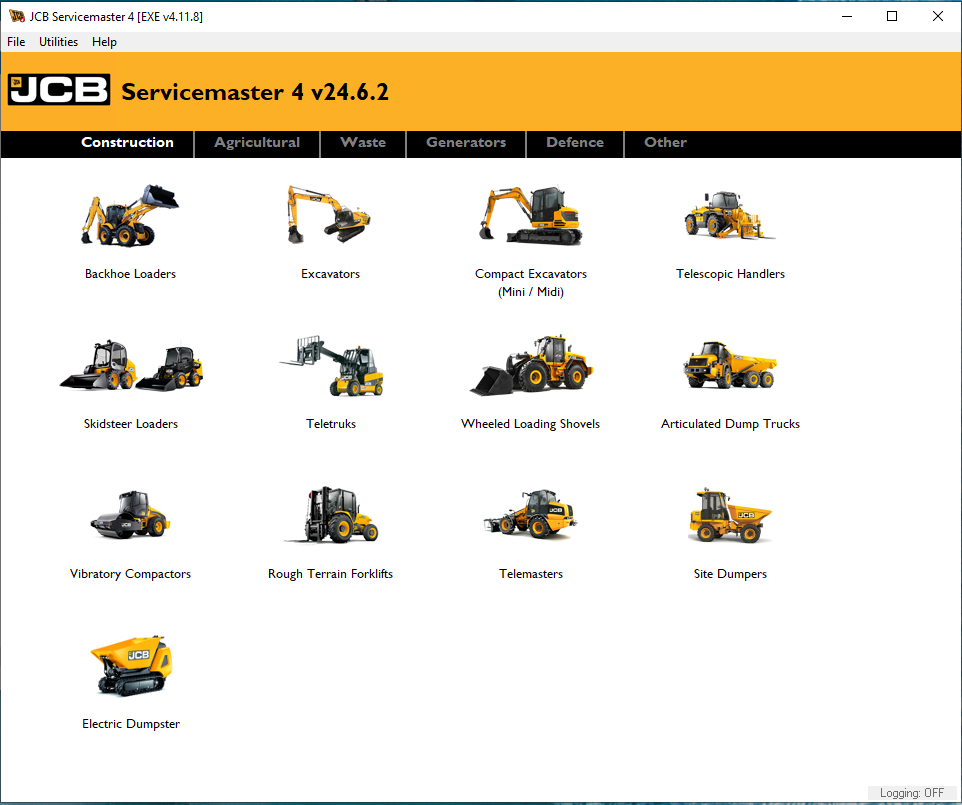

JCB ServiceMaster Diagnostic Software 24 6 2 2024: Your Essential Tool for Heavy Machinery Maintenance

JCB ServiceMaster Diagnostic Software 24 6 2 2024 provides essential diagnostic tools for JCB machinery. This software enables users to identify issues quickly and efficiently, improving overall machinery performance. The latest version includes enhanced features and a user-friendly interface. Compatibility with various JCB equipment ensures it meets the needs of different operators in the agricultural and construction sectors.

Understanding JCB ServiceMaster Diagnostic Software

The JCB ServiceMaster Diagnostic Software is an advanced tool designed for effective machinery diagnostics. It serves technicians by providing essential insights into machinery performance and potential issues.

Key Features and Benefits

This software brings a range of features that enhance operational efficiency. Some key benefits include:

- Rapid diagnostic capabilities to quickly identify and resolve mechanical issues.

- Real-time monitoring of various systems and components of the machinery.

- Availability of detailed reports that aid in understanding equipment conditions.

Compatibility with JCB Equipment

The software is designed to work seamlessly with different models of JCB machinery. Its compatibility ensures that users can effectively utilize it across various equipment types.

Fastrac Tractors Integration

Fastrac tractors can benefit significantly from the diagnostic software. It provides specific diagnostics tailored for these machines, allowing for maintenance and repairs that keep them operating at peak performance.

Wheeled Loading Shovels Compatibility

This software also offers comprehensive support for wheeled loading shovels. Through its diagnostic tools, technicians can monitor system health, leading to better maintenance practices and reduced downtime.

User Interface Enhancements

The latest version of the software features significant user interface upgrades, making navigation intuitive. Users can easily access various functions and understand the diagnostic results without extensive training.

Installation and System Requirements

To ensure optimal performance of the diagnostic software, specific installation and system requirements must be met. This section outlines the necessary steps and hardware specifications needed to successfully set up the software.

Steps for First Time Setup

Installing the software requires a straightforward process. Follow these steps:

- Download the installation package from the official source.

- Run the installer and follow the on-screen prompts.

- Review the license agreement and accept the terms.

- Select the installation directory and initiate the installation.

- Once installation is complete, restart your computer if prompted.

Minimum Hardware Specifications

Before installation, ensure that your system meets the following minimum hardware requirements:

- Operating System: Windows 10 or later

- RAM: At least 4 GB

- Hard Disk Space: Minimum of 1 GB of free space

- Processor: 2.0 GHz Dual-Core or equivalent

- Network Connection: Stable internet for updates

Recommended System Configurations

For improved performance and user experience, the following configurations are recommended:

- Operating System: Windows 10 Pro or Windows 11

- RAM: 8 GB or more

- Hard Disk: SSD with at least 2 GB of free space

- Processor: 3.0 GHz Quad-Core or higher

Common Installation Issues and Solutions

During installation, users may encounter various issues. Some common problems and their solutions include:

- Installation Fails: Ensure your operating system is compatible and check for enough disk space.

- Software Not Launching: Verify that all required system specifications are met or reinstall the software.

- Connectivity Issues: Confirm that the internet connection is stable and your firewall settings allow the software to connect.

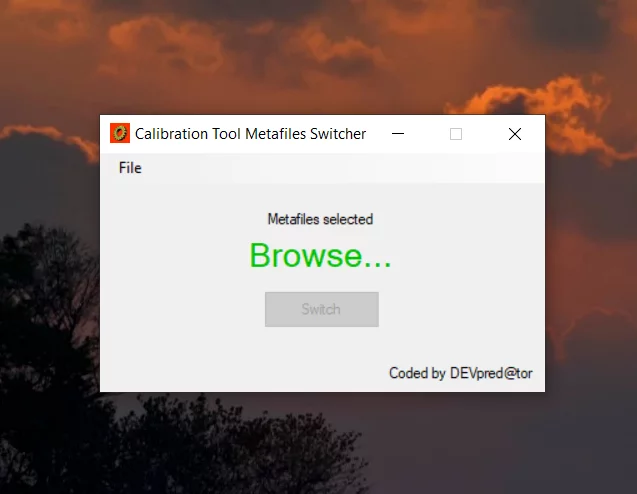

Using the Diagnostic Software

The JCB ServiceMaster Diagnostic Software is designed to streamline the diagnostic process for machinery, enabling quick and effective troubleshooting.

Real-Time Diagnostic Capabilities

This software enables technicians to perform diagnostics while machinery is in operation. Real-time monitoring allows for immediate feedback on the status of key components. Critical parameters are assessed, ensuring that any potential issues can be addressed promptly.

Generating and Interpreting Reports

Once diagnostics are performed, the software generates detailed reports. These reports provide insights into:

- Error codes and descriptions

- Status of various machinery systems

- Recommendations for repairs or further action

Understanding these reports is essential for effective maintenance and can significantly improve troubleshooting efficiency.

Maintenance and Repair Applications

The diagnostic software plays a crucial role in both maintenance and repair tasks. It supports technicians in identifying problems early while also offering solutions for repairs.

Proactive Maintenance Strategies

Implementing a proactive maintenance strategy is facilitated by the software’s capabilities. Regular diagnostics can help in:

- Identifying wear and tear before it leads to equipment failure

- Scheduling necessary maintenance ahead of time

- Enhancing the longevity of machinery by addressing minor issues promptly

This proactive approach not only minimizes downtime but also reduces overall maintenance costs, resulting in enhanced operational efficiency.

Purchase Options and Pricing

Various purchase options are available for acquiring the JCB ServiceMaster Diagnostic Software 24 6 2 2024. Understanding these options will help users select the best fit for their needs and budget.

Software Only Package

This package provides customers with the JCB ServiceMaster software alone, allowing for installation on existing hardware. It is designed for professionals who already possess compatible equipment and prefer a cost-effective solution.

- Price: $798.00

Software with Tools Bundle

The tools bundle option includes the software along with additional diagnostic tools. These tools are specifically designed to enhance diagnostic capabilities and improve maintenance procedures.

- Price: $827.00

Complete Purchase with Pre-installed Laptop

This comprehensive option offers the software already installed on a compatible laptop. This package is perfect for users who prefer a ready-to-use solution without the need to set up the software themselves.

- Price: $1,209.00

Support and Service Information

This section outlines the support and service options available for users of the JCB ServiceMaster Diagnostic Software. Access to reliable resources and timely assistance is crucial for maximizing the software’s potential.

Comparing with Other Diagnostic Tools

In a competitive marketplace, understanding how diagnostic tools measure up against each other is essential for optimal machinery maintenance.

JCB Diagnostic Tool Advantages

The JCB ServiceMaster Diagnostic Software is designed specifically for JCB machinery, providing several key advantages:

- Comprehensive diagnostics tailored for JCB models.

- Real-time reporting capabilities that enhance troubleshooting.

- User-friendly interface suitable for various skill levels.

How It Stacks Against Competitors

When compared to other diagnostic software, JCB ServiceMaster demonstrates distinct strengths and features.

CAT ET Diagnostic Software

Caterpillar’s CAT ET diagnostic tool is focused on Caterpillar equipment. It excels in fault codes and service information but lacks the multilingual support that JCB ServiceMaster offers. Its usability can be more complex for non-expert users.

John Deere Service Advisor

The John Deere Service Advisor provides excellent diagnostics for John Deere machinery similar to JCB ServiceMaster. However, it is limited to John Deere models, missing the versatility that JCB software provides for various machinery types. Additionally, the cost can be significantly higher.

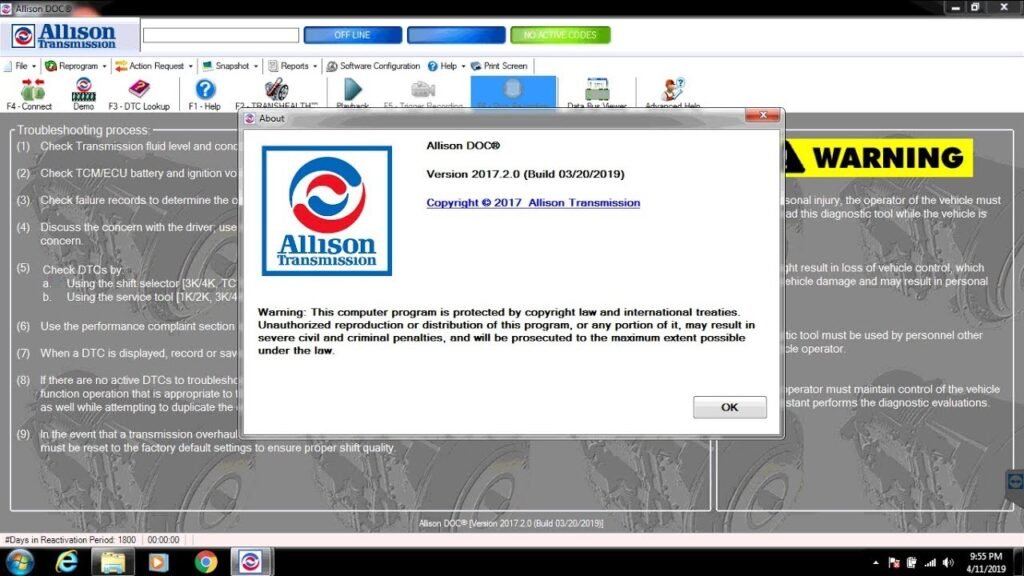

AGCO

AGCO ALLISON

ALLISON BENDIX

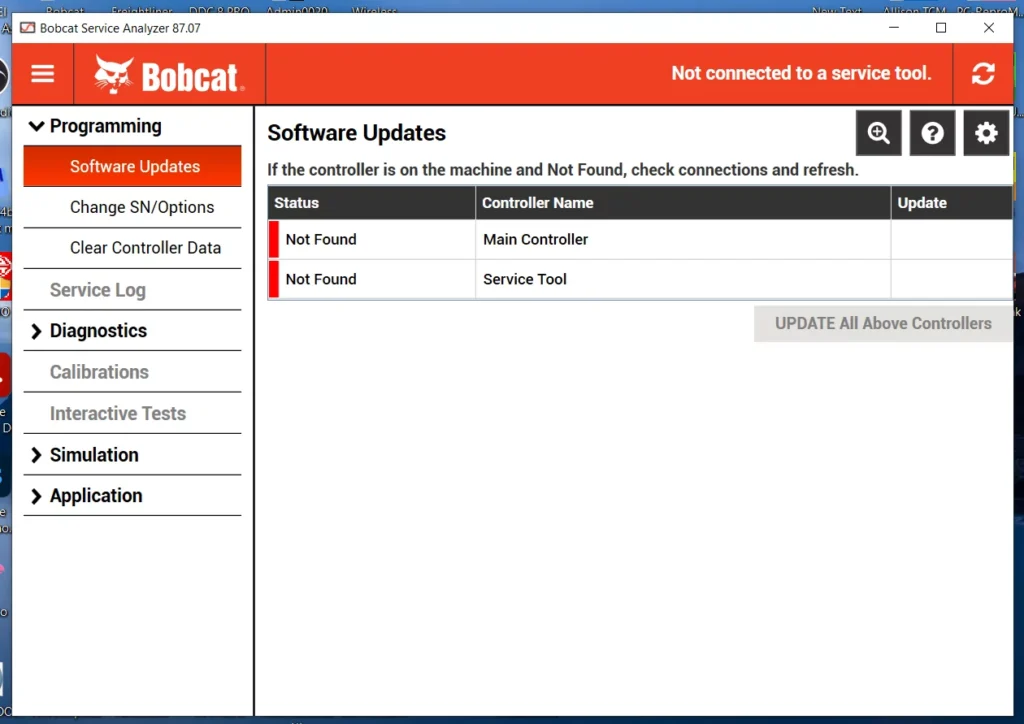

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.