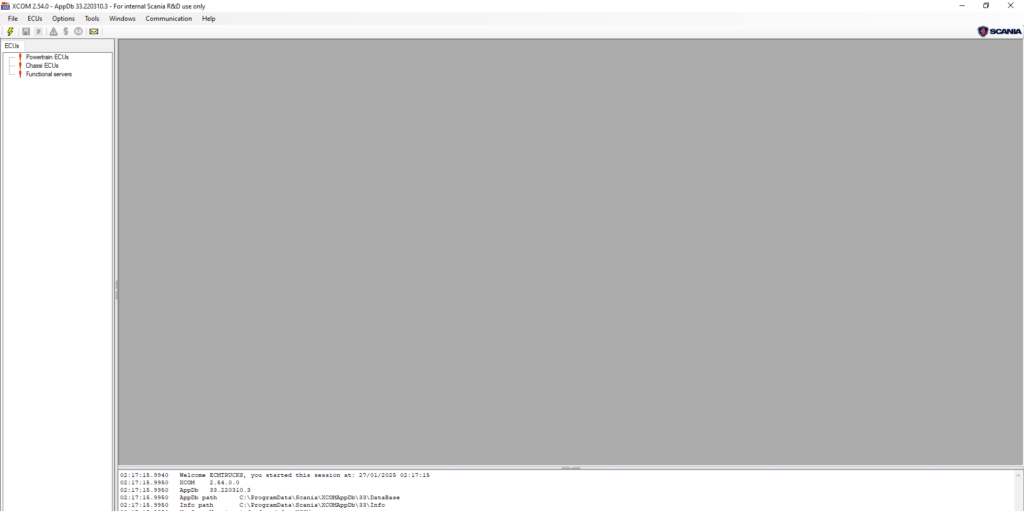

JCB AGCO SISU POWER WINEEM4 2.9: Essential Diagnostic Tool for Engines

JCB AGCO SISU POWER WinEEM4 2.9 is a key diagnostic tool for heavy machinery. It is designed to improve the efficiency and accuracy of engine diagnostics in agricultural and construction equipment. With various features, including fault code reading and ECU activation, WinEEM4 aids technicians in identifying issues quickly. The software supports multiple operating systems and offers crucial information for effective maintenance.

Overview of JCB AGCO SISU POWER WinEEM4 2.9

The JCB AGCO SISU POWER WinEEM4 2.9 serves as a crucial component in modern machinery diagnostics. Its advanced technology aids in analyzing and troubleshooting heavy equipment, ensuring optimal performance.

Importance in Heavy Equipment Diagnostics

This tool significantly enhances maintenance procedures by providing detailed diagnostics for engines equipped with AGCO Power technology. By facilitating swift identification of issues, it minimizes downtime and boosts operational efficiency for technicians working with both agricultural and construction machinery.

Compatibility and Language Support

Offering broad compatibility, WinEEM4 2.9 is designed to operate on various systems, ensuring it meets the diverse needs in the field.

Supported Operating Systems

- Windows 7

- Windows 8

- Windows 10

Language Capabilities

- English

Key Features of WinEEM4

WinEEM4 offers distinct features that enhance diagnostic efficiency for heavy machinery. Its robust capabilities support effective troubleshooting and maintenance.

Diagnostic Capabilities

This tool is equipped with advanced diagnostic functions essential for technicians.

Fault Code Reading and Analysis

WinEEM4 allows users to read and analyze fault codes seamlessly. This feature helps identify engine issues quickly, minimizing downtime. The clear descriptions provided for each code aid in understanding the underlying problems, enabling speedy resolutions.

Real-time Data Monitoring

WinEEM4 provides real-time data monitoring, which is crucial during diagnostics. Technicians can assess engine performance metrics live, allowing them to track parameters like RPM, temperature, and pressure while the machinery is operating. This functionality supports immediate adjustments and accurate fault diagnostics.

Service Operations

The software also includes essential service operations that contribute to effective machinery maintenance.

ECU Activation

With the ECU activation feature, users can enable the engine control unit to perform various tests. This function is critical in ensuring the ECU is operational and can carry out necessary functions as intended.

Motor Testing Procedures

WinEEM4 facilitates various motor testing procedures, supporting comprehensive evaluations. Technicians can perform tests to assess the motor’s functionality, identify malfunctions, and verify performance standards, ensuring machinery operates efficiently.

Installation and Activation Process

The installation and activation process for the diagnostic software involves a few straightforward steps, ensuring that users can get started efficiently. This section outlines the key procedures for obtaining and setting up the software.

Purchase and Download

To begin, the software must be purchased from a trusted vendor. Once the purchase is confirmed, the user receives a secure download link for the software. It is crucial to ensure that the download is completed from a reliable source to avoid issues with the software.

Installation Steps

Once the download is completed, follow these installation steps:

- Locate the downloaded file on the computer.

- Double-click the file to initiate the installation process.

- Follow the on-screen instructions, which typically guide the user through a straightforward installation wizard.

- When prompted, agree to the software terms and conditions.

- Complete the installation, ensuring that all necessary components are properly set up.

Activation Requirements

After installation, users need to activate the software to unlock its full capabilities. This generally requires the following:

- Enter a unique license key, which is usually provided upon purchase.

- Ensure an active internet connection, as the activation process may require online verification.

- Keep the license information secure for future use or updates.

Benefits of Using WinEEM4 for Maintenance

The WinEEM4 diagnostic tool offers significant advantages for maintenance processes in heavy machinery. Its features enhance efficiency and reliability, ultimately leading to substantial improvements in operational performance.

Time and Cost Efficiency

One of the primary benefits of using WinEEM4 is the ability to reduce both time and costs associated with maintenance operations. By providing quick and accurate diagnostics, this tool minimizes the duration of repairs and helps save on labor costs. This efficiency translates into significant savings for businesses relying on heavy equipment.

Enhanced Performance and Reliability

The use of WinEEM4 leads to improved overall performance of machinery. This tool helps maintain systems in optimal condition, thus enhancing their reliability during operation.

Reduction in Downtime

Reducing downtime is crucial in the machinery industry. WinEEM4 allows for faster identification of issues, which means repairs can be conducted swiftly. This is particularly important for companies that rely on heavy equipment to meet project deadlines.

Improved Equipment Longevity

Regular and effective diagnostics facilitated by WinEEM4 contribute to increased equipment longevity. By addressing issues before they escalate into major failures, the tool helps extend the lifespan of machinery. This proactive approach leads to fewer replacements and higher return on investment for equipment owners.

Comparisons with Other Diagnostic Tools

Examining how JCB AGCO SISU POWER WinEEM4 2.9 stacks up against its competitors reveals key differences and advantages that may influence user choice.

Differences with Caterpillar ET

While both tools serve the heavy equipment sector, the JCB WinEEM4 has unique features that set it apart:

- Diagnostic Flexibility: WinEEM4 supports a broader range of engines, particularly in agricultural machinery.

- User Interface: Many users find the WinEEM4 interface more intuitive, which aids technicians of all skill levels.

- Cost-Effectiveness: The installation and activation costs for WinEEM4 are generally lower than those associated with Caterpillar ET.

Advantages over Doosan DMS-5

The JCB AGCO SISU POWER WinEEM4 offers several advantages compared to Doosan DMS-5:

- Broader Compatibility: It works effectively with a wider array of AGCO Power engines, enhancing its utility in the field.

- Advanced Diagnostic Features: The real-time data monitoring capability in WinEEM4 provides more in-depth insights into engine performance.

- Enhanced Support: Users often report more robust customer support options with JCB compared to Doosan, making troubleshooting faster and easier.

Practical Applications in Heavy Machinery

This section outlines the real-world applications of the diagnostic tool in the field of heavy machinery, particularly within agricultural and construction environments.

Use in Agricultural and Construction Equipment

The application of diagnostic tools like the JCB AGCO SISU POWER WinEEM4 2.9 is crucial in both agricultural and construction sectors. These tools streamline the maintenance processes, leading to enhanced equipment efficiency. Some of the key uses include:

- Monitoring engine performance metrics in real-time.

- Identifying faults in electronic control units (ECUs).

- Performing necessary adjustments to ensure optimal machinery operation.

Real-life Success Stories

Numerous professionals in the industry have reported tangible success by integrating the WinEEM4 diagnostic tool into their workflows.

Case Study: Construction Company

In a recent case, a construction company implemented the WinEEM4 within their maintenance routine. This led to:

- A 30% decrease in downtime due to faster fault identification.

- Improved project completion rates, staying within budget.

User Testimonials on Efficiency Gains

Operators have shared positive feedback regarding the tool’s impact on their operations. Notable comments include:

- “The ability to diagnose issues quickly has transformed our maintenance approach.”

- “We noticed significant savings in time and costs after using this tool.”

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.