Circuit Description

The engine aftertreatment system monitors the soot load in the aftertreatment diesel particulate filter. Under normal operating conditions, the aftertreatment diesel particulate filter is self-cleaning, where soot is converted to carbon dioxide, nitrogen, and water. Under light load operating conditions, it can be necessary to perform a stationary regeneration of the aftertreatment diesel particulate filter. The soot load in the aftertreatment diesel particulate filter is estimated, using the aftertreatment differential pressure sensor and the calculated soot output of the engine.

Component Location

The aftertreatment diesel particulate filter is located in the exhaust system and is installed by the original equipment manufacturer. See the equipment manufacturer service information.

Conditions for Running the Diagnostics

This diagnostic runs continuously when the engine speed is greater than 500 rpm.

Conditions for Setting the Fault Codes

The engine control module (ECM) detects that the diesel particulate filter is plugged or that the differential pressure across the diesel particulate filter is above the maximum limits.

Action Taken When the Fault Code is Active

The ECM illuminates the amber CHECK ENGINE lamp and/or the malfunction indicator lamp (MIL) immediately when the diagnostic runs and fails.

The exhaust gas recirculation (EGR) valve operation will be disabled.

Conditions for Clearing the Fault Code

To validate the repair, start the engine and let it idle for 1 minute.

The fault code status displayed by INSITE? electronic service tool will change to INACTIVE immediately after the differential pressure across the aftertreatment diesel particulate filter has dropped below the maximum severity level and the diagnostic runs and passes.

The ECM will turn off the amber CHECK ENGINE lamp after the diagnostic runs and passes.

For On-Board Diagnostics (OBD) engines, the ECM will turn off the MIL after three consecutive trips where the diagnostic runs and passes.

The ?Reset All Faults? command in INSITE? electronic service tool can be used to clear active and inactive fault codes, as well as extinguish the MIL for OBD applications.

Shop Talk

Possible causes of this fault code include:

The aftertreatment wiring harness connectors may be connected to the wrong aftertreatment temperature sensor.

The aftertreatment wiring harness or aftertreatment temperature sensor connector pin installation may be incorrect.

The aftertreatment diesel particulate filter can be plugged with ash.

The engine has been operating in light load conditions that prevent exhaust gas temperatures from being high enough to actively regenerate the aftertreatment particulate trap.

An engine malfunction that is elevating the engine smoke output.Excessive ash in the DPF

Excessive ash in the DPF.

Reference the appropriate equipment manufacturer wiring diagram when troubleshooting circuits that utilize wiring supplied by the equipment manufacturer.

For intermittent power supply and datalink communication issues with Aftertreatment Components, it is highly recommended that the equipment manufacturer Power Distribution Center fuses and relays be thoroughly checked for loose, missing or intermittent connections.

Possible Cause:

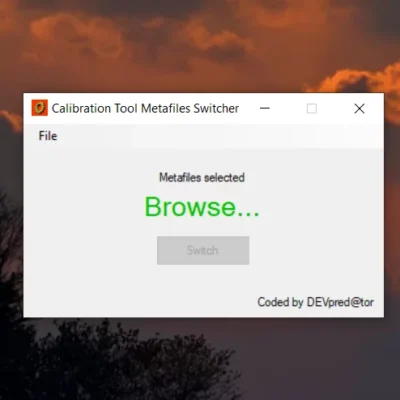

1) ECM calibration

2) Aftertreatment DPF differential pressure sensor failure

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

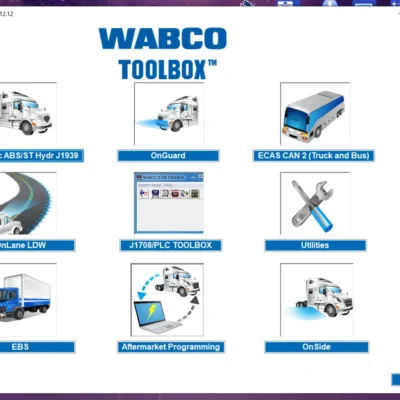

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.