Cummins ISB6.7 CM2350 (2013-17) Fault Code: 3148 PID: SPN: 4363 FMI: 2 Aftertreatment 1 SCR Outlet Temperature Sensor- Data Erratic, Intermittent, or Incorrect

Circuit Description

The aftertreatment SCR (selective catalytic reduction) temperature sensor module is a smart device that communicates with the engine control module via the J1939 data link. The aftertreatment SCR temperature sensor module performs its own internal diagnostics and reports malfunctions back to the engine control module using the J1939 data link. The aftertreatment SCR temperature sensor module is used to measure the aftertreatment SCR intermediate temperature and aftertreatment SCR outlet temperature. The temperature probes are permanently attached to the aftertreatment SCR temperature sensor module and can not be replaced individually.

Component Location

The aftertreatment SCR temperature sensor module is mounted on the aftertreatment SCR catalyst.

Conditions for Running the Diagnostics

This diagnostic runs when the exhaust gas temperature sensors are compared to other engine temperatures during engine operation. The engine coolant temperature must be above 60?C [140?F] before the diagnostic will run.

Conditions for Setting the Fault Codes

The Engine Control Module (ECM) detected the aftertreatment SCR outlet temperature sensor signal was irrational for more than 5 minutes.

Action Taken When the Fault Code is Active

The ECM illuminates the amber CHECK ENGINE lamp and/or Malfunction Indicator Lamp (MIL) after the diagnostic fails on two consecutive trips.

A default value for the SCR catalyst outlet temperature is used.

1)Diesel exhaust fluid injection into the aftertreatment system is disabled.

2)Engine torque will be reduced if the engine is operated for an extended period of time with this fault active.

Conditions for Clearing the Fault Code

1)To validate the repair using a Diagnostic Road Test, utilize a route that incorporates both stop and go city type driving and steady state highway type driving. It may be necessary to load the unit for certain diagnostics in the ECM to run.

2)To validate the repair using a Chassis Dynamometer, utilize a routine that incorporates acceleration and motoring events, steady state highway type operation, and load. This will simulate normal driving and allow the diagnostics in the ECM to run.

3)The fault code status displayed by INSITE? electronic service tool will change to INACTIVE immediately after the diagnostic runs and passes.

4)The ECM will turn off the amber CHECK ENGINE lamp immediately after the diagnostic runs and passes.

5)For On-Board Diagnostics (OBD) engines, the ECM will extinguish the Malfunction Indicator Lamp (MIL) after three consecutive trips where the diagnostic runs and passes.

6)The Reset All Faults command in INSITE? electronic service tool can be used to clear active and inactive faults, as well as extinguish the MIL for OBD applications.

Possible causes:

1) A malfunctioning aftertreatment SCR outlet temperature sensor

Reference the appropriate OEM wiring diagram when troubleshooting circuits that utilize wiring supplied by the OEM.

For intermittent power supply and datalink communication issues with Aftertreatment Components, it is highly recommended that the OEM Power Distribution Center fuses and relays be thoroughly checked for loose, missing or intermittent connections.

AGCO

AGCO ALLISON

ALLISON BENDIX

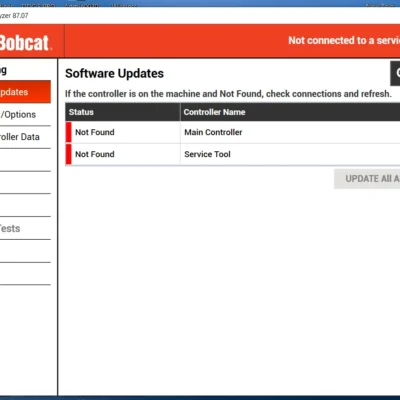

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![JCB Service Master 4 Diagnostic Software is a powerful tool for professionals in the automotive and heavy machinery industry. With its easy-to-use interface, it provides a wide range of diagnostic and calibration functions for JCB machinery and engines. From construction to agricultural equipment, this software supports various JCB models, ensuring optimal performance and safety. It also offers programming capabilities and a language editing tool. Maximize your diagnostic efficiency and reliability with JCB Service Master 4 v21.4.2 [05.2021] from ecmtrucks.com.](https://ecmtrucks.com/wp-content/uploads/2024/01/JCB-servicemaster-4-400x400.webp)

Reviews

Clear filtersThere are no reviews yet.