Circuit Description

Normally, switches, accelerators, and other components are connected to the engine control module (ECM) directly through individual wires. Multiplexing allows those same components to be hard wired to an original equipment manufacturer (OEM) vehicle electronic control unit or transmission electronic control unit in the cab. Then component values and states from components such as sensors, accelerators, and switches can be transmitted from the OEM vehicle engine control unit to the Cummins® ECM over the SAE J1939 data link.

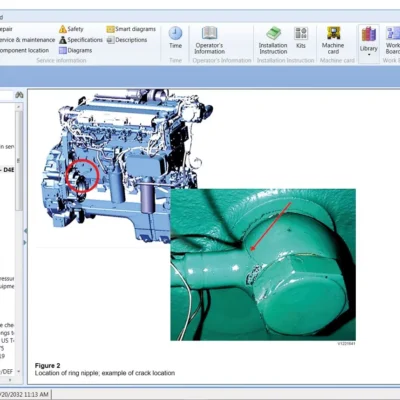

Component Location

The SAE J1939 data link wiring and SAE J1939 devices vary by OEM options.

Conditions for Running the Diagnostics

This diagnostic runs continuously when the keyswitch is in the ON position or when the engine is running.

Conditions for Setting the Fault Codes

The ECM detects a loss of communication with the Engine Wait to Start Lamp.

Action Taken When the Fault Code is Active

-The ECM illuminates the amber CHECK ENGINE lamp and/or the malfunction indicator lamp (MIL) immediately when the diagnostic runs and fails.

Conditions for Clearing the Fault Code

-To validate the repair, perform a key cycle, start the engine, and let it idle for 1 minute.

-The fault code status displayed by INSITE™ electronic service tool will change to INACTIVE immediately after the diagnostic runs and passes.

-The ECM will turn off the amber CHECK ENGINE lamp immediately after the diagnostic runs and passes.

-For On-Board Diagnostics (OBD) engines, the ECM will extinguish the MIL after three consecutive trips where the diagnostic runs and passes.

-The “Reset All Faults” command in INSITE™ electronic service tool can be used to clear active and inactive faults, as well as extinguish the MIL for OBD applications.

Possible Causes

-Incorrect terminating resistance of the SAE J1939 data link circuit

-Incorrect feature and parameter settings

-A malfunctioning SAE J1939 data link circuit.

AGCO

AGCO ALLISON

ALLISON BENDIX

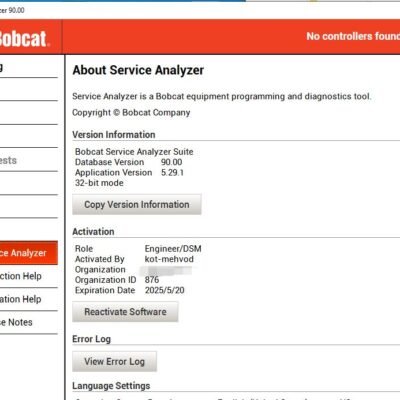

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

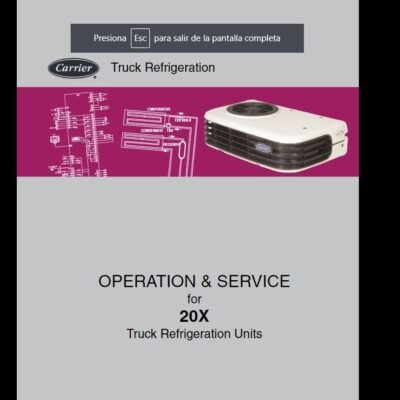

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

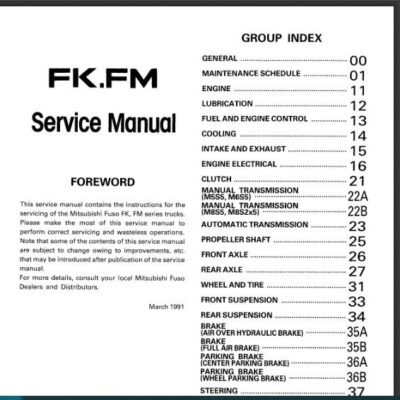

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.