DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06]: Essential Diagnostic Tool for Heavy Machinery

DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06] is a vital diagnostic software designed for heavy machinery. It provides users with tools for efficient maintenance and monitoring of DOOSAN trucks and equipment. This software simplifies problem identification and performance tracking. It also offers support for remote installations using TeamViewer, making it accessible and user-friendly for operators and technicians.

Product Overview

The Product Overview section provides essential insights into the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 [2023.06] software. This software is designed to enhance diagnostic and maintenance capabilities for heavy machinery.

Description and Purpose

DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 is a sophisticated diagnostic tool tailored for heavy trucks and machinery, specifically those manufactured by DOOSAN. The software aims to streamline maintenance processes by providing users with an intuitive interface that facilitates real-time diagnostics and monitoring of machine performance. This tool’s purpose is to help operators identify issues quickly and efficiently, ultimately minimizing downtime and enhancing productivity across various operational contexts.

Key Features

This software comes equipped with several key features that set it apart in the market:

- Advanced Diagnostics: Capability to perform in-depth analyses of machine systems to identify potential problems.

- Performance Monitoring: Continuous tracking of equipment efficiency and function to predict maintenance needs.

- User-Friendly Interface: Simplified navigation with clear visual guides, accommodating users with varying technical expertise.

- Multilingual Support: Interface available in English and Korean, catering to a broader range of users.

- Compatibility Across Various Equipment: Designed to work with a range of DOOSAN machinery, providing versatility in application.

- Regular Updates: Frequent software enhancements ensure the tool remains aligned with the latest technological advancements.

File Size and Installation Requirements

The DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 has a manageable file size of 10.5 MB and requires approximately 20 MB of space when installed on a system. The software is compatible with Windows 10 (64 bits) and Windows 11 (64 bits), ensuring users can utilize the tool effectively on modern operating systems. In addition, the installation process is straightforward, requiring minimal technical expertise and completing in a short duration.

License and Usage Time Unlimited

This software features an unlimited time license, allowing users to benefit from its diagnostic capabilities without the constraints of a time-limited trial. This aspect is particularly advantageous for companies that rely on continuous monitoring and maintenance of their machinery. The unrestricted usage ensures long-term value and support for ongoing operational needs.

The diagnostic capabilities of the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 elevate maintenance operations by enabling precise evaluations and timely interventions. This functionality is crucial for sustaining the performance of heavy machinery across various applications.

Diagnostic Capabilities

Advanced Diagnostic Features

This software is equipped with state-of-the-art diagnostic tools that empower technicians to delve deep into the inner workings of heavy equipment. These features include:

- Comprehensive error code analysis, allowing users to troubleshoot efficiently.

- Automatic updates to diagnostic algorithms, ensuring that the software adapts to new machinery and potential issues.

- Integration with historical performance data for trend analysis and anomaly detection.

Real-Time Problem Identification

Timely interventions can significantly reduce downtime. By facilitating real-time problem identification, this software allows users to:

- Monitor various parameters constantly, ensuring any deviations are promptly flagged.

- Receive alerts for critical failures, enabling immediate action to be taken.

- Utilize visual diagnostics to enhance understanding and communication of issues among team members.

Electronic System Monitoring

The capability to monitor electronic systems is vital for maintaining operational efficiency. Key monitoring features include:

Engine Diagnostics

Engine diagnostics is vital for understanding equipment performance. The software provides:

- Detailed readings of engine performance metrics, such as temperature, pressure, and RPM.

- Identification of engine faults through advanced predictive analytics.

- Guidance for preventative maintenance based on engine health indicators.

System Windows Compatibility

Ensuring compatibility with operating systems is crucial for smooth operation. This software is designed to work seamlessly with:

- Windows 10 (64 bits)

- Windows 11 (64 bits)

- Future Windows updates to maintain relevance with the latest technological advancements.

Performance Monitoring

Performance monitoring is essential for maintaining the efficiency and longevity of heavy machinery. Through the use of advanced tools and techniques, operators can keep their equipment in optimal condition and anticipate potential issues before they escalate.

Monitoring Tools

Effective performance monitoring relies on a variety of tools that collect and analyze data from machinery. These tools are designed to provide real-time insights into equipment functionality, ensuring that operators can make informed decisions about maintenance and usage.

- Telemetry Systems: Provide live data feedback from vehicles, allowing for immediate assessment of performance metrics.

- Diagnostic Interfaces: Enable operators to access a wealth of information about the health of the machinery, including error codes and system statuses.

- Mobile Applications: Offer convenient access to performance data, enabling operators to monitor equipment remotely.

Data Collection and Analysis

Data collection is a fundamental aspect of performance monitoring. The effectiveness of the machinery depends on gathering accurate information regarding its operations. This data serves as the basis for analyzing trends and making proactive maintenance decisions.

- Performance Metrics: Key performance indicators (KPIs) such as fuel consumption, engine temperature, and load capacity are continuously tracked.

- Historical Data Comparison: Analyzing historical performance allows operators to detect anomalies and implement corrective actions swiftly.

- Data Visualization: Graphs and dashboards help convey complex data in an easily understandable format, aiding in decision-making processes.

Predictive Maintenance

Predictive maintenance is a strategy that leverages data analysis to foresee equipment failures and schedule maintenance accordingly. This preemptive approach minimizes downtime and extends the lifespan of machinery.

- Condition Monitoring: Regularly assessing key components helps identify wear and tear before it becomes critical.

- Alert Systems: Automated alerts inform operators when certain thresholds are met, prompting timely maintenance actions.

- Maintenance Scheduling: Data-driven insights assist in planning maintenance activities around usage patterns, improving workflow and productivity.

User Interface and Accessibility

The User Interface and Accessibility of diagnostic software play a crucial role in user experience and effectiveness. A well-designed interface ensures that operators and technicians can navigate the program with ease, improving productivity and reducing errors during operation.

Interface Language Options

English Language Interface

The English language interface provides users with clear, concise navigation and instructions. All menus, buttons, and diagnostic messages are designed to be straightforward, making it easy for users to find the functionalities they need. This design consideration caters to a broad audience and aligns with the needs of global users in the construction and heavy machinery sectors.

Korean Language Interface

For users who speak Korean, the availability of a Korean language interface enhances accessibility. This choice allows technicians and operators from regions where Korean is predominantly spoken, to work comfortably without language barriers. Each function retains clarity and usability, ensuring that language differences do not hinder operational efficiency.

User-Friendly Design

The user-friendly design is a hallmark of effective diagnostic software. Intuitive layouts, logical navigation paths, and responsive controls contribute to a seamless experience. The software’s dashboard provides summarized information at a glance, highlighting key metrics and alerts. This focus on usability helps new users acclimate faster and supports experienced users in quickly executing tasks.

Accessibility Across All Regions

Accessibility is vital for users operating in various regions. This software is designed to function without geographical limitations. Installation and interface options cater to users worldwide, ensuring that regardless of location, technicians can utilize it efficiently. The software accommodates different internet connectivity scenarios, allowing for updates and support even in less urbanized areas.

Compatibility and versatility are crucial features for any diagnostic software, ensuring that it can operate seamlessly across various platforms and equipment types. This section explores the supported operating systems and the wide range of machinery with which the software can effectively function.

Compatibility and Versatility

Supported Platforms and OS

The DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 [2023.06] software offers robust compatibility across popular operating systems, particularly Windows. This adaptability allows for widespread application in both field and service settings.

Windows 10 (64 bits) Compatibility

This version of the software is fully compatible with 64-bit systems running Windows 10. Users can expect high performance, stability, and a user-friendly interface on this platform. The installation process is straightforward, enabling fast deployment and efficient diagnostic operations in various environments.

Windows 11 (64 bits) Compatibility

The software is also optimized for Windows 11 (64 bits). Its features are designed to take full advantage of the updated architecture of this operating system, ensuring users benefit from improved processing speeds and enhanced security. This compatibility guarantees that tech-savvy operators can efficiently utilize the software on the latest machines.

Compatibility with Various Equipment Types

This diagnostic tool is engineered for versatility, meaning it is applicable to a wide array of equipment types beyond just trucks. Its broad compatibility covers various machinery, making it an invaluable asset in multiple industrial sectors.

- Heavy-duty trucks

- Excavators

- Bulldozers

- Loaders

- Other DOOSAN branded machinery

Such a wide spectrum of compatibility ensures that technicians and operators can rely on this software for effective maintenance and issue resolution across their entire fleet. Whether it’s diagnosing engine performance or troubleshooting hydraulic systems, the software streamlines the diagnostic process for diverse equipment.

Remote Installation Support offers users the opportunity to install the software efficiently from a distance, ensuring that they can set it up without the need for an on-site technician. This process is streamlined with the help of software tools like TeamViewer.

Remote Installation Support

TeamViewer Support Options

TeamViewer is a widely recognized remote access software that facilitates the installation of DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7. It provides several advantages for both users and technicians:

- Secure connection established through encryption, ensuring data integrity.

- Real-time assistance during the installation process, allowing for immediate troubleshooting.

- Access to the user’s device from any location, making it convenient for remote locations.

- Cross-platform compatibility, enabling seamless interactions across different operating systems.

Installation Procedures

The installation of the software is designed to be user-friendly and efficient. Following a few simple steps can help ensure a smooth setup:

- Initiate a session through TeamViewer, allowing the technician to connect to the user’s computer.

- Download the installation file for DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 from a secure location.

- Execute the installation file, which guide users through the necessary setup steps.

- Complete the installation by verifying that all components are correctly installed and configured.

Post-installation, technicians can perform checks to confirm functionality and compatibility with the existing systems.

Troubleshooting and Assistance

Issues can occasionally arise during installation or operation. Fortunately, support is available to address these challenges effectively:

- Common problems such as software conflicts can often be diagnosed remotely by technicians.

- Step-by-step guides can be provided to troubleshoot issues without the need for face-to-face support.

- Regular updates and tips for maintaining optimal software performance are shared with users during sessions.

- An extensive FAQ can assist users in finding solutions to frequent questions quickly.

Remote support ensures that users receive prompt responses to their inquiries, enabling them to make the most out of the diagnostic tools available to them.

Market Analysis

The heavy machinery industry is continuously evolving, driven by advancements in technology and the increasing need for efficiency. Understanding market trends and demands for diagnostic software is crucial for companies aiming to maintain a competitive edge.

Market Needs for Diagnostic Software

The demand for diagnostic software in the heavy equipment sector is primarily fueled by the need for efficient maintenance and operational reliability. Key market needs include:

- Real-time diagnostics to minimize downtime.

- Comprehensive performance monitoring to enhance productivity.

- User-friendly interfaces that accommodate operators of varying technical expertise.

- Integration capabilities with existing machinery and systems.

- Support for multiple languages to cater to diverse user bases.

As machinery becomes increasingly sophisticated, operators require intuitive tools that can seamlessly identify issues and provide actionable insights. This trend highlights the critical role diagnostic software plays in today’s heavy machinery operations.

Competitiveness in the Heavy Equipment Sector

The heavy equipment market is characterized by intense competition among manufacturers and software developers. Companies are vying for leadership in technological innovations that enhance machinery efficiency and reliability. Key factors influencing competitiveness include:

- Product reliability and effectiveness in real-world applications.

- Brand reputation and customer loyalty.

- Pricing strategies that align with customer expectations.

- Continuous updates and customer support to maintain product relevance.

Given these factors, companies must not only offer robust software solutions but also demonstrate a commitment to customer service and ongoing product improvements.

Comparison with ECMTrucks.com

In the competitive landscape, ECMTrucks.com stands as a notable player offering diagnostic solutions tailored for heavy machinery. Their product portfolio emphasizes user experience and technical support. Comparatively, advantages may include:

- Established customer base and market presence.

- Comprehensive support and training options for users.

- Innovative features that may be more aligned with current industry needs.

This comparison highlights the importance of adaptability and understanding customer requirements in developing competitive advantage.

Competitive Advantages

Key competitive advantages for effective diagnostic software in the heavy machinery sector include:

- Superior diagnostic capabilities that provide in-depth analysis.

- Compatibility with a wide range of equipment, enhancing versatility.

- Ongoing software updates that ensure alignment with technological advancements and regulatory changes.

- Strong customer feedback mechanisms for continuous improvement.

Companies that can leverage these advantages are better positioned to meet the evolving demands of the market and to establish a strong foothold in the industry.

Customer reviews and feedback are crucial for understanding user experiences and enhancing the product. This section analyzes the way users perceive the software and its impact on operational efficiency.

Customer Reviews and Feedback

Gathering User Feedback

The process of gathering user feedback involves multiple channels. Companies often employ surveys, direct interviews, and online reviews to capture the sentiments of users effectively. This feedback is invaluable as it provides insights into how the software performs in real-world applications.

- Surveys: Targeted surveys can be distributed to existing users, capturing both quantitative and qualitative data regarding satisfaction levels.

- Interviews: Conducting structured interviews with a sample of users can yield in-depth insights into user experiences and areas for improvement.

- Online Reviews: Monitoring user reviews on platforms dedicated to software insights can reveal prevailing trends and common issues faced by users.

Feedback collected through these methods allows for continuous improvement and adaptation to meet user needs. It serves as a touchpoint for companies to identify strengths and address weaknesses in their software offerings.

Importance of Legitimate Reviews

Legitimate reviews play a significant role in the credibility and decision-making process for prospective buyers. Authentic feedback builds trust and enables informed choices backed by real experiences from existing users. Some key reasons why legitimate reviews are essential include:

- Trustworthiness: Genuine reviews contribute to transparency, assuring potential buyers of the product’s reliability.

- Guidance: Constructive criticism helps potential customers understand what to expect and how the software can cater to their specific needs.

- Improvement: User feedback often highlights areas needing attention, guiding developers in refining the software to enhance user satisfaction.

Gathering and promoting legitimate reviews creates a cycle of trust and accountability. Companies that prioritize user feedback cultivate a loyal customer base and ensure ongoing engagement with their products.

Related Products

In the market for heavy machinery diagnostic tools, there are several products that complement and enhance operational efficiency. The following related products provide varied functionalities tailored to specific equipment needs.

NEW HOLLAND CONSTRUCTION NORTH AMERICA EPC

The New Holland Construction North America EPC (Electronic Parts Catalog) software serves as a vital resource for professionals working with New Holland machinery. This product is engineered to assist in the efficient identification and ordering of parts, ensuring that operators can maintain their equipment with minimal downtime.

- Provides detailed parts diagrams and descriptions

- Facilitates the quick lookup of parts and accessories

- Compatible with various New Holland models

- Seamlessly integrates with inventory management systems

With its user-friendly interface, this software allows technicians to pinpoint specific components efficiently. It also contributes significantly to managing maintenance schedules and ensuring that the right parts are available when needed.

BOBCAT ENGINE ANALYZER DCU

The Bobcat Engine Analyzer DCU (Diagnostic Control Unit) is designed specifically for Bobcat equipment. It is focused on delivering high-precision diagnostics and performance monitoring for engines.

- Advanced diagnostic capabilities for engine management systems

- Real-time data collection for precise performance analysis

- Support for multiple Bobcat models

- User-friendly application for both seasoned and novice technicians

This diagnostic tool empowers users with insights that can lead to proactive maintenance decisions. The ability to diagnose problems early ensures reduced operational costs and increased equipment longevity.

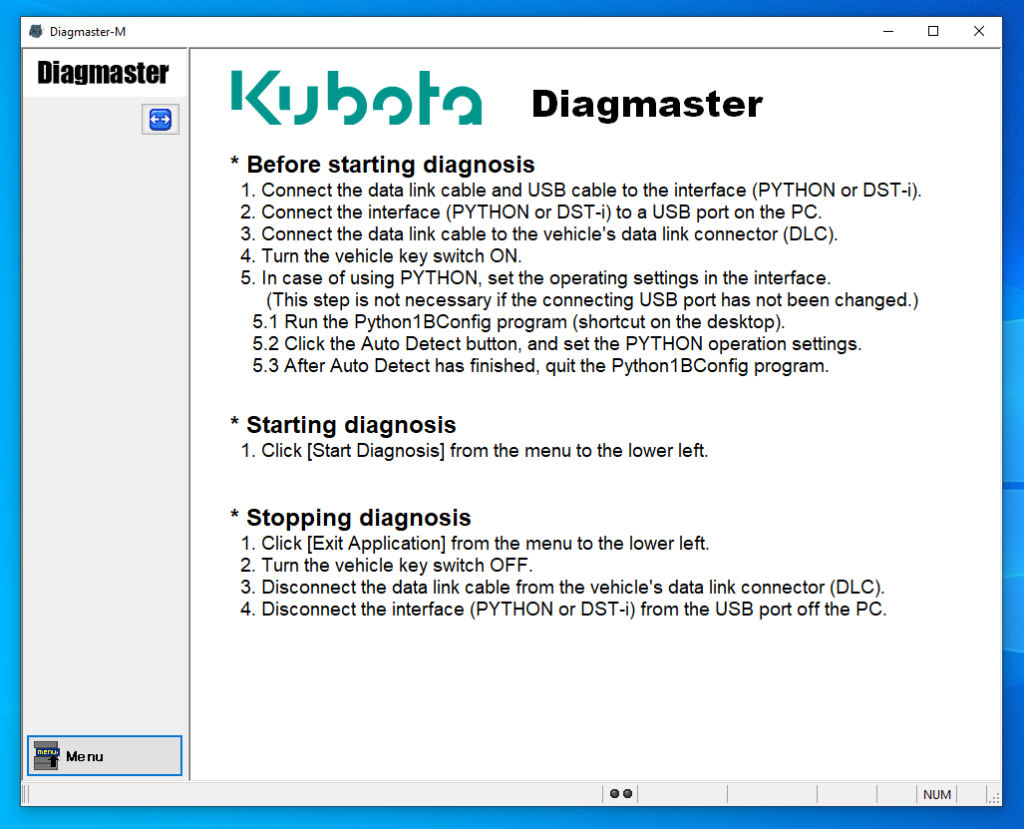

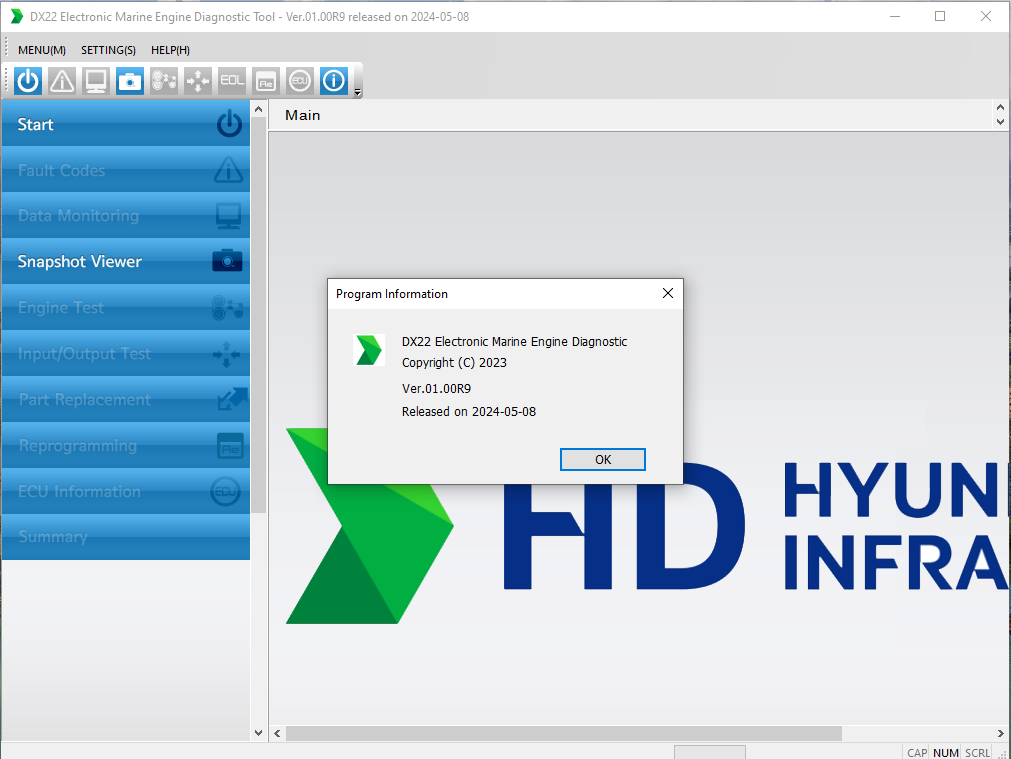

DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ENGINE ANALYZER

The DX22 Electronic Marine Engine Analyzer is tailored for marine applications, providing essential diagnostic support for electronic systems in marine engines. While its focus is on watercraft, the principles of diagnostics can be insightful for heavy machinery operators.

- Comprehensive diagnostics for marine engine electronics

- Logging of performance data for trend analysis

- Multi-language support for user accessibility

- Robust design suitable for harsh marine environments

This diagnostic tool showcases how advanced technology can enhance maintenance and operational awareness, reflecting the increasing demand for such solutions across various sectors, including land and marine applications.

The Technical Specifications section provides essential details regarding the software’s capabilities, including its type, file size, installation footprint, and compatibility with operating systems. This information is crucial for users to ensure proper installation and optimal performance.

Technical Specifications

Software Type: Diagnostic Tool

This software is classified as a diagnostic tool specifically tailored for heavy machinery. It provides advanced functionalities designed for effective monitoring and troubleshooting of DOOSAN equipment. The tool’s primary purpose is to streamline the diagnostic process, allowing technicians to quickly identify and analyze issues that may arise in the machinery’s operation.

File Size and Installation Footprint

The file size for the DOOSAN EDIA TRUCK SUPERVISOR software is 10.5 MB, which ensures a quick download experience. Once installed, the software occupies approximately 20 MB of disk space. This compact size allows for easy installation and minimal impact on system resources, making it suitable for various environments, especially in settings with limited storage capacity.

Operating System Requirements

To ensure optimal performance, specific operating system requirements need to be met:

- Compatible with Windows 10 (64 bits)

- Compatible with Windows 11 (64 bits)

These compatibility options ensure that users can effectively run the software on their preferred platforms without encountering significant issues. The software is designed to leverage the advances in these operating systems, offering a stable and efficient environment for diagnostic tasks.

Database and Languages

The Database and Languages section highlights the linguistic adaptability of the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 [2023.06] software, emphasizing its database structuring and interface language options. These features enhance user interaction and accessibility across diverse user demographics.

Database Language: English

The primary database language for the DOOSAN EDIA TRUCK SUPERVISOR is English. This facilitates a broad understanding and usability among the majority of users within the industry. The use of English empowers operators and technicians to effectively interpret diagnostic information, enhancing their ability to address issues promptly.

Having English as the database language ensures that vital information is readily accessible, allowing for seamless navigation and interpretation of data logs, fault codes, and system alerts. This uniformity in language supports a standardized approach towards diagnostics, making troubleshooting more efficient.

Interface Language: English and Korean

The software interface supports both English and Korean languages, catering to a wider audience and providing essential flexibility. This bilingual support is particularly beneficial for users operating in regions where Korean is predominant, thus bridging communication gaps within diverse teams.

English Language Interface

The English language interface is designed to be intuitive and user-friendly, ensuring that operators from various technical backgrounds can effectively navigate the software. All menus, prompts, and diagnostic results are clearly displayed in English, facilitating a straightforward experience for users.

Korean Language Interface

The Korean language interface offers a localized experience, enabling users to interact with the software in their native language. This feature enhances comfort and proficiency, particularly for technicians and operators who may prefer or require Korean to operate efficiently.

By providing both English and Korean interfaces, the software demonstrates its commitment to inclusivity and user-friendliness, ultimately contributing to improved operational efficiency across different markets.

Diagnostic Software for Different Brands

As heavy machinery continues to evolve, the demand for specialized diagnostic software tailored to various brands becomes increasingly critical. This section explores the diagnostic solutions available for two prominent manufacturers, DOOSAN and NEW HOLLAND, highlighting their unique functionalities and advantages.

DOOSAN Heavy Equipment

DOOSAN’s diagnostic software is designed specifically for its range of heavy machinery, ensuring comprehensive support for maintenance and performance monitoring. This software provides a host of features that help operators and technicians effectively manage their equipment.

- Comprehensive Diagnostics: The software allows users to perform thorough diagnostics, facilitating quick identification of issues within DOOSAN machinery.

- Performance Tracking: Operators can monitor operational efficiency, which helps in optimizing equipment use and reducing downtime.

- User-Friendly Interface: The design prioritizes ease of use, allowing users of varying skill levels to navigate and utilize the software effectively.

- Compatibility with Multiple Models: The software supports a wide range of DOOSAN equipment, including excavators, loaders, and trucks, ensuring versatility across the fleet.

- Regular Updates: DOOSAN continually enhances its software offerings, providing updates that incorporate the latest technological advancements and industry best practices.

NEW HOLLAND Heavy Equipment

Like DOOSAN, NEW HOLLAND offers specialized diagnostic software tailored to its heavy machinery. This software integrates advanced technology to ensure optimal performance and maintenance of all equipment types.

- Advanced Diagnostic Tools: NEW HOLLAND’s software provides in-depth diagnostic capabilities, allowing users to troubleshoot problems and enhance machine longevity.

- Data Analysis Features: Users can collect and analyze data on equipment performance, helping them make informed decisions regarding maintenance and operation strategies.

- Multilingual Support: The interface accommodates users across different regions by offering multiple language options, promoting accessibility.

- Compatibility Across Models: The software supports a variety of NEW HOLLAND machinery, including tractors, excavators, and compactors, catering to diverse operational needs.

- Seamless Integration: The diagnostic tool can be integrated with existing systems, providing operators with a cohesive operational experience.

Privacy Policy and Terms

This section outlines the Privacy Policy and Terms that govern the use of the software, ensuring users understand their rights and the handling of their information.

Privacy Policy Overview

The Privacy Policy describes the types of information that is collected when using the software and how that information is used, protected, and shared. Understanding this policy is crucial for users to safeguard their personal data and make informed choices.

- Information Collection: The software may collect personal information including, but not limited to, name, contact details, and usage data.

- Data Usage: Collected data is primarily used to enhance user experience, improve functionality, and inform users about updates and features.

- Data Protection: Measures are in place to protect user information from unauthorized access and misuse.

- Information Sharing: User data may be shared with third parties only under circumstances that ensure user privacy is maintained, such as necessary legal obligations.

Terms of Service and Use

The Terms of Service detail the rules and regulations governing the use of the software. By using the software, users agree to abide by these terms.

- License Grant: Users are granted a non-exclusive, unlimited license to use the software under the defined terms.

- Restrictions: Users must not reproduce, modify, or distribute the software without prior written consent.

- Limitation of Liability: The software provider is not liable for any indirect, incidental, or consequential damages resulting from the use of the software.

- Governing Law: The terms shall be governed by and construed in accordance with the laws of the jurisdiction where the software provider is established.

FAQ Section

This section addresses common inquiries regarding installation, troubleshooting, and licensing for the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 [2023.06]. It aims to provide clarity and support for potential users.

Common Questions About Installation

Users often have several questions related to the installation process of the software. Here are some frequently asked questions:

- What are the system requirements for installation?The software requires a computer running Windows 10 (64 bits) or Windows 11 (64 bits). Ensure that your operating system is up to date for optimal performance.

- How is the installation process conducted?The installation is straightforward. After downloading the software, simply follow the on-screen prompts. Make sure to grant necessary permissions during installation.

- Can I install the software on multiple devices?Installation on multiple devices requires separate licenses. Each installation must be registered with its respective license key.

- Is remote installation support available?Yes, support for remote installation through TeamViewer is offered. This ensures users receive assistance during setup, streamlining the process.

Troubleshooting Common Issues

Issues may arise during or after installation. Below are typical questions regarding troubleshooting:

- What should I do if the installation fails?If the installation fails, restart your computer and try again. Ensure that your system meets all requirements and that no other installations are in progress.

- How can I resolve compatibility issues?Check for any pending updates for your operating system. If issues persist, consult the installation guide for specific compatibility resolutions.

- What if the software does not launch?Ensure that your antivirus is not blocking the application. Additionally, check your task manager to see if the software is running in the background and restart if necessary.

- Where can I find support for other technical issues?Technical support can be accessed via the software’s support page, which may include FAQs, user forums, and contact options for additional help.

Understanding License Time Unlimited

The licensing model for the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 offers unlimited usage, presenting several queries regarding its terms:

- What does time unlimited mean for users?This means that once the software is purchased, users can utilize it indefinitely without worrying about subscription fees or renewal requirements.

- Are there any limitations to the unlimited license?While the license is unlimited, it is tied to the specific device where the software is installed. Transferring the license may require a reactivation process.

- Can the license be used for commercial purposes?Yes, the license allows for commercial use, making it suitable for businesses that operate heavy machinery within the industry.

- If I upgrade my computer, can I transfer my license?License transfer is possible, but it may involve contacting support for guidance on reactivation. It is advisable to have your purchase information available when requesting assistance.

Support and Updates

Efficient and reliable support, as well as regular updates, are crucial elements for maintaining the effectiveness and performance of software dedicated to heavy machinery diagnostics.

Regular Software Updates

Regular updates to the DOOSAN EDIA TRUCK SUPERVISOR 2.4.0.7 software are essential to ensure optimal performance and compatibility with the latest technologies. These updates include enhancements that improve system functionality, user experience, and diagnostic accuracy. Frequent updates are designed to address bugs, integrate user feedback, and adapt to evolving industry standards.

- Software improvements that enhance usability

- Integration of new diagnostic features

- Compatibility adjustments for new equipment models

- Security enhancements to protect user data and software integrity

Updating the software is straightforward, typically requiring a simple download and installation process. Users are encouraged to keep their systems up to date for a seamless experience and to take advantage of the latest functionalities.

Remote Support Services

Access to remote support services strengthens the operational capabilities of the DOOSAN EDIA TRUCK SUPERVISOR software. This feature allows users to receive assistance from technical experts regardless of their location. Through remote support, issues can be resolved promptly, minimizing downtime and maintaining productivity.

- Real-time troubleshooting and diagnostics available via online tools

- Assistance with installation and configuration to ensure optimal setup

- Guided support using tools like TeamViewer for direct resolution of user issues

These services not only provide immediate guidance but also create a sense of confidence among users knowing that help is readily available. Regular interaction with support teams can lead to deeper insights into the software’s capabilities and help users maximize efficiency.

Purchasing Details provide essential information regarding the acquisition of this diagnostic software, ensuring users understand their options and can make informed decisions.

Purchasing Details

How to Buy

The process for purchasing the software is straightforward. Interested parties can visit the ecmtrucks.com website, where they will find the dedicated section for DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06]. A user-friendly interface guides customers through the purchasing steps.

Users can complete the purchase by following these steps:

- Select the desired software version.

- Add the software to the shopping cart.

- Provide necessary information during checkout.

- Confirm payment through secure methods offered on the site.

Upon successful transaction, users receive confirmation emails, which include download instructions and licensing details.

Licensing Options and Costs

The software is available under a time-unlimited license, delivering ongoing value without the need for recurring fees. This option is designed to benefit both individual operators and larger enterprises relying on heavy machinery.

Licensing details are as follows:

- Single-User License: Ideal for individual users who require full access to the software’s features and capabilities.

- Multi-User License: Designed for organizations with multiple users, offering a cost-effective solution to provide access across teams.

- Enterprise License: Tailored for large organizations, this option includes additional benefits such as priority support and exclusive updates.

The pricing structure varies based on the license type, but is competitively set to accommodate different budgets while ensuring the software remains accessible. To ensure users stay up-to-date, regular updates are included as part of the purchase.

Software Maintenance

Maintaining software effectively ensures optimal functionality and extends its lifespan. Regular maintenance involves systematic checks and updates to keep the software running smoothly and to prevent potential issues that may arise over time.

Regular Maintenance Tips

Implementing routine maintenance practices is essential for maximizing performance. Below are several recommended tips:

- Schedule regular software updates to enhance features and security measures.

- Perform periodic backups of critical data to prevent loss due to unforeseen circumstances.

- Clear temporary files and caches regularly to improve application speed and efficiency.

- Monitor system resources to ensure optimal performance and address any bottlenecks quickly.

- Review and manage user permissions to maintain security and functionality.

Best Practices for Using the Software

Adopting best practices helps in utilizing the software effectively while reducing the chances of errors. Organizations should consider the following:

- Train users thoroughly on the software to maximize its capabilities and ensure they are aware of updates and features.

- Document all processes and changes made within the software for future reference and compliance.

- Encourage regular feedback from users to identify any recurring issues or areas needing improvement.

- Establish a clear communication channel for reporting problems or seeking assistance to streamline support processes.

- Utilize the remote installation features when needed, allowing for better support and problem resolution without physical presence.

Software Performance

Software performance is critical in evaluating how effectively a program operates. For diagnostic software designed for heavy machinery, efficiency can dramatically influence operational productivity and maintenance workflows. Analyzing performance through various metrics ensures that the software meets the demands of users.

Measuring Software Efficiency

Measuring the efficiency of diagnostic software involves several key performance indicators (KPIs) that reflect its reliability and effectiveness in real-world applications. The following factors are considered when analyzing software efficiency:

- Response Time: The speed at which the software processes diagnostic queries and returns results is paramount. Faster response times lead to less downtime and improved service quality.

- Accuracy: High accuracy in diagnosing issues ensures that operators can trust the software’s outputs, leading to better decision-making regarding maintenance and repairs.

- Resource Utilization: Efficient software should require minimal system resources while maximizing functionality. This ensures compatibility with various equipment and operational settings.

- User Satisfaction: Gathering feedback from users provides insights into the ease of use and effectiveness of the software. Positive user experiences are crucial for long-term adoption and trust in the system.

Regular monitoring of these KPIs helps in understanding the operational landscape of the software, leading to timely updates and improvements that align with user needs and industry standards.

Case Studies on Application

Real-world application of diagnostic software often illustrates its impact on operational efficiency and maintenance planning. Here are a few examples highlighting the effectiveness of the software in different scenarios:

- Construction Fleet Management: A construction company utilizing the software reported a 30% reduction in equipment downtime. By employing predictive maintenance features, the team could address issues before they escalated, enhancing overall productivity.

- Mining Operations: A mining operation implemented the software to monitor their heavy machinery and achieved significant operational cost savings. The precise diagnostics allowed for targeted repairs, which minimized unnecessary parts replacements and labor costs.

- Agricultural Equipment Maintenance: Farms using the diagnostic tool for their agricultural machinery noted improved equipment reliability. Users could track performance data effectively, which facilitated informed maintenance schedules and ultimately boosted harvest efficiency.

These case studies demonstrate the tangible benefits of integrating advanced diagnostic tools into operational routines, allowing businesses to thrive in competitive industries through effective machine monitoring and maintenance strategies.

Advanced Features

The advanced features of the software encompass a variety of customization options and integration capabilities that enhance its functionality and adaptability within different operational frameworks.

Customization Options

The software offers a range of customization options that allow users to tailor the application to meet specific operational requirements. This flexibility is crucial for organizations that rely on unique workflows and processes.

- User Profiles: The ability to create user profiles enables different team members to access features relevant to their roles. Users can configure settings such as language preferences, diagnostic tools, and performance metrics that are crucial for their specific applications.

- Report Generation: Customized reporting features permit users to generate detailed reports based on the data collected. Users can define parameters for analysis, ensuring that reports meet their specific needs for monitoring performance or diagnosing issues.

- Interface Modifications: Users can adjust the interface layout according to their preferences, enhancing usability and ensuring that key information is readily accessible.

Integrating with Existing Systems

The ability to integrate the software with existing systems is a critical advantage, allowing it to work seamlessly within an organization’s technological ecosystem. This compatibility fosters efficient operations and maximizes the effectiveness of both old and new systems.

- API Access: The software includes robust API access that enables integration with a variety of third-party applications. Companies can connect their existing software solutions for inventory management, fleet tracking, and maintenance scheduling, ensuring a cohesive operational flow.

- Data Synchronization: Users can synchronize data across platforms, maintaining updated information across systems. This feature minimizes data discrepancies and strengthens overall operational efficiency.

- Legacy System Compatibility: The software is designed to work with many legacy systems. This capability allows organizations to gradually transition to newer technologies without sacrificing functionality.

Ensuring Compliance

Ensuring compliance is essential for organizations utilizing diagnostic software, particularly in industries with strict regulations. Adhering to both regulatory requirements and industry standards is vital for maintaining operational integrity and ensuring safety.

Regulatory Compliance

Regulatory compliance refers to the adherence to laws, regulations, guidelines, and specifications that are relevant to business processes. Organizations must stay updated with local, state, and federal regulations that govern the operation of heavy machinery and diagnostic tools. These regulations aim to ensure safety, environmental protection, and operational efficiency.

Key areas of regulatory compliance include:

- Environmental Regulations: Guidelines that restrict harmful emissions and promote sustainable practices in heavy machinery operations.

- Occupational Safety: Compliance with standards that ensure the safety and health of workers operating heavy equipment.

- Data Protection: Adhering to laws related to the security and privacy of user data collected through diagnostic software.

To remain compliant, organizations often conduct periodic audits and updates to their processes, ensuring that they meet all necessary regulatory requirements.

Industry Standards

Industry standards provide a framework for best practices and operational benchmarks across various sectors. Compliance with these standards enhances reliability, safety, and performance in the use of diagnostic tools for heavy machinery.

Common industry standards include:

- ISO 9001: A standard for quality management systems ensuring consistent quality in products and services.

- OSHA Standards: Regulations set forth by the Occupational Safety and Health Administration to promote safe and healthful working conditions.

- EPA Guidelines: Standards established by the Environmental Protection Agency focusing on environmental health and safety regulations.

Meeting these industry standards not only ensures compliance but also establishes a company’s credibility in the market. Adhering to such standards can lead to greater efficiency, reduced risk of accidents, and improved customer satisfaction.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

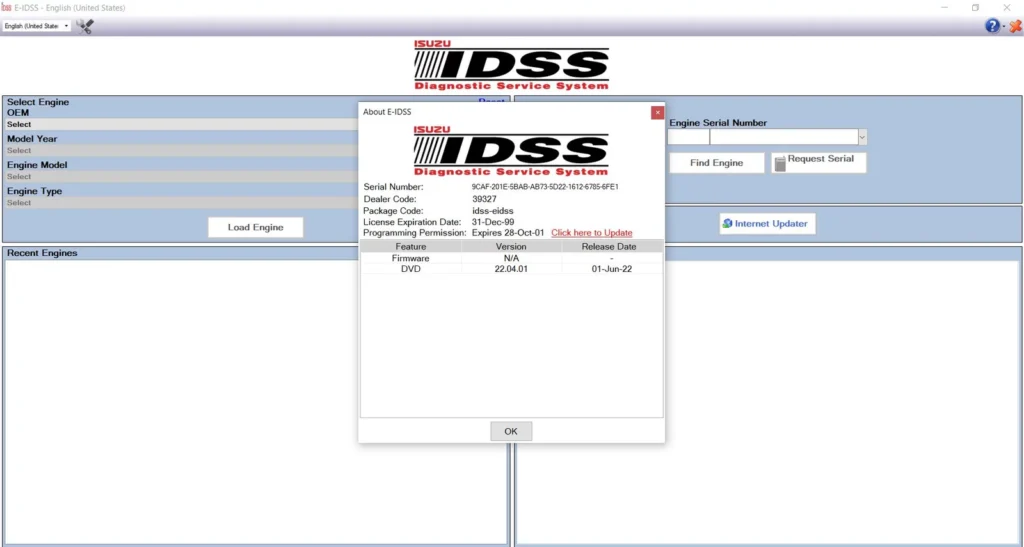

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR![The DOOSAN EDIA TRUCK STANDART 2.4.0.7 [2023.06] , released in 2023, is a vital tool for diagnosing and maintaining heavy machinery. It offers advanced features crucial for optimizing operational efficiency and minimizing downtime. This software is designed to support various systems and provides real-time diagnostics for multiple types of equipment. Additionally, it includes remote installation support via TeamViewer to ensure a smooth setup process.](https://ecmtrucks.com/wp-content/uploads/2024/08/4455-600x600.png)

![The DOOSAN EDOCTOR CONSTRUCTION FULL 2.3.5.8 [2023.06] is a cutting-edge diagnostic software for heavy machinery. Released in 2023, it offers advanced tools for troubleshooting engine issues in various construction equipment. This software enhances operational efficiency by providing detailed diagnostics and real-time support. It is compatible with multiple brands and supports remote installation through TeamViewer, ensuring seamless usability for technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/88-600x600.png)

![DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06] is a vital diagnostic software designed for heavy machinery. It provides users with tools for efficient maintenance and monitoring of DOOSAN trucks and equipment. This software simplifies problem identification and performance tracking. It also offers support for remote installations using TeamViewer, making it accessible and user-friendly for operators and technicians. DOOSAN EDIA TRUCK SUPERVISER 2.4.0.7 [2023.06] is a vital diagnostic software designed for heavy machinery. It provides users with tools for efficient maintenance and monitoring of DOOSAN trucks and equipment. This software simplifies problem identification and performance tracking. It also offers support for remote installations using TeamViewer, making it accessible and user-friendly for operators and technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/44-1.png)

Reviews

Clear filtersThere are no reviews yet.