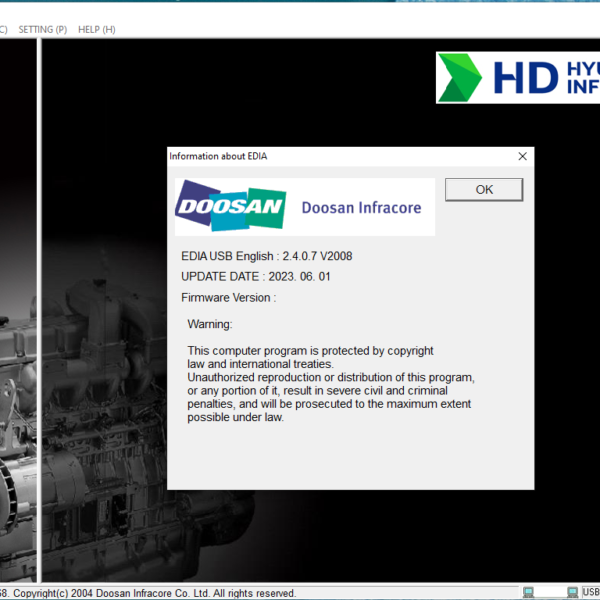

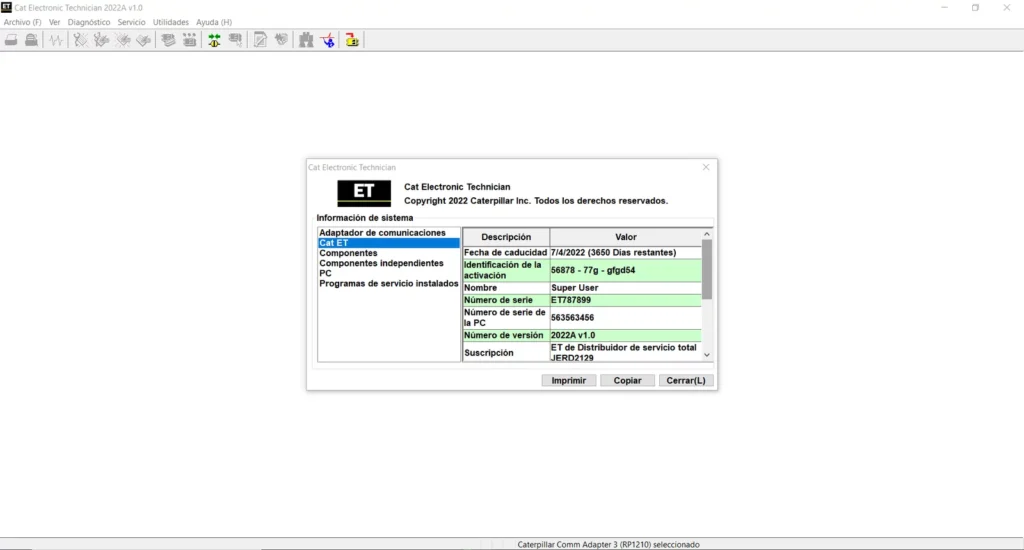

DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06] : Optimize Your Heavy Equipment Management Today!

DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06] is a comprehensive diagnostic software specifically designed for Doosan machinery. This version, released in June 2023, enhances monitoring and troubleshooting capabilities for heavy equipment. The software features an intuitive user interface and supports continuous updates. It is also compatible with various Doosan models and offers remote installation assistance via TeamViewer, maximizing efficiency in equipment management.

Understanding DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06]

This section explores the significance and capabilities of DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 in the machinery management landscape.

Overview of DOOSAN EDIA AS FULL SUPERVISOR

DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06] serves as a comprehensive diagnostic software aimed at enhancing the maintenance and operational efficiency of Doosan machinery. Its user-centric design is tailored for both technicians and operators in the heavy equipment sector.

Key Features and Functionalities

The software comes equipped with a range of functionalities that elevate its utility in the field.

Diagnostic Capabilities

With its robust diagnostic features, the software provides detailed error codes and potential solutions, enabling quick identification and resolution of issues.

Intuitive User Interface

The user-friendly interface simplifies navigation, allowing users to efficiently access key functions without extensive training.

Continuous Updates

Regular updates ensure the software remains current with the latest technological advancements and model improvements, optimizing diagnostic processes.

Compatibility with Doosan Models

Designed to work with a broad spectrum of Doosan machinery, this software adapts seamlessly to various models, enhancing its versatility.

Multilingual Support

Supporting multiple languages, the software makes it accessible for users across different regions, fostering effective communication and usability.

To ensure optimal performance of the software, meeting specific system requirements is essential. The following outlines the necessary specifications and components.

System Requirements

Recommended Operating System: Windows

The preferred operating system for running this software is Windows 7, though compatibility with more recent versions should be verified for the best user experience.

Hardware Requirements

Storage and Memory Needs

A minimum of 30 MB of free space is necessary for installation, along with an additional 19.7 MB for the software itself. Adequate RAM is also required to ensure seamless operation.

Processor Specifications

It is vital to have a processor that meets or exceeds the software’s performance needs. A multi-core processor is recommended to enhance processing speeds during diagnostics.

Necessary Interfaces and Connections

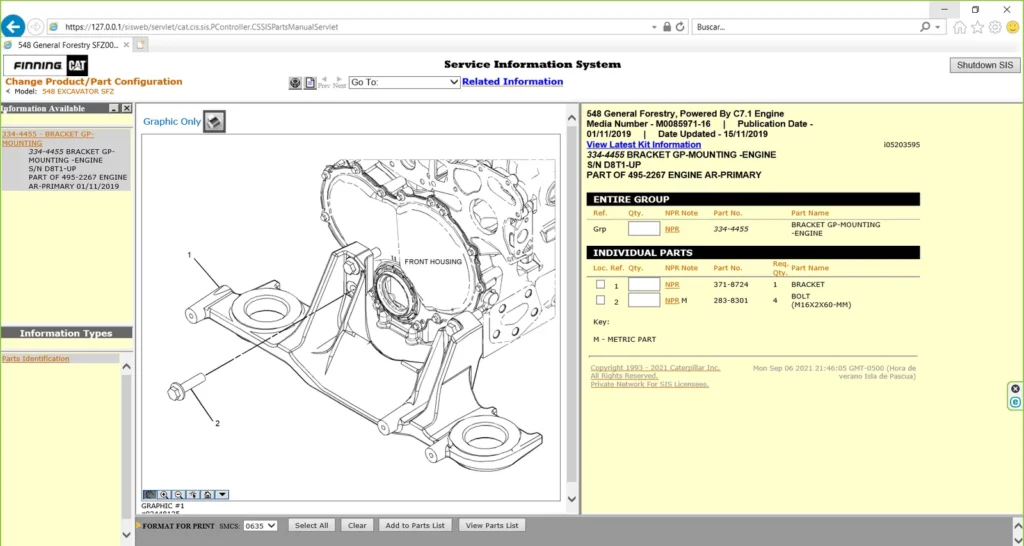

UVIM Diagnostic Kit

To connect the software with the machinery, having a UVIM diagnostic kit is essential. This allows for efficient communication and accurate diagnostics.

USB Link Compatibility

The system should include a USB port compatible with the diagnostic tools used for effective interaction between the software and the heavy equipment.

Benefits of Using DOOSAN EDIA AS FULL SUPERVISOR

The DOOSAN EDIA AS FULL SUPERVISOR offers various advantages that significantly enhance operational efficiency and cost-effectiveness in heavy machinery management.

Enhancing Diagnostic Efficiency

With its advanced diagnostic capabilities, this software identifies issues swiftly and accurately. This leads to minimized downtime and quicker resolutions for equipment malfunctions. A detailed understanding of error codes allows technicians to implement solutions effectively.

Cost Savings

Utilizing this software can lead to substantial savings for businesses. By diagnosing problems accurately, unnecessary repairs can be avoided. This not only preserves equipment integrity but also optimizes the use of spare parts and resources, resulting in lower overall operational costs.

Improved Technical Training and Skill Development

The software aids in enhancing the skill sets of technicians and operators. By working with a tool that provides comprehensible diagnostics, users gain practical experience that elevates their technical capabilities. Regular training sessions offered as part of the software package further ensure that users remain proficient and knowledgeable in its application.

Comparing to Previous Versions

Recent advancements in DOOSAN EDIA AS FULL SUPERVISOR have led to significant improvements over previous versions, enhancing user experience and functionality.

Enhanced Processing Speed

The latest version boasts a noticeable increase in processing speed. Optimized algorithms and improved resource management ensure that commands are executed more swiftly, reducing waiting times for users. This enhancement allows for quicker diagnostics and real-time responses during operations.

Additional Diagnostic Functions

With the introduction of new diagnostic features, users can perform a broader range of assessments. This includes:

- Advanced error code analysis, enabling deeper insights into machinery issues.

- Calibration adjustments directly through the software, improving equipment accuracy.

- Enhanced reporting tools that allow for comprehensive analysis of machine performance over time.

Improved Graphical Interface

The user interface has undergone a significant redesign to enhance usability. Key improvements include:

- A more intuitive layout that simplifies navigation among various functionalities.

- High-quality graphics that make data visualization clearer and more engaging.

- Customizable dashboards, allowing users to prioritize the information most relevant to their needs.

Industry Impact

The impact of advanced diagnostic software on the construction and heavy equipment sectors is profound. By enhancing operational efficiency, businesses can achieve significant gains in productivity and profitability.

Increased Equipment Uptime

Effective diagnostic tools lead to quicker identification and resolution of equipment issues. This results in:

- Reduced downtime, allowing machinery to be back in operation swiftly.

- Extended lifespan of equipment through timely maintenance and repairs.

Benefits to Construction and Heavy Equipment Management

The implementation of sophisticated diagnostic software offers multiple advantages for construction management, such as:

- Improved decision-making based on accurate data analytics.

- Streamlined maintenance schedules, which can lower operational costs.

- Enhanced safety protocols by ensuring machines are in optimal condition.

Integration with Digital Fleet Management

Modern diagnostic solutions integrate seamlessly with digital fleet management systems. Key points include:

- Real-time monitoring of equipment performance metrics.

- Facilitated data sharing across platforms, enabling coordinated operations.

- Increased strategic insights for fleet optimization and resource allocation.

Commercial Availability

The DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 is readily accessible through various purchasing options and distributors. This flexibility allows users to select the most suitable solutions for their operational needs.

Purchasing Options

There are multiple license types available for users, catering to different requirements.

-

License Types: Basic to Comprehensive Packages

Options range from basic licenses suitable for small operations to comprehensive packages designed for larger fleets. Each level provides tailored functionalities that enhance machinery management.

-

Unlocked vs. Locked Versions

Users can choose between unlocked versions, which offer enhanced flexibility, and locked versions that provide standard functionalities. This choice allows companies to select a version that best fits their operational framework.

Main Distributors

Several platforms specialize in offering this software, ensuring efficient access and support.

-

ecmtrucks.com

A primary distributor, ecmtrucks.com provides various purchasing options, along with expert assistance.

-

Other Platforms: Mecaprograms, Diagxiq

In addition to ecmtrucks.com, users can explore Mecaprograms and Diagxiq for alternatives, each offering distinct advantages and services related to the software.

Remote Installation Support via TeamViewer

Support for remote installation is available through TeamViewer, ensuring that users can set up and configure the software quickly and efficiently, maximizing operational uptime.

Support and Training

Comprehensive support and training resources are essential for users to maximize the potential of their software. Accessible assistance ensures efficient usage and problem resolution.

Technical Assistance

Users of DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 can access round-the-clock technical support. This service is valuable for troubleshooting issues and resolving any software-related queries. Technical experts are available to provide guidance, ensuring minimal disruption to operations.

Online Resources and Tutorials

A variety of online resources are available to enhance user experience. These include:

- Step-by-step video tutorials demonstrating key functions.

- FAQs addressing common issues and concerns.

- User manuals containing detailed instructions and tips.

These resources cater to different learning preferences and help users navigate the software efficiently.

Formal Training Programs

Structured training programs are offered for those seeking in-depth knowledge of the software. These programs often include:

- Hands-on workshops led by experienced instructors.

- Webinars covering advanced features and troubleshooting methods.

- Certification courses to validate user competence.

Formal training equips users with the skills necessary for effective software utilization, enhancing overall productivity.

Frequently Asked Questions (FAQs)

This section addresses some of the common inquiries regarding the software’s installation, troubleshooting, updates, and customization.

Common Installation Issues

Installation problems may arise due to a variety of factors. Common issues include:

- Incompatible operating system versions, primarily Windows-related.

- Insufficient system resources such as RAM or storage space.

- Failed connections with the necessary hardware interfaces.

Troubleshooting Diagnostic Errors

Errors during diagnosis can be frustrating. Common steps to resolve these errors involve:

- Verifying that the software is up-to-date.

- Ensuring the diagnostic equipment is properly connected.

- Resetting the software to refresh its diagnostic capabilities.

Understanding Software Updates

Regular updates are essential to maintain optimal performance. Key points include:

- Updates typically enhance diagnostic functions and fix bugs.

- Users will receive notifications for available updates.

- Frequent updates ensure compatibility with new Doosan models.

Language and Interface Customization

Customization options allow for a more user-friendly experience. Important aspects include:

- Support for multiple languages to cater to diverse users.

- Adjustable interface settings to fit user preferences.

- Tips for configuring the software according to operational needs.

Maximizing Your Investment

Maximizing the potential of this software ensures a favorable return on investment. Effective usage, regular maintenance, and optimization strategies enhance performance and longevity.

Best Practices for Software Usage

Implementing best practices can significantly enhance the efficiency of the software. Key strategies include:

- Regularly review diagnostic reports to identify patterns.

- Utilize the software’s full range of features to streamline operations.

- Engage in ongoing training to keep up with updates and new functionalities.

Long-term Maintenance and Updates

Consistent maintenance is vital for optimal software performance. Key maintenance practices include:

- Schedule periodic updates to access the latest features and fixes.

- Monitor system performance to address any issues early.

- Maintain adequate system requirements to support software efficiency.

Leveraging Full Superviser for Optimal Performance

Utilizing the software to its fullest can drive operational efficiency. Focus areas include:

- Integrating diagnostic insights into daily maintenance routines.

- Customizing settings based on specific equipment models for improved accuracy.

- Using remote support features to troubleshoot swiftly.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR![DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 [2023.06] is an essential diagnostic software designed for Doosan machinery. Released in June 2023, it enhances maintenance and troubleshooting processes for heavy equipment. This version offers improved functionality, user-friendly features, and unlimited licensing. It also provides remote installation support via TeamViewer, ensuring users can maximize their investment effectively.](https://ecmtrucks.com/wp-content/uploads/2024/08/11-600x600.png)

![DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06] is a comprehensive diagnostic software specifically designed for Doosan machinery. This version, released in June 2023, enhances monitoring and troubleshooting capabilities for heavy equipment. The software features an intuitive user interface and supports continuous updates. It is also compatible with various Doosan models and offers remote installation assistance via TeamViewer, maximizing efficiency in equipment management. DOOSAN EDIA AS FULL SUPERVISOR 2.4.0.7 [2023.06] is a comprehensive diagnostic software specifically designed for Doosan machinery. This version, released in June 2023, enhances monitoring and troubleshooting capabilities for heavy equipment. The software features an intuitive user interface and supports continuous updates. It is also compatible with various Doosan models and offers remote installation assistance via TeamViewer, maximizing efficiency in equipment management.](https://ecmtrucks.com/wp-content/uploads/2024/08/55.png)

Reviews

Clear filtersThere are no reviews yet.