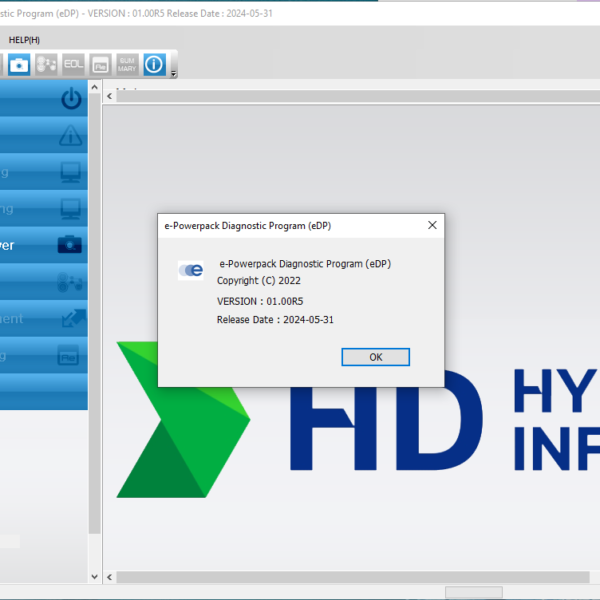

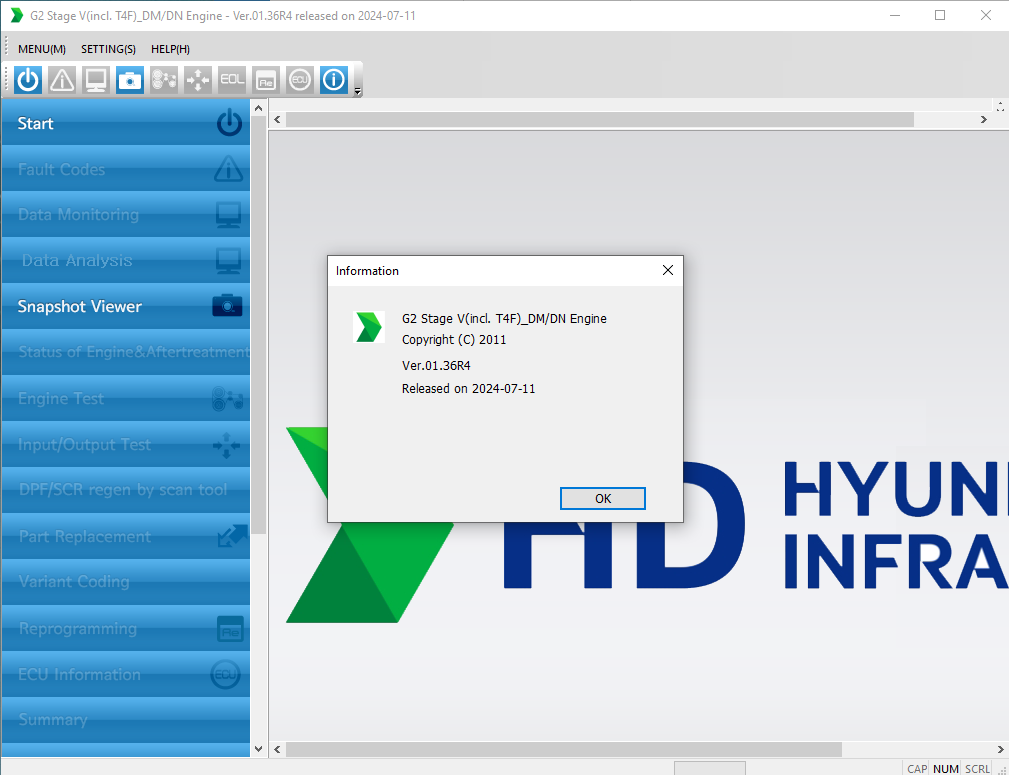

DOOSAN DIAGNOSTIC TOOL G2 Stage V(incl. T4F) 01.36 R4 2024: Optimize Your Heavy Machinery Now!

The DOOSAN DIAGNOSTIC TOOL G2 Stage V(incl. T4F) 01.36 R4 2024 , is an essential software solution for heavy machinery maintenance. It offers advanced diagnostic capabilities that enhance equipment performance and reliability. This tool supports various DOOSAN machinery and ensures compliance with current environmental standards. Remote installation assistance via TeamViewer is also available for seamless setup and operation.

Understanding DOOSAN Diagnostic Tool G2 Stage V

The DOOSAN Diagnostic Tool G2 Stage V is an essential software solution for maintaining and optimizing heavy machinery. It brings advanced diagnostic capabilities to ensure operational efficiency and regulatory compliance.

What is the DOOSAN Diagnostic Tool G2 Stage V?

The DOOSAN Diagnostic Tool G2 Stage V is a sophisticated software designed specifically for DOOSAN machinery. It enables technicians and operators to perform comprehensive diagnostics on various components of heavy equipment. This tool acts as a bridge between the machinery and the technician by providing crucial data relevant to performance issues.

Key Features of the G2 Stage V Tool

-

User-Friendly Interface

The software features a well-organized interface that simplifies navigation, making it accessible even for users with minimal technical skills.

-

Real-Time Monitoring

The tool allows for real-time monitoring of various systems within the machinery, providing updates on the engine’s health and performance.

-

Error Code Reading

Users can quickly scan for error codes, helping to identify issues promptly and minimize machine downtime.

-

Compatibility

The G2 Stage V Tool is compatible with a wide range of DOOSAN equipment, ensuring versatility across different applications.

-

Software Updates

Regular software updates keep the tool aligned with the latest technology trends and diagnostic practices, ensuring optimal performance.

Benefits of Using DOOSAN Diagnostic Software

Utilizing the DOOSAN Diagnostic Tool G2 Stage V offers numerous advantages to operators and companies in the machinery sector.

-

Enhanced Efficiency

Data-driven maintenance enhances operational efficiency, allowing for more productive use of equipment.

-

Cost-Effective Maintenance

By accurately diagnosing issues before they escalate, businesses can avoid costly repairs and reduce unnecessary downtime.

-

Regulatory Compliance

The software helps ensure that all operations adhere to environmental regulations, particularly those related to emissions and safety standards.

-

Informed Decision Making

The availability of detailed diagnostic information allows businesses to make informed decisions regarding maintenance and equipment usage.

DOOSAN Brand and Innovation

The DOOSAN brand is synonymous with excellence and innovation in the machinery industry. Over the years, it has consistently demonstrated a commitment to technological advancement and environmental responsibility.

History of the DOOSAN Brand

Founded in 1896, DOOSAN has evolved from its humble beginnings as a small retail company into a global leader in construction and industrial machinery. Initially focused on trade, it quickly expanded into various sectors, including construction, manufacturing, and engineering. The brand’s legacy has been built on the principles of quality, reliability, and customer satisfaction.

As the company grew, it dedicated significant resources to research and development, enabling it to remain competitive in an ever-evolving market. DOOSAN’s acquisition of several companies throughout the years has broadened its product offerings and technological capabilities. Today, it stands as a trusted name, known for innovative solutions that cater to the needs of the construction and manufacturing industries.

Innovations in Diagnostic Tools

DOOSAN’s relentless pursuit of innovation has led to the development of advanced diagnostic tools that enhance operational efficiency and reduce downtime. The company invests heavily in technology to ensure its products meet the highest standards of performance and reliability.

These diagnostic tools are designed with the user in mind, providing intuitive interfaces and real-time data analysis to facilitate maintenance and troubleshooting. Key innovations include:

- Advanced error detection capabilities, reducing the time spent on diagnostics.

- Enhanced interoperability with a wide range of DOOSAN equipment, improving overall usability.

- Continuous software updates that align with industry advancements and customer feedback.

DOOSAN’s commitment to innovation is evident in its proactive approach to addressing the challenges faced by machine operators and technicians. This focus on evolving technology ensures that the diagnostic tools remain efficient and effective in today’s demanding environments.

Environmental Commitment with Stage V Engines

As global environmental standards become more stringent, DOOSAN has placed a strong emphasis on sustainability and eco-friendly practices. The introduction of Stage V engines reflects this commitment, as they are designed to comply with the latest emissions regulations while maintaining the performance that DOOSAN is known for.

These engines not only reduce harmful emissions but are also engineered to optimize fuel efficiency, making them economically viable in the long term. DOOSAN’s environmental strategy encompasses:

- Investment in cleaner technologies and renewable energy sources.

- Development of machinery that minimizes the environmental impact during operation.

- Active participation in initiatives promoting sustainability across the industry.

This dedication to environmental responsibility positions DOOSAN as a forward-thinking leader in the machinery sector, aligning its operations with the global commitment to a greener future.

Detailed Overview of the G2 Stage V Tool

The G2 Stage V Tool is designed to deliver a comprehensive user experience for maintenance professionals. Its features, compatibility, and ongoing updates ensure that users can effectively manage and diagnose their machinery.

Software Interface and Usability

The software interface of the G2 Stage V Tool is intuitively designed for easy navigation and operational effectiveness. Users can quickly access various diagnostic features without encountering a steep learning curve. The layout is strategically organized, allowing users to view critical information at a glance.

Key characteristics of the interface include:

- User-Friendly Navigation: An organized menu structure promotes seamless access to different features such as diagnostics, updates, and maintenance logs.

- Visual Data Representation: Charts and graphs visually represent engine performance, making data interpretation straightforward.

- Multilingual Support: The interface supports multiple languages, including English and Korean, catering to an international user base.

Compatibility with DOOSAN Machines

This software has been engineered to work seamlessly with a broad spectrum of DOOSAN machinery. Its versatility ensures that operators can efficiently handle various models with a single tool. Compatibility checks are built into the system to verify the availability of diagnostic functions specific to the equipment in use.

Compatible equipment includes but is not limited to:

- Excavators

- Loaders

- Forklifts

- Dozers

This wide-ranging compatibility enhances the value of the G2 Stage V Tool, allowing companies to standardize their diagnostic processes across different machines, thus streamlining operations and improving efficiency.

Latest Updates and Improvements

The G2 Stage V Tool is equipped with a system for real-time updates, ensuring that users benefit from the latest enhancements and features. Regular updates bolster the tool’s functionality, address any bugs, and add new capabilities based on user feedback and technological advancements.

Recent improvements include:

- Enhanced Diagnostic Algorithms: Improved algorithms provide more accurate diagnostics and predictions regarding equipment performance.

- Faster Data Processing: Reductions in loading times lead to quicker access to diagnostic results, enhancing overall workflow efficiency.

- Improved User Support: New help features within the software offer guidance on troubleshooting and frequently asked questions directly in the interface.

These updates not only optimize the user experience but also contribute to the long-term sustainability of operations by ensuring machinery remains efficient and compliant with the latest industry standards.

Installation Guide for the G2 Stage V Tool

This guide provides detailed instructions for installing the G2 Stage V Tool, ensuring that users can set up the software efficiently and effectively.

System Requirements

Before proceeding with the installation, it is essential to check the system requirements to guarantee compatibility and optimal performance.

Operating System Compatibility

The G2 Stage V Tool requires the following operating system:

- Windows 11 (64-bit)

Hardware Specifications

Ensure that the computer meets the following hardware specifications:

- Processor: Dual-core 2.0 GHz or higher

- RAM: Minimum of 4 GB

- Available Disk Space: At least 2 GB of free space

- USB Port: Required for connection to diagnostic interfaces

Step-by-Step Installation Process

The installation process is straightforward and can be completed by following these steps:

Downloading the Software

The first step is to access the official Doosan platform to download the installation file. This file will be in a compressed format, which will be extracted during installation.

Running the Installer

After downloading, locate the installer file in the designated download folder. Right-click on the file and select “Run as Administrator” to begin the installation process. This ensures that the installer has the necessary permissions to complete its tasks efficiently.

Activating the Software

Once the installation is complete, the user will be prompted to activate the software. This typically involves entering a provided activation code, which should be done carefully to avoid errors. Upon successful activation, the G2 Stage V Tool will be ready for use.

Remote Installation Support via TeamViewer

For users who require additional assistance during the installation process, remote support is available through TeamViewer. This service allows a trained technician to access the user’s computer remotely, guiding them through the installation and troubleshooting any potential issues that may arise. This can greatly enhance the installation experience for those unfamiliar with the process.

Diagnostic Capabilities

The DOOSAN Diagnostic Tool G2 Stage V offers a range of advanced diagnostic capabilities essential for maintaining optimal performance in heavy machinery. The tool equips users with the necessary tools to read error codes, monitor systems in real-time, and conduct various functional tests. Each feature works in tandem to enhance the efficiency and reliability of DOOSAN equipment.

Reading and Interpreting Error Codes

This feature allows technicians to scan the machinery’s control systems for error codes. Understanding these codes is crucial for effective troubleshooting. The process typically involves:

- Connecting the diagnostic tool to the machinery.

- Initiating a scan to retrieve error codes stored in the system.

- Analyzing the codes to identify potential issues.

- Referencing the manufacturer’s code database for detailed definitions.

Efficiently reading and interpreting these codes minimizes downtime by targeting specific malfunction areas, ensuring prompt repairs and reducing operational costs.

Real-Time System Monitoring

Real-time system monitoring empowers technicians to observe the performance of various engine components and electronic systems as they operate. This feature allows for:

- Continuous tracking of engine parameters such as temperature, RPM, and fuel consumption.

- Immediate detection of irregularities or deviations from standard operating parameters.

- Forecasting potential failures before they lead to significant issues.

Real-time data acquisition helps in making informed decisions regarding maintenance and operational adjustments, ultimately enhancing the reliability of the machine.

Functional Component Tests

The tool’s capability to conduct functional component tests is an invaluable asset. This feature enables thorough evaluation of critical systems, ensuring everything runs as intended. This encompasses two key categories:

Engine Systems

Functional testing of engine systems involves assessing various parameters and components, which includes:

- Testing injector functionality to ensure optimal fuel delivery.

- Checking the integrity of ignition systems.

- Evaluating the performance of cooling systems.

These tests help in verifying operational efficiency, preventing unplanned breakdowns, and extending the lifespan of engine components.

Electronic Systems

Electronic systems are integral to modern machinery functionality. Testing these systems encompasses:

- Verifying sensor performance and accuracy.

- Assessing the functionality of the control unit.

- Monitoring communication between different electronic components.

By ensuring that electronic systems are functioning correctly, operators can maintain control and improve overall machinery performance, which is essential in high-demand environments.

Using the Diagnostic Tool for Maintenance

The DOOSAN Diagnostic Tool serves as an essential resource for conducting maintenance on heavy machinery. It streamlines routine checks and troubleshooting tasks, ensuring that equipment operates at peak performance.

Routine Maintenance Checks

Implementing routine maintenance checks is vital for preventing equipment failures and extending the lifespan of machinery. The diagnostic tool simplifies this process by providing a systematic approach to inspections. Key tasks include:

- Monitoring fluid levels and conditions.

- Inspecting belts and hoses for wear and tear.

- Verifying the functionality of safety systems.

- Assessing tire pressure and condition.

- Reviewing the battery’s health and connections.

These checks help identify potential issues before they escalate, minimizing downtime and repair expenses. Regular use of the diagnostic tool ensures that all components are operating within their specified parameters.

Troubleshooting Common Issues

Utilizing the diagnostic tool enables technicians to quickly diagnose issues that may arise during operation. The tool’s error code reading functionality plays a vital role in this process.

Engine Performance Issues

Engine performance issues can manifest in various ways, from reduced power output to erratic behavior during operation. By using the DOOSAN Diagnostic Tool, technicians can:

- Read and interpret engine fault codes.

- Analyze real-time data from engine sensors.

- Conduct performance tests to evaluate engine health.

These processes aid in pinpointing the root cause of issues, allowing for targeted repairs and adjustments.

Electronic Component Malfunctions

Modern machinery relies heavily on electronic components. Malfunctions in these systems can lead to significant challenges. The diagnostic tool assists in addressing electronic issues by:

- Providing diagnostic codes related to electronic failures.

- Facilitating communication between the diagnostic tool and the machine’s electronic control units (ECUs).

- Running specific tests to verify the functionality of electronic systems.

This capability helps ensure that electronic components function correctly, preventing operational disruptions.

Keeping Systems Updated

Maintaining up-to-date software is crucial for optimal performance of the diagnostic tool. Regular updates ensure that the tool remains compatible with the latest machinery advancements and incorporates new features. Key aspects of keeping systems updated include:

- Regularly checking for software updates.

- Following installation guidelines provided by DOOSAN.

- Utilizing automatic update features when available.

An updated diagnostic tool enhances its capabilities, ensuring that machinery benefits from the most efficient repair and maintenance processes.

Enhancing Efficiency with DOOSAN Diagnostic Tool

The DOOSAN Diagnostic Tool plays a vital role in optimizing the efficiency of machinery operations. It empowers technicians to monitor performance, troubleshoot issues, and implement enhancements that lead to better productivity and cost management.

Improving Operational Efficiency

Operational efficiency is critical in the field of heavy machinery. The DOOSAN Diagnostic Tool provides comprehensive insights into machine performance, helping users identify areas for improvement. It streamlines diagnostic processes, allowing for quicker resolution of issues. Key aspects include:

- Data-Driven Decisions: The tool offers real-time data analysis, enabling teams to make informed choices that enhance functionality.

- Optimized Machine Settings: Tailoring machine configurations through diagnostics can lead to significant performance improvements.

- Enhanced Communication: Sharing diagnostic data among team members minimizes miscommunication and ensures everyone is aligned with operational goals.

Reducing Downtime

Downtime can be a costly affair for businesses that depend on heavy machinery. This diagnostic tool is designed to mitigate unused time and boost productivity. Strategies to reduce downtime include:

- Proactive Maintenance: Regular diagnostic checks help anticipate failures before they occur, allowing for maintenance to be scheduled during non-operational hours.

- Swift Problem Identification: The ability to quickly read error codes enables technicians to address issues without unnecessary delays.

- Efficient Resource Allocation: Knowing the exact needs of machinery allows for better planning and allocation of maintenance resources, which further reduces machine idle time.

Cost Savings in Repairs and Maintenance

Investing in the DOOSAN Diagnostic Tool further translates into significant cost savings over time. By preventing major failures and minimizing repair costs, users can enjoy better financial management. Key points of cost efficiency include:

- Early Detection: By identifying issues early through diagnostics, businesses can avoid expensive repairs and extensive downtime.

- Reduce Labor Costs: Streamlined diagnostics and faster resolutions decrease the amount of labor required for maintenance tasks.

- Long-Term Equipment Longevity: Regular application of diagnostic tools leads to better maintenance practices, prolonging the lifespan of machinery.

Compliance and Environmental Benefits

Ensuring compliance with regulations and enhancing environmental benefits are crucial in today’s heavy machinery landscape. The integration of advanced diagnostic tools not only helps meet demanding industry standards but also supports sustainability goals.

Meeting Regulatory Requirements

Adhering to regulatory requirements is vital for any machinery operation. The DOOSAN diagnostic tools are designed to facilitate this compliance effectively. They enable users to:

- Monitor emissions closely to ensure they remain within legal limits.

- Identify and rectify issues that could lead to non-compliance.

- Generate reports for regulatory audits easily, offering clear documentation of adherence to standards.

Regular use of diagnostic tools assists businesses in avoiding penalties and complying with both local and international regulations. This proactive approach can prevent costly disruptions and enhance operational credibility.

Reducing Emissions with Stage V Engines

The introduction of Stage V engines marks a significant advancement in reducing emissions in heavy machinery. The integration of the G2 Stage V diagnostic tool supports these engines by:

- Providing insights into engine performance, which helps in optimizing fuel efficiency.

- Facilitating real-time monitoring of emission levels to ensure they stay within acceptable ranges.

- Identifying malfunctions that can lead to excessive emissions, allowing for timely repairs.

This commitment to minimizing emissions aligns with growing environmental standards and improves the sustainability of operations. Using these tools not only enhances machine performance but also contributes to a cleaner environment.

Long-Term Sustainability of DOOSAN Equipment

The sustainability of DOOSAN equipment is integral to its brand identity and operational strategies. The marriage of advanced diagnostics with innovative engineering ensures that these machines not only perform well but also contribute positively to environmental goals. This is achieved through:

- Enhanced longevity of machinery through regular maintenance and timely repairs.

- Adoption of eco-friendly technologies that significantly lower environmental footprints.

- Continuous updates and innovations that address emerging environmental challenges.

The ongoing commitment to sustainable practices ensures that DOOSAN equipment remains at the forefront of industry standards while helping operators achieve their operational and environmental goals.

Real-Time Updates and Software Support

The effectiveness of the DOOSAN Diagnostic Tool G2 Stage V is significantly enhanced by its robust real-time updates and comprehensive software support. These features are critical for maintaining optimal performance and ensuring compliance with the latest industry standards.

Accessing Software Updates

Software updates for the DOOSAN Diagnostic Tool G2 Stage V can be easily accessed through the program’s built-in update feature. This allows users to download the latest enhancements and bug fixes directly, ensuring that they always work with the most current version. Regular updates help in addressing any known issues while introducing new functionalities that improve usability and performance.

Benefits of Automatic Updates

Automatic updates streamline the user experience by reducing the need for manual intervention. Key benefits include:

- Continuous Access to New Features: Users are always equipped with the latest tools and diagnostic capabilities.

- Time Efficiency: Automatic updates save valuable time, allowing users to focus on maintenance tasks rather than software management.

- Enhanced Security: Regular updates help protect against potential security vulnerabilities that could compromise system integrity.

- Improved Compatibility: Ensures seamless integration with new machinery models and evolving industry standards.

Technical Support Channels

Robust technical support is available to assist users with any challenges they may encounter while using the diagnostic software. This support is provided through various channels, ensuring that help is readily accessible.

Email Support

For detailed inquiries or specific technical issues, users can reach out via email. This method is ideal for sending attachments, such as screenshots or error logs, to better illustrate the problem. Responses are typically prompt, allowing users to resolve their issues quickly.

WhatsApp Support

WhatsApp offers a more immediate means of communication, allowing users to receive real-time responses to their questions. This channel is particularly useful for troubleshooting simple issues or seeking quick clarifications on software functionalities.

Telegram Support

For users who prefer a more community-oriented approach, Telegram serves as another effective support channel. It not only facilitates direct communication with support personnel but also enables users to connect with others in the DOOSAN community, sharing tips and experiences related to the software.

Frequently Asked Questions (FAQs)

This section addresses common inquiries regarding the DOOSAN Diagnostic Tool, aiming to clarify its functionalities, compliance with Stage V and T4F standards, as well as troubleshooting tips for users seeking support.

General Questions About DOOSAN Diagnostic Tool

Understanding the capabilities and features of the DOOSAN Diagnostic Tool is essential for maximizing its use in maintenance and diagnostics. Below are the answers to some frequently asked questions regarding its general specifications and functionalities.

- What types of machinery are compatible with the DOOSAN Diagnostic Tool?The tool is designed to work with a wide range of DOOSAN equipment, including excavators, wheel loaders, and other construction machinery. It is important to check compatibility with specific models to ensure optimal performance.

- Do I need special training to use the DOOSAN Diagnostic Tool?While prior experience with diagnostic tools can be beneficial, the software features an intuitive interface designed for ease of use. Users are encouraged to familiarize themselves with the user manual and tutorials available for a seamless experience.

- Is the software regularly updated?Yes, the DOOSAN Diagnostic Tool receives regular updates to enhance functionalities and comply with evolving industry standards. Users have access to these updates automatically or can opt to download them manually.

Specific Questions About Stage V and T4F Compliance

Ensuring compliance with Stage V and T4F regulations is crucial for users aiming to operate machinery within legal environmental standards. Here are some specific questions related to compliance:

- What is Stage V compliance, and why is it important?Stage V compliance refers to the European Union’s emissions legislation aimed at reducing harmful pollutants from machinery. It is important because it helps in minimizing environmental impact and in meeting government regulations.

- Does the DOOSAN Diagnostic Tool support T4F engines?Yes, the DOOSAN Diagnostic Tool includes features specifically designed for T4F engines, ensuring that users can monitor and diagnose these systems effectively to meet compliance standards.

- How can I verify my machinery’s compliance status?The diagnostic software allows users to monitor emission levels and ensure that all systems are functioning within the required parameters. Error codes related to emissions will be clearly displayed for troubleshooting.

Troubleshooting FAQs

Common issues can arise during the use of the DOOSAN Diagnostic Tool. This section provides guidance on troubleshooting common problems encountered by users.

- What should I do if I encounter error codes?Error codes are generated to indicate specific problems within the machinery. Users should consult the error code list in the tool’s manual, which provides detailed explanations and recommended actions for each code.

- How do I perform a system reset?To perform a system reset, navigate to the settings menu within the software and select the reset option. This action will usually resolve minor issues related to software performance.

- I am having trouble connecting the diagnostic tool to my machinery.Ensure that all connections are secure and that the correct settings are selected for the specific equipment model. Checking the USB connection and verifying that the software is up to date can also resolve connection issues.

Optimizing Your Setup for Maximum Efficiency

To achieve the best results when using the diagnostic tool, proper setup and positioning are crucial. Effective use of real-time data can significantly enhance operational capabilities and forecast potential issues.

Best Practices for Setup

Positioning Your Diagnostic Kit

The physical arrangement of your diagnostic kit can impact its performance and efficiency. Ensure the following:

- Place the diagnostic tool in a well-ventilated area to prevent overheating.

- Avoid direct sunlight exposure, which may cause screen glare and affect visibility.

- Organize necessary cables and connectors to eliminate clutter and facilitate easy access during diagnostics.

- Position the kit close to the machinery being monitored to reduce the length of cables needed, minimizing potential interference.

Calibration Tips

Calibration is essential for accurate readings and troubleshooting. The following steps are recommended:

- Perform calibration regularly to maintain accuracy, following the manufacturer’s instructions.

- Ensure that the machinery is at operating temperature before calibrating to obtain optimal results.

- Record baseline measurements to understand normal operating parameters and identify deviations effectively.

Leveraging Real-Time Data for Forecasting

Utilizing real-time data can enhance decision-making and preventive maintenance strategies.

- Monitor engine performance continuously to detect anomalies early, allowing for immediate corrective actions.

- Analyze historical data trends alongside real-time updates to better understand performance patterns.

- Utilize data analytics tools to predict potential issues before they escalate into costly repairs or extended downtime.

- Regularly review system alerts and notifications for timely responses to emerging problems.

Case Studies and Testimonials

This section presents real-world applications and feedback from users who have integrated the DOOSAN Diagnostic Tool G2 Stage V into their operations. The experiences shared highlight the software’s impact on efficiency, cost savings, and overall maintenance strategy.

Success Stories from DOOSAN Users

Numerous users have reported significant improvements in their operational workflows after adopting the G2 Stage V diagnostic tool. These success stories indicate a trend where companies have achieved enhanced performance and reduced downtime:

-

Case Study: Heavy Equipment Rental Company

A heavy equipment rental company experienced frequent machinery malfunctions. After implementing the G2 Stage V tool, technicians could diagnose issues faster, resulting in a 30% reduction in repair time.

-

Case Study: Construction Firm

A construction firm integrated the diagnostic tool in its fleet management system. By leveraging the real-time monitoring feature, they minimized unforeseen equipment failures, increasing project completion rates by 25%.

Testimonials on Efficiency Improvements

User testimonials reflect the widespread appreciation for the efficiency gains provided by the diagnostic tool. Below are some highlights from actual users regarding their experiences:

-

Testimonial from a Fleet Manager

“Since we started using the DOOSAN Diagnostic Tool G2 Stage V, we’ve seen a remarkable improvement in our machinery’s performance. The ability to read error codes and monitor systems in real time has transformed our maintenance approach.”

-

Testimonial from a Service Technician

“The user-friendly interface makes it easy to diagnose issues. It has significantly reduced the time we spend on repairs and increased our team’s productivity. We now handle maintenance more effectively than ever.”

Case Studies on Cost Savings

Cost management is a critical component of any operation involving heavy machinery. The following case studies illustrate how using the G2 Stage V tool has led to substantial cost reductions:

-

Case Study: Agricultural Equipment Provider

Upon adopting the diagnostic software, the agricultural equipment provider reported a decrease in maintenance costs by 40%. Early detection of mechanical issues reduced extensive repair bills.

-

Case Study: Infrastructure Development Corporation

By optimizing their maintenance schedules with the G2 Stage V tool, the corporation minimized downtime and saved thousands annually, proving the value of proactive diagnostics in capital-intensive projects.

Future of DOOSAN Diagnostic Tools

The future of DOOSAN Diagnostic Tools is shaped by ongoing advancements in technology, industry demands, and user expectations. Continuous innovation will enhance the utility and effectiveness of these tools, ensuring optimal performance for heavy machinery.

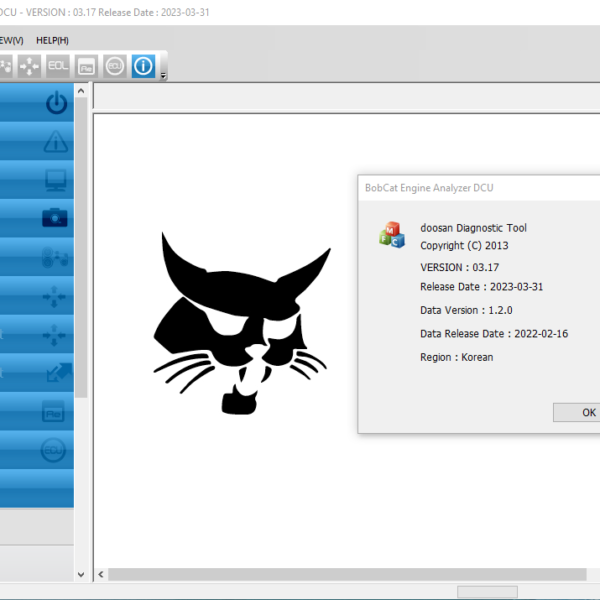

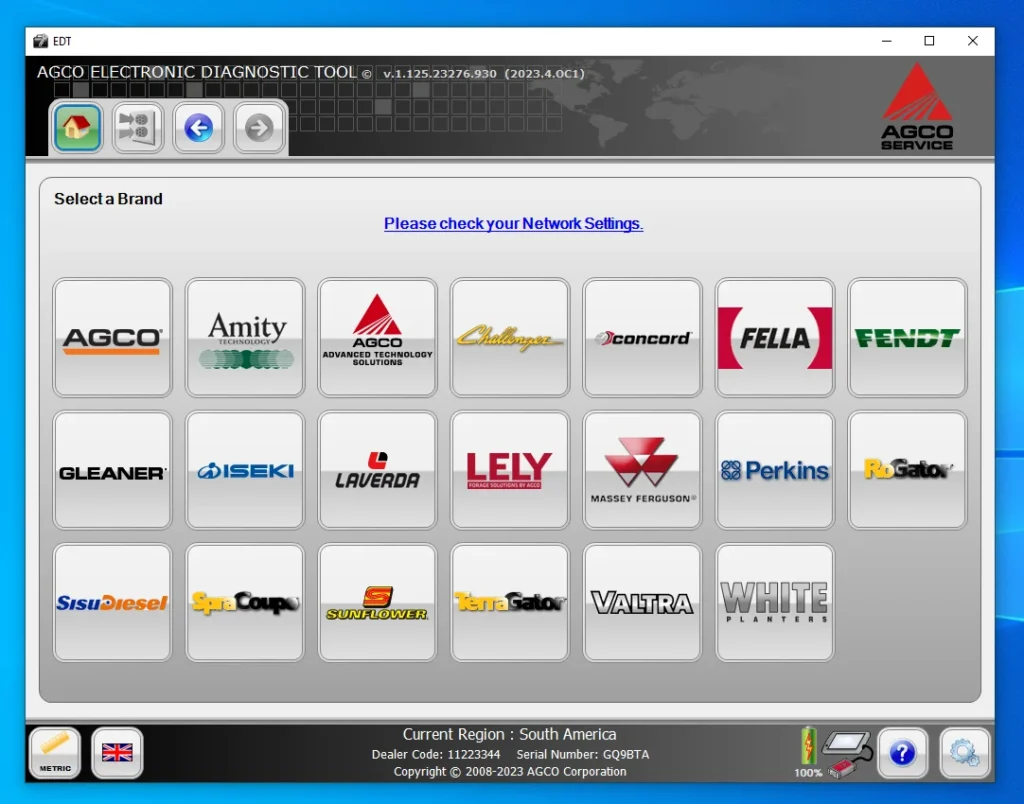

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

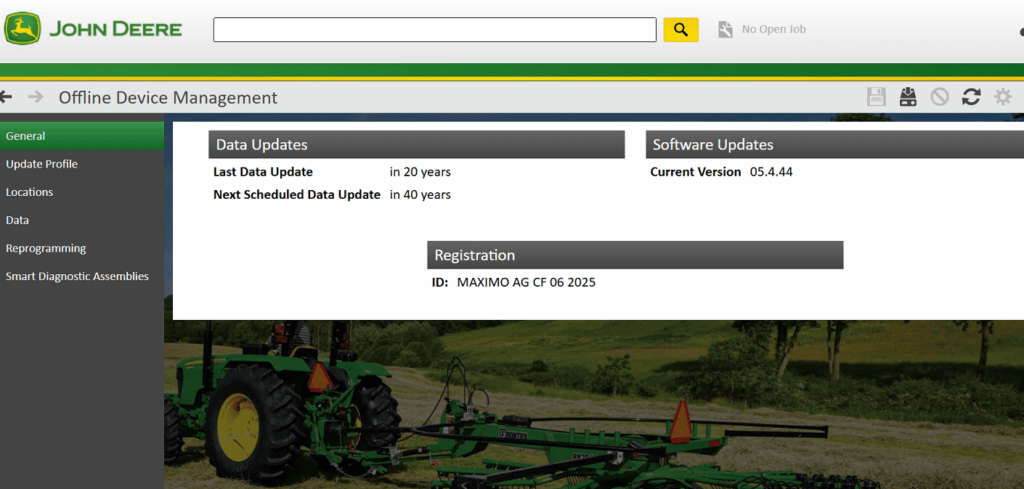

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

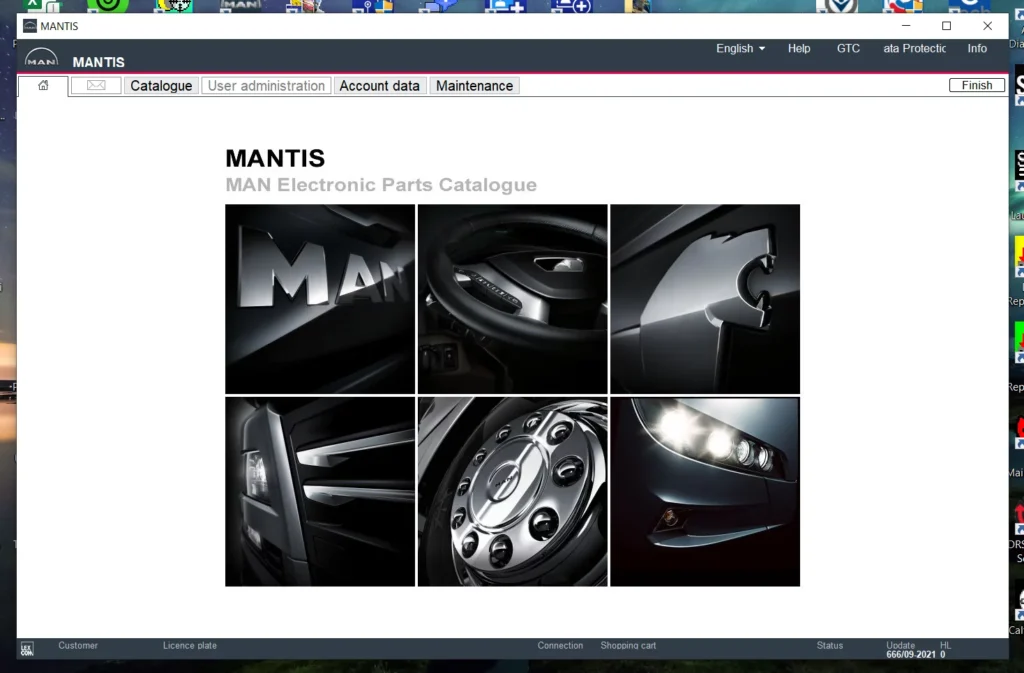

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer 01.00R5 [2024.03] is designed for optimal engine performance in marine applications. This tool offers advanced diagnostic capabilities and is compatible with a variety of marine engines. It plays a crucial role in maintaining and managing engine health. The latest version includes features that enhance connectivity and user experience, making it a valuable asset for marine operators and technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-ECU-ANALYZER-01.00R5-2024.03.png)

Reviews

Clear filtersThere are no reviews yet.