DOOSAN DIAGNOSTIC TOOL EURO6 DIESEL SCAN ECU 00 24 2023: Upgrade Your Truck Diagnostics Today!

The DOOSAN DIAGNOSTIC TOOL EURO6 DIESEL SCAN ECU 00.24 (2023) is an essential software solution for diagnosing diesel engines. It offers advanced features to enhance engine performance and ensure compliance with emission standards. This tool is designed for various Doosan engine models, providing real-time data monitoring and fault code management. With easy installation and remote support via TeamViewer, it is an invaluable resource for technicians and workshops looking to optimize their maintenance processes.

Importance of Diagnostic Tools for Diesel Engines

The significance of diagnostic tools in the realm of diesel engines cannot be overlooked. These advanced technologies play a crucial role in ensuring optimal performance, compliance with regulatory standards, and minimizing operational costs.

Role in Emission Control

In recent years, the focus on reducing emissions from diesel engines has intensified, primarily due to stricter environmental regulations. Diagnostic tools are essential for maintaining compliance with these regulations by facilitating efficient monitoring and management of emissions.

These tools help in identifying potential issues that may lead to increased emissions, allowing for timely interventions. By providing insights into the operation of various components, they ensure that the engine operates within the required parameters. This proactive approach not only aids in meeting legal requirements but also contributes to a cleaner environment.

Preventive Maintenance Benefits

Preventive maintenance is critical in extending the lifespan of diesel engines and ensuring their reliability. Diagnostic tools enable in-depth assessments of engine health and performance, helping technicians detect issues before they escalate into major failures.

- Regular performance checks can identify wear and tear on crucial components.

- Early detection of potential malfunctions reduces the risk of unexpected breakdowns.

- Implementing a proactive maintenance schedule based on diagnostic insights minimizes emergency repairs and associated costs.

These benefits translate to improvements in operational efficiency as engines remain functional and effective throughout their intended lifespan. Furthermore, systematic maintenance practices foster trust and satisfaction among customers relying on diesel-powered equipment.

Cost Efficiency and Downtime Reduction

Cost management is a pivotal aspect of running any machinery-intensive operation. Diagnostic tools significantly enhance cost efficiency by reducing downtime and maintenance expenses.

Here are a few key points regarding their impact on costs:

- By diagnosing problems early, repairs can be scheduled during regular maintenance periods, minimizing disruption in operations.

- Identifying inefficiencies, such as fuel consumption issues, can lead to optimized performance and reduced operational costs.

- Long-term use of diagnostic tools often results in noticeable savings as they allow for better allocation of resources and informed decision-making.

Overall, utilizing diagnostic tools fosters a culture of continuous improvement in diesel engine management. This approach translates to tangible benefits in both financial and operational aspects, reinforcing the indispensable role that technology plays in modern diesel engine maintenance.

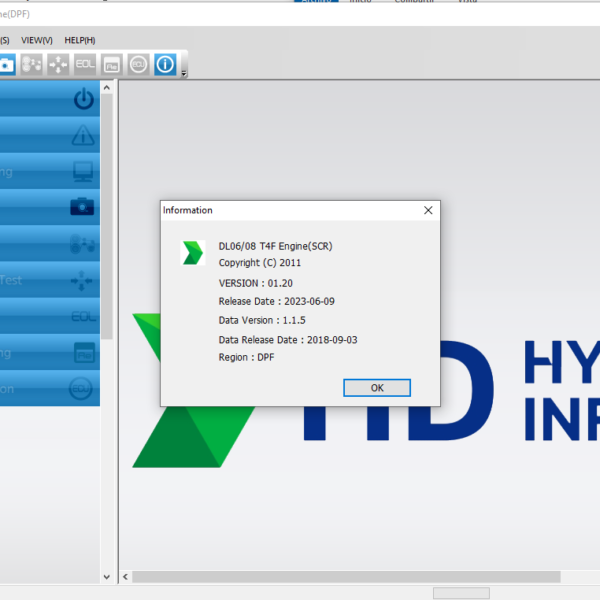

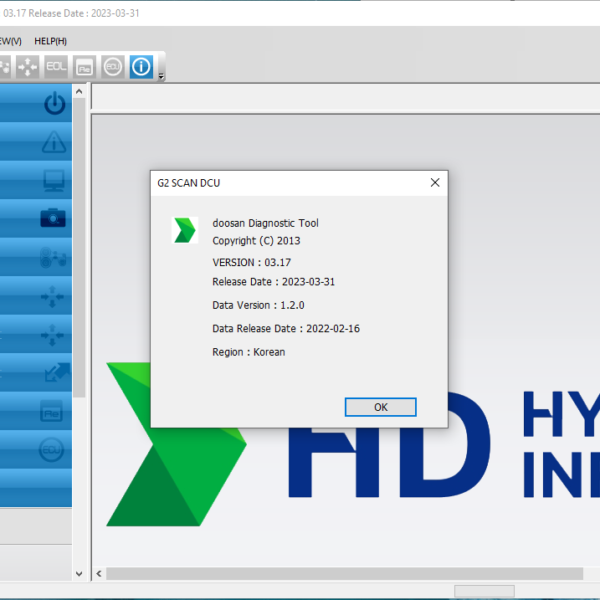

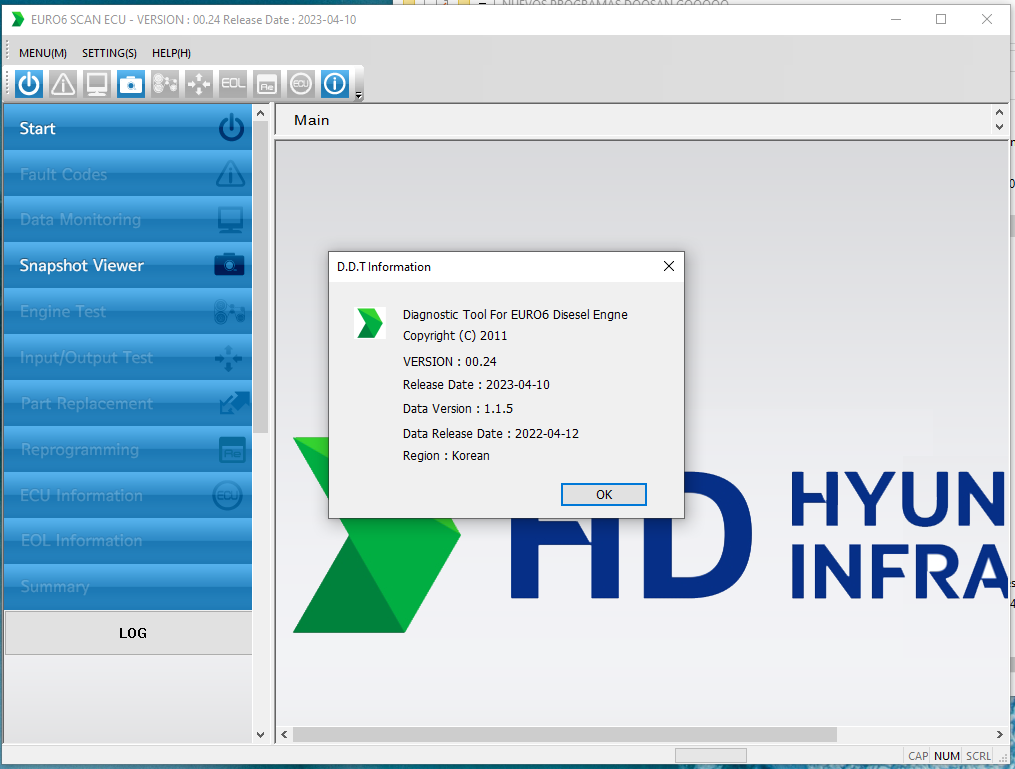

Overview of DOOSAN DIAGNOSTIC TOOL EURO6 DIESEL SCAN ECU 00 24 2023

The DOOSAN DIAGNOSTIC TOOL EURO6 DIESEL SCAN ECU 00.24 (2023) represents a significant advancement in diesel engine diagnostics. With its cutting-edge features and enhancements, it is tailored to meet the needs of modern technicians and service providers in the transportation and heavy machinery sectors.

Key Features

This diagnostic tool integrates various functionalities designed for optimal performance in diesel engine monitoring and maintenance.

Compatibility with Various Doosan Engines

The DOOSAN DIAGNOSTIC TOOL is engineered to work seamlessly with a wide range of Doosan engines, including models such as DL06, DL08, DV11, and DV11S. This broad compatibility ensures that users can effectively diagnose and manage multiple engines in their fleet, streamlining their repair processes and improving overall efficiency.

Software and Hardware Requirements

To run the DOOSAN DIAGNOSTIC TOOL, users must ensure their systems meet specific criteria. The software requires a minimum operating system of Windows 11 x64 for optimal functionality. The installation process involves managing a 328 MB download, which expands to 918 MB once installed. Proper hardware specifications are crucial for maintaining performance during diagnosis sessions.

Multi-language Support

Recognizing the global demand for its products, Doosan has incorporated multi-language support into this diagnostic tool. Available languages include English and Korean, making it accessible for a diverse array of users in different regions. This feature enhances usability, allowing technicians from various backgrounds to navigate the tool with ease.

Why Choose DOOSAN for Diesel Engine Diagnostics?

Choosing Doosan for diesel engine diagnostics comes with distinct advantages that cater to both professionals and organizations focused on efficiency and effectiveness in maintenance routines.

- Advanced Diagnostic Capabilities: The DOOSAN DIAGNOSTIC TOOL is equipped with state-of-the-art technology that facilitates thorough engine analysis, identifying problems quickly and accurately.

- Reliable and Efficient: Users can depend on this tool to deliver consistent performance, ensuring minimal downtime for their equipment.

- Continuous Updates: The software receives regular updates, which means users have access to the latest diagnostic enhancements and features, keeping them ahead in the industry.

- User-friendly Interface: A graphical and intuitive user interface streamlines navigation and operation, making it easier for technicians to focus on diagnostics rather than grappling with complicated software.

The combination of these features establishes the DOOSAN DIAGNOSTIC TOOL as a leading choice among technicians and workshops that prioritize accurate diagnostics and effective maintenance strategies.

Detailed Features and Specifications

This section delves into the specific features and capabilities of the diagnostic tool, showcasing its strengths and tailored functionalities for diesel engines.

Real-time Data Monitoring

The ability to monitor engine parameters in real-time is crucial for effective diagnosis and maintenance. This feature enables technicians to track various indicators that contribute to optimal engine performance.

Engine Parameters Observed

- Oil Pressure: Monitoring oil pressure helps identify potential lubrication issues that could lead to engine wear or failure.

- Engine Temperature: Keeping tabs on the temperature ensures the engine operates within safe limits and prevents overheating.

- Fuel Efficiency: Real-time fuel consumption data allows for an assessment of efficiency, helping to optimize operations.

- Exhaust Gas Temperature: This metric is vital for evaluating emissions and the effectiveness of the exhaust after-treatment systems.

- Boost Pressure: Monitoring boost pressure helps in assessing the turbocharger’s performance and overall engine power output.

Use Cases and Scenarios

Real-time data monitoring can be applied across various scenarios. For example, during routine maintenance, technicians can make informed decisions based on immediate data feedback. In case of an engine performance drop, real-time insights enable quick diagnoses, facilitating timely interventions. Additionally, field technicians benefit from real-time data as they can address issues immediately while on-site, reducing the need for extensive troubleshooting later.

Reading and Clearing Fault Codes

This tool enhances the efficiency of diagnosing engine problems by allowing users to read and clear fault codes with ease. Understanding and managing these codes are essential for maintaining engine health.

Common Error Codes Explained

- Diagnostic Trouble Codes (DTCs): These codes provide direct insights into specific malfunctions in the engine or connected systems.

- Environmental Codes: Fault codes linked to emission controls help ensure compliance with environmental regulations.

- Sensor Malfunction Codes: These codes indicate failures in various sensors, which are critical to the engine’s functioning.

Steps to Clear Faults

Clearing faults is a straightforward process. After diagnosing an issue and enacting repairs, technicians can follow specific steps to clear stored error codes from the ECU. This not only resets the system but also ensures that new diagnostics can be started fresh. Typically, the process involves accessing the fault code menu on the diagnostic tool, selecting the relevant codes, and executing the clear command. It is essential to confirm that all repairs are completed before clearing codes to prevent misdiagnosis.

Programming and Configuration Capabilities

The programming and configuration functionalities of the DOOSAN tool enhance its utility, offering advanced options for engine management and performance optimization.

Software Updates

Regular software updates are vital to ensure that users have access to the latest features and bug fixes. Keeping the software current allows technicians to address new engine models and address any performance issues reported by manufacturers. Regular checks for updates can lead to significantly improved diagnostic accuracy and operational efficiency.

Electrical Configuration Options

- Custom Parameter Adjustments: Technicians can customize certain engine settings to optimize performance based on operational requirements.

- Integration with Other Systems: The tool supports configurations that allow for seamless integration with accessories and additional diagnostic systems.

Graphical and Intuitive Interface

The user interface of the diagnostic tool is designed to be both visually appealing and highly functional, promoting ease of use for technicians at any skill level.

User Interface Design

The layout is streamlined, with essential functions readily accessible. Graphical representations of data provide quick visual insights into engine performance, making it easier for technicians to understand complex information at a glance. Clear labeling and intuitive navigation enable users to operate the system without extensive training, reducing the learning curve significantly.

Ease of Use for Technicians

Technicians appreciate a tool that minimizes complexity while maximizing functionality. The DOOSAN DIAGNOSTIC TOOL is crafted for accessibility, allowing even those with limited experience to perform effective diagnostics. Comprehensive tooltips and guidance during operation aid users in navigating through the various functions seamlessly. This practical approach ensures that the tool can be employed efficiently in both shop environments and fieldwork.

Installation and Usability

Understanding the installation process and usability features of the software is essential for ensuring optimal performance and ease of use. This section delves into the installation steps, remote support options, and the various versions of the software available for users.

Step-by-Step Installation Guide

Installing the DOOSAN DIAGNOSTIC TOOL requires careful attention to detail to ensure a successful setup. Below is a comprehensive guide to assist in the installation process.

Downloading and Setting Up the Software

The first step involves downloading the installation files from a trusted source. The software is provided in a compressed format which must be extracted before installation. Users must follow these steps:

- Visit the reliable website hosting the software.

- Locate the DOOSAN DIAGNOSTIC TOOL download link.

- Click to download the compressed file.

- Once downloaded, navigate to the file location and extract the contents.

- Open the extracted folder to run the setup file, following on-screen prompts to complete the installation.

After the initial setup, users are encouraged to check for any outstanding updates to ensure the software has the latest features and bug fixes.

Using the Keygen for Activation

Activation is a critical step that unlocks the full potential of the software. After installation, users will need to utilize a keygen to activate the product. This process includes:

- Running the keygen application supplied with the installation files.

- Following the prompts to generate a unique activation code.

- Inputting the generated code into the software to complete the activation process, ensuring that all functions are accessible.

It is crucial to adhere to legal guidelines when using software activation tools and to ensure that the keygen is used responsibly.

Remote Installation Support via TeamViewer

In instances where users encounter challenges during installation, remote support via TeamViewer provides an effective solution. This feature allows technicians to assist users directly from their own devices.

How to Access Remote Support

To benefit from remote support, users need to have TeamViewer installed. The process includes:

- Downloading and installing the TeamViewer application from its official website.

- Launching TeamViewer and noting the ID and password generated.

- Contacting support personnel and providing them with the ID and password for secure access.

Once connected, the technician can guide the user through the installation process or troubleshoot any existing issues seamlessly.

Ensuring Proper Setup and Functionality

After installation, it is important to verify that the software is functioning correctly. Users should check:

- All features are accessible and working as intended.

- The software interface loads without errors.

- Real-time data monitoring and diagnostic functions operate smoothly.

Regular checks and updates will help maintain system integrity and extend the software’s effective life span.

Choosing Between Locked and Unlocked Versions

Users have the option to select between locked and unlocked versions of the software, each catering to different needs and preferences.

Advantages of Each Option

The choice between locked and unlocked versions carries several implications:

- Unlocked Version: Offers complete access to all features without restrictions, ideal for users requiring extensive functionality.

- Locked Version: May limit certain features or access depending on specific configurations, suited for users with standard diagnostic needs.

Evaluating the intended use will assist in making the right choice based on operational demands.

What Users Need to Know

Understanding the differences between the versions is critical. Users should consider:

- Long-term goals for diagnostics and maintenance.

- The capability requirements based on the range of Doosan engines and machinery utilized.

- Cost implications associated with licensing and feature access.

By taking these factors into account, users can ensure that they select the software version that best aligns with their operational requirements.

Practical Applications and Benefits

In the realm of diesel engine diagnostics, practical applications and the resultant benefits play a pivotal role in ensuring optimal performance and longevity. The utilization of advanced diagnostic tools significantly enhances workflow efficiency and service delivery.

Use in Authorized Service Workshops

Authorized service workshops utilize diagnostic tools to provide thorough and accurate assessments of diesel engines. The integration of such technology allows technicians to quickly pinpoint issues, reducing the time spent on repairs. This technology streamlines service processes and ensures compliance with strict emission standards, especially under the EU regulations.

Implementing a sophisticated diagnostic tool empowers workshops to offer:

- Enhanced customer trust through reliable diagnostics.

- Efficient service turnaround times, leading to increased customer satisfaction.

- Access to comprehensive reporting features, allowing for informed decision-making on repairs.

Field Diagnostics for Technicians

Field diagnostics have revolutionized the way technicians approach engine maintenance and troubleshooting. Having the ability to perform diagnostics on-site reduces downtime significantly. Technicians can detect issues before they escalate, which ultimately saves time and cost for both service providers and customers.

Benefits On-Site

Performing diagnostics in the field presents several advantages:

- Immediate response to equipment failures, minimizing operational disruptions.

- Enhanced flexibility in service delivery, allowing technicians to adapt to various conditions.

- Reduced need to transport machinery to service centers, saving logistical costs.

Real-World Examples

There are numerous instances where field diagnostics have proven to be invaluable. For example, a technician dispatched to a construction site was able to identify a severe fault in an excavator’s engine without the need for its transport to the workshop. By utilizing diagnostic tools on-site, the issue was resolved within hours, allowing for minimal disruption to project timelines.

In another case, a fleet management company benefited from the capability to monitor multiple vehicles in real-time. This proactive approach resulted in a notable reduction in emergency repairs and improved overall fleet performance.

Such practical applications exemplify how these tools effectively enhance service outcomes, lead to significant cost savings, and foster stronger relationships between service providers and their clients.

Purchasing, Licensing, and Support

When considering the DOOSAN DIAGNOSTIC TOOL, understanding the purchasing process, licensing structure, and available support options is crucial for maximizing its utility.

How to Purchase from ecmtrucks.com

Purchasing the DOOSAN DIAGNOSTIC TOOL from ecmtrucks.com is a straightforward process designed for ease of use. The website offers a user-friendly interface that simplifies navigation and ensures that potential buyers can find exactly what they need.

Product Listings and Descriptions

ecmtrucks.com showcases comprehensive product listings that provide essential information about the DOOSAN DIAGNOSTIC TOOL. Each listing includes:

- Detailed descriptions of the software capabilities.

- Compatibility information with various Doosan engine models.

- System requirements for smooth installation and operation.

- User reviews that offer insights into the tool’s performance and reliability.

This thorough information empowers buyers to make informed decisions that suit their specific diagnostic needs.

Adding to Cart and Checkout Process

Once a buyer selects the desired product, adding it to the cart is a simple step. The checkout process is streamlined, ensuring that users can complete their purchases efficiently. Customers are guided through secure payment options, providing peace of mind with every transaction.

Licensing Details

The licensing structure for the DOOSAN DIAGNOSTIC TOOL is designed to provide flexibility and long-term access to the software. Understanding the licensing options helps users benefit from the tool fully.

Unlimited License Benefits

Purchasing the DOOSAN DIAGNOSTIC TOOL includes an unlimited license, which comes with several advantages:

- No expiration date, allowing for continuous use without the need for renewal.

- The freedom to utilize the software across multiple diagnostic tasks and projects.

- Access to all updates and enhancements as they are released, ensuring users benefit from the latest features and improvements.

Renewal and Update Processes

Although the unlimited license negates the need for regular renewals, it is important for users to stay informed about software updates. Regularly checking for updates can enhance the tool’s performance and maintain compatibility with new engine models or industry standards.

Contact and Support Information

Reliable support is vital for troubleshooting and maximizing the effectiveness of any diagnostic tool. ecmtrucks.com provides various support options to assist customers.

Customer Service Options

Customer service is available to address any inquiries regarding purchases, licensing, or general product questions. Dedicated representatives are knowledgeable and ready to provide assistance, ensuring a smooth user experience.

Technical Support and Troubleshooting

In addition to general customer support, ecmtrucks.com offers specialized technical support for the DOOSAN DIAGNOSTIC TOOL. This includes:

- Guidance on installation and setup.

- Assistance with activation via the provided keygen.

- Help with resolving technical issues encountered during use.

By providing comprehensive support, ecmtrucks.com ensures that users can effectively utilize the DOOSAN DIAGNOSTIC TOOL for their diagnostic and maintenance needs.

Maximizing the Value of DOOSAN DIAGNOSTIC TOOL

To fully leverage the capabilities of the DOOSAN DIAGNOSTIC TOOL, users should focus on comprehensive training and integration with complementary diagnostic systems. This approach enhances the diagnostic process and cultivates a deeper understanding of the tool’s functionalities.

Training and Certification for Users

Investing in training and certification ensures that users are well-equipped to utilize the software’s full potential. A properly trained technician can diagnose issues more effectively, leading to better maintenance outcomes.

Recommended Training Programs

- Online Courses: Many providers offer certification programs tailored to the DOOSAN DIAGNOSTIC TOOL. These courses cover essential features, best practices, and troubleshooting techniques.

- Hands-On Workshops: In-person workshops provide practical experience, allowing users to engage directly with the software and receive guidance from industry experts.

- Manufacturer Resources: DOOSAN may provide official training materials, webinars, and tutorials, which can be valuable for understanding updates and new features.

Understanding Diagnostic Reports

Grasping how to interpret diagnostic reports generated by the tool is fundamental for effective troubleshooting. These reports offer crucial insights into engine performance and potential issues.

- Key Metrics: Users should familiarize themselves with the critical metrics that the tool monitors, such as oil pressure, engine temperature, and fault codes.

- Error Code Interpretation: Learning to decode error codes can significantly expedite the troubleshooting process. Each code links to specific issues that require tailored solutions.

Integrating with Other Diagnostic Solutions

The ability to integrate the DOOSAN DIAGNOSTIC TOOL with other systems enhances its utility and effectiveness. Compatibility with additional diagnostic tools supports a more holistic approach to engine maintenance and monitoring.

Compatibility with WABCO and NEXIQ

Integration with systems like WABCO and NEXIQ allows for comprehensive diagnostics, ensuring that technicians can address a wider range of issues within the same interface.

- Unified Diagnostics: Utilizing multiple diagnostic solutions concurrently can streamline the troubleshooting process and provide a broader view of vehicle health.

- Enhanced Data Sharing: These integrations facilitate data sharing between systems, ensuring that technicians have all relevant information at their fingertips.

Comprehensive Diagnostic Strategies

Employing a multifaceted diagnostic strategy is essential for maximizing the value of the DOOSAN DIAGNOSTIC TOOL. This entails using a combination of tools and approaches to cover all bases in engine diagnostics.

- Preventative Maintenance: Regular diagnostics can prolong the lifespan of equipment by catching issues before they escalate into major problems.

- Data Analysis: Analyzing trends from diagnostic reports over time can help identify recurring issues, allowing for proactive solutions.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.