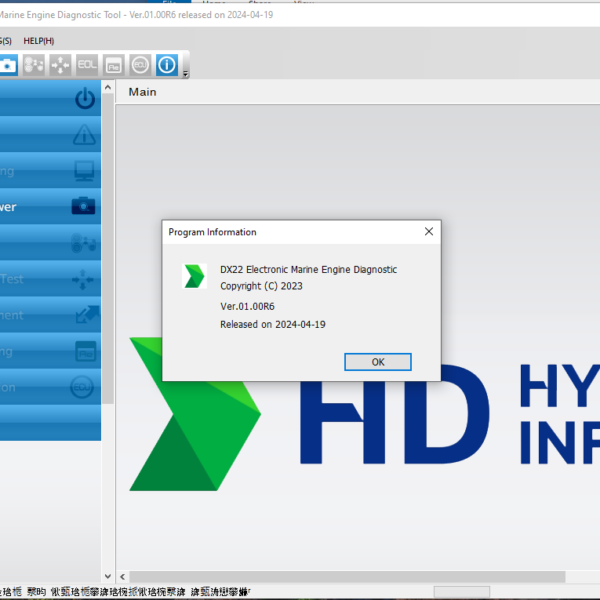

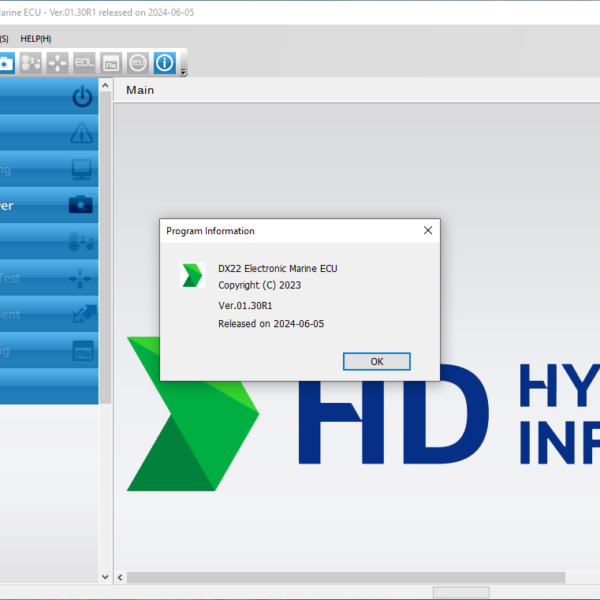

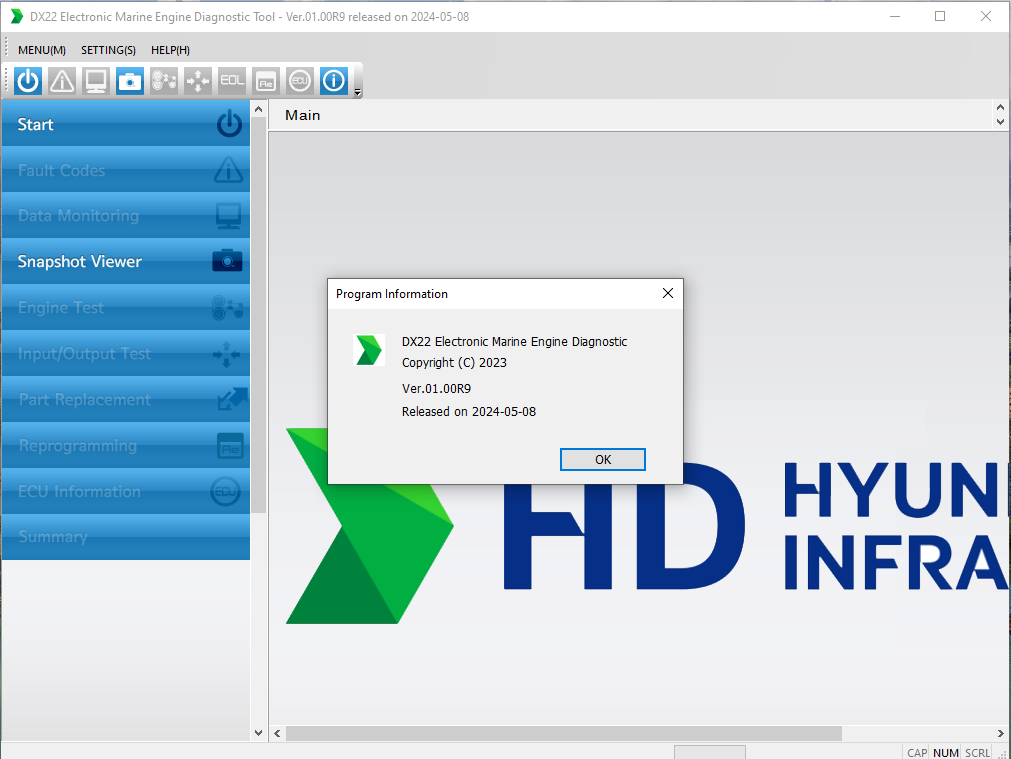

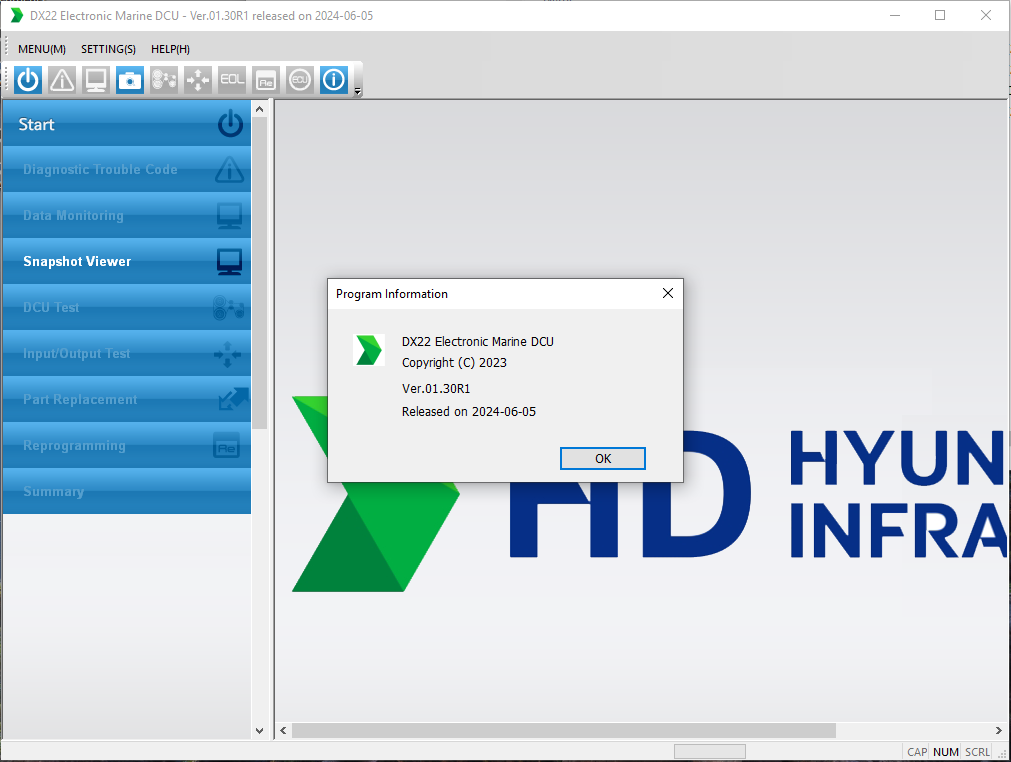

DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R9 [2024.05]: The Ultimate Solution for Marine Engine Diagnostics

The DOOSAN DIAGNOSTIC TOOL DX22 is a crucial electronic marine ECU analyzer designed for efficient diagnostics of marine engines. It offers a range of features tailored to meet the needs of technicians in the maritime industry. With advanced capabilities, the DX22 aids in error code reading and real-time monitoring. Its user-friendly interface and compatibility with various Doosan marine engines make it an essential tool for engine maintenance and performance optimization.

Doosan Infracore: A Legacy of Innovation

Doosan Infracore has established itself as a beacon of technological advancement in the machinery and engine industry. Its commitment to excellence and innovation continues to drive progress in various sectors, particularly in marine engineering.

History of Doosan Infracore

Founded in the early 20th century, Doosan Infracore began its journey as a small company with a focus on the manufacturing of machine tools. Over the decades, it evolved into a global powerhouse, expanding its portfolio to include a wide range of heavy machinery and industrial equipment. Key milestones in its history include:

- The introduction of innovative technologies in the 1960s that set new standards in machinery performance.

- Strategic acquisitions in the 2000s that enriched its research and development capabilities.

- Recognition as a leader in sustainable development, focusing on environmentally friendly operations and products.

Today, Doosan Infracore is recognized not only for its manufacturing prowess but also for its role in shaping the future of engine technology, especially in marine applications.

Evolution in Marine Engine Technology

The evolution of marine engine technology at Doosan Infracore has been marked by a relentless pursuit of efficiency, reliability, and environmental sustainability. Various advancements have included:

- Development of high-performance diesel engines specifically designed for marine environments.

- Integration of advanced control systems that enhance engine efficiency and reduce emissions.

- Introduction of diagnostic tools that streamline maintenance and improve operational safety.

As the marine industry faces increasing regulatory pressures and technological demands, Doosan Infracore continues to innovate, ensuring that its products not only meet but exceed industry standards.

Overview of the DX22 Marine Diagnostic Tool

The DX22 Marine Diagnostic Tool is a cutting-edge solution tailored for professionals in the maritime industry. It enables comprehensive analysis and efficient diagnostics for marine engines, ensuring optimal performance and reliability. This section delves into its key components and unique selling points.

Key Components of the DX22

The design of the DX22 incorporates several integral components that contribute to its effectiveness and user-friendly nature. These key components include:

-

Diagnostic Software

The proprietary software embedded in the DX22 allows for detailed engine analysis, providing technicians with critical insights into engine performance and health. The software is compatible with various Doosan marine engines, making it versatile for different applications.

-

Hardware Interface

The tool features a robust hardware interface that connects seamlessly with marine engine ECUs. This connection is essential for accurate data retrieval and command execution.

-

Display Screen

A bright, easy-to-read display screen provides real-time visuals of diagnostic results, error codes, and system statuses. This immediate access to information enhances the troubleshooting process.

-

Data Logging Capabilities

With advanced data logging capabilities, the DX22 captures essential engine metrics over time. This data is invaluable for trend analysis and long-term maintenance planning.

Unique Selling Points

The DX22 stands out in the market due to several unique selling points that enhance its appeal among marine technicians:

-

Comprehensive Diagnostics

This tool offers in-depth diagnostic functions that surpass basic error code reading, allowing for thorough assessments of marine engine performance.

-

User-Friendly Navigation

The intuitive interface simplifies the navigation process, ensuring that even less experienced technicians can operate the tool effectively.

-

Portability

Designed for the marine environment, the DX22 is lightweight and easily transportable. Its portability makes it ideal for technicians who need to diagnose engines in various locations.

-

Remote Support Features

Integrated remote support through software allows technicians to receive assistance quickly, enhancing the overall user experience and reducing downtime.

-

Frequent Software Updates

The tool benefits from regular software updates that introduce new features and improvements, ensuring it remains at the forefront of marine diagnostic technology.

Compatibility and Support for Marine Engines

Understanding the compatibility and support for marine engines is critical for effective diagnostics and maintenance. The DOOSAN DIAGNOSTIC TOOL DX22 is designed to seamlessly interface with a variety of Doosan marine engines, ensuring reliable performance across different models.

Supported Doosan Marine Engines

The DX22 has been engineered to support a range of Doosan marine engines. These include both current and legacy models, allowing technicians to perform diagnostics on various power units. The primary supported engines encompass:

- Doosan 6D series

- Doosan 8L series

- Doosan DM series

- Doosan DB series

This extensive compatibility allows for efficient service and repair, minimizing the need for multiple diagnostic tools across different engine types. As the technology matures and new models are released, Doosan continues to extend support for its range of engines.

Multi-Model Compatibility

One of the key advantages of the DX22 is its ability to interface with multiple engine models. This multi-model compatibility is vital for marine technicians who face a variety of engines in their daily operations. The diagnostic tool supports simultaneous access to a range of functionalities, including:

- Fault code reading and interpretation

- Parameter monitoring across different engine models

- Component functionality testing

This flexibility not only streamlines the diagnostic process but also enhances the technician’s ability to troubleshoot issues effectively across different units. The DX22 serves as an all-in-one solution, catering to various engine configurations without the necessity for additional equipment.

User-Friendly Interface of the DX22

The User-Friendly Interface of the DX22 enhances the technical experience for users by providing an intuitive layout and accessible features. This makes it easier for technicians to navigate and utilize the tool effectively within marine environments.

Language Settings and Accessibility

The DX22 is equipped with multiple language settings, notably English and Korean. This flexibility allows technicians from different backgrounds to operate the diagnostic tool with ease. The clear and concise labeling of buttons and menus ensures a user-friendly experience regardless of the user’s linguistic proficiency.

In addition to language options, the accessibility features cater to users with diverse needs. Options for font size adjustments and high-contrast modes improve readability and ensure that all users can work efficiently. Such features enhance usability in various lighting conditions, essential for marine operations.

Navigation Simplicity

The interface is designed with simplicity in mind, allowing for seamless navigation between different functions and diagnostic processes. Users can quickly move through the menus with minimal effort, enabling them to focus on their diagnostic tasks rather than struggling with complex controls.

Key aspects of navigation simplicity include:

- Logical Menu Structure: The main menu is organized in a way that intuitively guides users through essential functions, making it easy to locate required features.

- Touchscreen Compatibility: The DX22 supports touchscreen interaction, which simplifies the selection and input of data, making the diagnostic process faster.

- Quick Access Shortcuts: Essential functions can be accessed directly from the main screen, reducing the number of steps required to perform critical tasks.

These elements work together to create a navigation experience that is both productive and satisfactory for users actively engaged in marine engine diagnostics.

Advanced Diagnostic Capabilities

This section explores the sophisticated diagnostic features that the tool offers, enabling precise and detailed analysis of marine engine performance.

Error Code Reading

The ability to read error codes is a vital diagnostic feature that allows technicians to identify specific issues within the engine’s electronic control unit (ECU). When the engine system detects a fault, it generates a unique error code that highlights the problem area.

- Quick Identification: The tool can quickly identify and display error codes, allowing technicians to diagnose issues efficiently.

- Code Storage: The ability to store and recall error codes aids technicians in tracking recurring problems and developing effective solutions.

- Code Descriptions: Each error code comes with detailed descriptions, guiding technicians toward understanding the issue more comprehensively.

Real-Time Data Display

Real-time data display is another powerful aspect of advanced diagnostics. This feature provides continuous updates on various engine parameters, enabling proactive monitoring.

- Live Metrics: Critical metrics such as oil pressure, engine temperature, and RPMs are displayed in real-time, allowing for immediate recognition of abnormalities.

- Graphical Representations: The tool often presents data in visual formats, such as graphs and charts, making it easier to interpret performance trends.

- Historical Data Comparison: Technicians can compare real-time data with historical stats to evaluate changes in engine performance over time.

Critical Engine Metrics

Monitoring critical metrics is essential for ensuring optimal engine performance. This functionality provides insights on:

- Oil Temperature: Tracking oil temperature helps prevent overheating and potential engine damage.

- Fuel Efficiency: Monitoring fuel consumption metrics allows for optimization of engine performance while reducing waste.

- Engine Load: Understanding engine load enables technicians to assess if the engine operates within its designed parameters.

Performance Optimization

In addition to identifying issues, real-time monitoring allows for adjustments that optimize engine performance. By analyzing live data, technicians can make informed decisions that enhance overall engine efficiency.

Component Testing

The DX22 provides functionalities for conducting detailed tests on individual engine components. This feature is instrumental in pinpointing the exact areas needing attention.

- Electrical Component Testing: Check the health of electrical system components, ensuring they operate correctly and safely.

- Mechanical Component Assessment: Identify mechanical issues by testing components such as fuel injectors and sensors.

- Diagnostic Reports: Generate comprehensive reports on the performance of tested components, facilitating thorough evaluations.

Software Update Processes

Keeping software up to date is crucial for maintaining optimal functionality and performance. Regular updates ensure that the tool remains compatible with evolving technologies and introduces new features that enhance user experience.

Frequency of Updates

Software updates for the DX22 diagnostic tool are issued periodically to incorporate improvements and features based on user feedback and technological advancements. The frequency of these updates can vary but typically follows a structured schedule, ensuring that technicians always have access to the latest tools and functionalities. Key aspects include:

- Regularly scheduled updates that align with new engine model releases.

- Prompt updates in response to identified issues or bugs.

- Scheduled maintenance updates aimed at improving overall performance and usability.

By implementing frequent updates, the tool ensures it stays equipped to handle the latest demands of marine engine diagnostics.

New Features in Latest Versions

Each software update not only addresses bugs and fixes but also introduces new functionalities that can significantly improve diagnostic capabilities. Recent updates have included:

- Enhanced User Interface: Improvements in the layout and navigation make it even easier for technicians to access vital information quickly.

- Expanded Diagnostic Functions: New algorithms for error code readings help in identifying issues with greater accuracy.

- Increased Compatibility: Updates ensure that the DX22 continues to support the latest models of Doosan marine engines.

- Performance Metrics Enhancement: New features allow for a more detailed realtime display of critical engine data, contributing to better diagnostics and monitoring.

These enhancements demonstrate the commitment to providing a robust and efficient diagnostic tool. Regular access to the latest features allows technicians to continually refine their skills and improve the maintenance procedures for marine engines.

Portability and Design for Marine Environments

The DOOSAN DIAGNOSTIC TOOL DX22 is meticulously engineered to thrive in challenging marine settings. Its portability and robust design ensure reliable functionality, making it an indispensable tool for maritime technicians.

Lightweight Features

One of the standout attributes of the DX22 is its lightweight construction. Weighing considerably less than many traditional diagnostic tools, it is designed for ease of use in compact spaces, such as engine rooms and on deck. This characteristic facilitates efficient handling, allowing technicians to maneuver the device with minimal effort.

The lightweight nature of the DX22 also enhances its portability. Technicians often require diagnostic tools that can be easily transported between locations. The DX22 meets this need, offering a compact alternative that easily fits into standard tool bags without adding excessive weight.

Durability in Harsh Conditions

Durability is a critical consideration for tools used in marine environments. The DX22 is constructed with high-quality materials that can withstand the rigors of maritime use, including exposure to saltwater, moisture, and fluctuating temperatures. This resilience ensures that the device maintains its integrity and functionality over time, even in the face of challenging conditions.

Furthermore, the design of the DX22 includes protective features that help guard against mechanical shocks and vibrations, which are common in marine operations. These enhancements reduce the risk of damage during transport or use, ultimately extending the life of the tool and maximizing its return on investment.

Installation and Configuration

The installation and configuration of the diagnostic tool are crucial steps that ensure the device functions optimally. Proper setup helps maintain efficiency and expands the usability of the device in various marine environments.

System Requirements

To successfully install the diagnostic tool, specific system requirements must be met. These requirements ensure that the software runs smoothly and efficiently on the intended hardware. The key system specifications are:

- Operating System: Windows 10 (64-bit) or Windows 11 (64-bit)

- Processor: Minimum Intel i3 or equivalent

- RAM: At least 4 GB for optimal performance

- Hard Disk Space: 300 MB of available space for installation

- USB Port: Required for connecting the diagnostic tool

Ensuring that these specifications are met can help avoid complications during installation and improve the overall user experience.

Step-by-Step Installation Guide

The process of installing the diagnostic tool is straightforward, allowing users to set it up efficiently. Below is a detailed, step-by-step guide outlining the installation process:

- Download the Software: Access the official Doosan website or authorized sources to download the latest version of the diagnostic tool software.

- Locate the Installation File: After downloading, navigate to the folder where the installation file is saved. The file will typically be named DoosanDX22Setup.exe.

- Run the Installation: Double-click on the installation file. A setup wizard will appear, guiding through the process. Follow the prompts to proceed.

- Accept the License Agreement: Read through the license agreement and accept the terms to continue with the installation.

- Choose Installation Location: Select a directory on the hard drive where the software will be installed. The default location is usually sufficient for most users.

- Complete the Installation: Click ‘Install’ to start the installation process. Wait until all files are copied and the installation is complete.

- Activate the Software: Upon completion, a prompt to enter the activation key will appear. Input the key provided with the purchase to unlock all features of the software.

- Connect the Diagnostic Tool: Use the appropriate USB cable to connect the diagnostic tool to the computer. Ensure the device is powered on.

- Launch the Software: Open the installed software from the desktop or the start menu. The tool should automatically detect the connected device.

Following these steps carefully will ensure that the diagnostic tool is set up correctly, facilitating optimal performance and functionality.

Key Features of the DX22 Diagnostic Tool

The DX22 Diagnostic Tool boasts several advanced features essential for effective marine engine diagnostics. These capabilities enhance the overall performance, reliability, and efficiency in maintaining marine engines.

Error Code Scanning

Error code scanning is one of the most vital features of the DX22 tool. This function allows technicians to efficiently identify any issues within the engine’s electronic control unit (ECU). When a malfunction occurs, the system generates specific codes that indicate where problems may lie.

By accessing these codes, technicians can:

- Quickly pinpoint the source of malfunctions.

- Track recurring issues for better maintenance planning.

- Record error codes for future reference, aiding in more accurate diagnostics.

Real-Time Monitoring

Real-time data monitoring is another core capability of the DX22. This feature enables technicians to view critical operational parameters while the engine is running, significantly enhancing the diagnostic process.

Critical Engine Metrics

Technicians can monitor various critical metrics, which include:

- Engine temperature: Helps prevent overheating issues.

- Oil pressure: Essential for maintaining lubrication and preventing engine wear.

- Fuel consumption: Aids in assessing efficiency and performance levels.

By constantly monitoring these metrics, technicians can identify potential issues before they escalate, ensuring the engine remains in optimal condition.

Performance Optimization

Real-time insights enable fine-tuning of the engine’s performance. By adjusting operational parameters based on data received, technicians can:

- Enhance fuel efficiency.

- Improve power output.

- Reduce emissions, contributing to a cleaner operation.

Component Testing

The DX22 also provides advanced component testing capabilities. This functionality allows technicians to conduct specific tests on various engine components and systems, confirming their operational integrity.

Through component testing, the tool enables the assessment of:

- Electrical systems: Ensuring all electrical connections function correctly.

- Fuel injectors: Verifying spray patterns and fuel delivery.

- Ignition systems: Checking spark plug performance and ignition timing.

These tests help ensure that each part of the engine is functioning as intended, which is crucial for maintaining the overall health and efficiency of marine engines.

Benefits of Using the DX22 for Marine Engine Maintenance

The DOOSAN DIAGNOSTIC TOOL DX22 brings several advantages that significantly enhance marine engine maintenance. Its features optimize diagnostics, reduce costs, and improve safety, making it an indispensable tool for marine technicians.

Efficiency in Diagnostics

The DX22 streamlines the diagnostic process, allowing technicians to quickly identify issues affecting engine performance. This efficiency translates to faster resolutions and minimal downtime.

- Rapid error code identification enhances troubleshooting speed and accuracy.

- Real-time data monitoring provides immediate insights into engine conditions.

- Component testing capabilities eliminate guesswork, ensuring precise diagnostics.

Cost Reduction

Utilizing the DX22 can lead to significant cost savings in marine engine maintenance through proactive issues management and efficient resource allocation.

Preventing Major Failures

By enabling timely diagnostics, the DX22 helps prevent catastrophic failures that could result in extensive repairs.

- Regular monitoring allows for the detection of early warning signs of wear or malfunction.

- Effective identification of problems can avoid costly emergency interventions.

Minimizing Repair Costs

The tool’s comprehensive diagnostic capabilities facilitate accurate repairs, minimizing unnecessary expenditures.

- Clear error codes inform technicians about specific problems, reducing the trial-and-error approach.

- Informed decision-making based on real-time data can optimize repair strategies and resources.

Enhancing Safety

Safety is a top priority in marine operations, and the DX22 contributes significantly to ensuring that all systems function within safe parameters.

- Accurate diagnostics reduce the risks associated with operating faulty equipment.

- Regular checks and proactive maintenance enhance the overall safety of marine environments.

- The tool aids in compliance with safety regulations by ensuring that all marine systems are operating correctly.

Technician Training and Support

Effective training and robust support are essential for technicians using the diagnostic tools in marine engines. This section highlights the ease of use of the DX22 tool and the additional support options available to ensure technicians are well-equipped to handle their tasks.

Ease of Use

The DOOSAN DIAGNOSTIC TOOL DX22 is crafted with user-friendliness in mind. The intuitive interface allows technicians, regardless of their experience level, to navigate through its functionalities effortlessly. Key aspects contributing to its ease of use include:

- Intuitive Design: The layout of the software is logical and straightforward, minimizing the learning curve for new users.

- Comprehensive User Manuals: Detailed guides accompany the tool, providing step-by-step instructions that enhance the learning experience.

- Interactive Tutorials: Technicians can access video tutorials that visually demonstrate features and functionalities.

- Responsive Interface: The software adapts quickly to user inputs, providing a smooth experience during diagnostics.

Remote Installation Support via TeamViewer

Ensuring that the DX22 software is setup and running smoothly is a priority for effective diagnostics. Remote support options are available to technicians, providing convenience and efficiency.

- Real-Time Assistance: Technicians can connect with support staff via TeamViewer, allowing for immediate troubleshooting and setup guidance.

- Step-by-Step Installation: During remote sessions, support personnel guide technicians through the initial installation process, ensuring that all necessary configurations are correctly set up.

- Access to Expert Knowledge: Support teams can share screens and demonstrate features, greatly enhancing the learning experience.

- Time Efficiency: Remote assistance helps technicians resolve issues quickly without needing to wait for onsite support, reducing downtime significantly.

Enhancing Maintenance Efficiency with the DX22

The DX22 plays a pivotal role in improving maintenance efficiency for marine engines. It achieves this through its streamlined diagnostics and significant reduction in downtime.

Streamlined Diagnostics

One of the primary advantages of the DX22 is its capability to facilitate uncomplicated and accurate diagnostics. This tool simplifies the diagnostic process in several ways:

- Comprehensive error code reading enables quick identification of issues.

- Real-time data monitoring allows technicians to observe critical engine metrics as they work.

- The intuitive interface provides seamless navigation, making it easier to access diagnostic features.

These attributes significantly enhance the efficiency with which technicians can pinpoint problems, enabling faster interventions and reducing the time taken to address mechanical failures. By quickly diagnosing issues, users can initiate repairs sooner, resulting in a more efficient workflow.

Reducing Downtime

Minimizing downtime is crucial in marine environments where operational efficiency is paramount. The DX22 assists in this regard by:

- Enabling preventive maintenance through early detection of potential problems.

- Providing timely updates and software enhancements that improve diagnostic capabilities.

- Permitting remote diagnostic support via tools like TeamViewer, allowing for rapid response from experts.

By reducing the amount of time engines are out of service, the DX22 helps to optimize scheduling and resource allocation for maintenance activities. This efficiency translates into improved productivity, ensuring that vessels are available for operations with minimal interruptions.

Real-Time Performance Monitoring

Real-time performance monitoring is crucial for ensuring optimal operation of marine engines. This functionality allows technicians to track vital engine metrics and address issues as they arise, thereby enhancing overall operational efficiency.

Benefits for Technicians

Real-time performance monitoring provides numerous advantages for technicians working on marine engines. With instant access to crucial metrics, they can:

- Quickly identify irregularities in engine performance.

- Diagnose issues more effectively using live data rather than relying on historical information.

- Make informed decisions to rectify faults before they escalate into significant problems.

- Enhance their diagnostic skills by observing live trends and patterns in engine behavior.

This real-time insight leads to quicker turnaround times for repairs and improved reliability of the machinery.

Optimizing Engine Performance

Maintaining peak performance in marine engines is crucial for operational efficiency and longevity. Real-time performance monitoring plays a significant role in this process in several ways:

- Continuous monitoring of critical engine metrics such as temperature, pressure, and RPM allows for proactive management of engine conditions.

- Data-driven insights enable the adjustment of operational parameters to enhance fuel efficiency and reduce wear and tear on engine components.

- Identifying trends over time provides valuable knowledge that can inform maintenance schedules and operational practices.

By utilizing real-time data, operators can ensure their vessels perform at optimal levels, thus enhancing safety and minimizing downtime.

Software updates and enhancements play a vital role in maintaining the functionality and performance of diagnostic tools. Timely updates ensure users have access to the latest features, compatibility improvements, and bug fixes. These updates can significantly affect the efficiency and accuracy of diagnostics in marine environments.

Software Updates and Enhancements

Importance of Updates

Regular software updates are crucial for several reasons:

- Enhancements to Diagnostic Functions: Updates may introduce new diagnostic features and tools that improve the user’s ability to detect and analyze issues within marine engines.

- Increased Compatibility: Keeping the software updated ensures that the diagnostic tool remains compatible with the latest models of Doosan marine engines, as well as any modifications made to existing engines.

- Bug Fixes: Software updates often address previously identified bugs and technical issues, ensuring smoother operation and reliability of the diagnostic tool.

- Security Improvements: Updates can include security patches that protect the tool from vulnerabilities, ensuring safe operation in various environments.

Accessing New Features

To benefit from the enhancements provided by software updates, users must follow specific procedures to access new features:

- Regular Check for Updates: Users should routinely check for available updates through the software interface. This can usually be done with a simple command that scans for updates.

- Utilizing the Update Function: The DOOSAN DIAGNOSTIC TOOL DX22 includes a user-friendly update option that allows technicians to download and install updates directly from the software interface.

- Remote Support Option: In certain cases, users may engage remote support through TeamViewer to assist in troubleshooting any issues that arise during the update process.

- Installing Updates: Once downloaded, updates need to be installed, requiring a brief period of downtime for the tool. The installation process typically follows a straightforward step-by-step guide presented within the software.

Comparing the DX22 with Other Diagnostic Tools

In the competitive landscape of marine diagnostic tools, it is essential to evaluate how the DX22 stands out against its rivals. This section delves into the strengths of the DX22 and provides a comprehensive analysis of its competitors.

Strengths of the DX22

The DX22 possesses several notable strengths that differentiate it from other diagnostic tools available in the market:

- Specialization: Unlike many diagnostic tools that serve a broad range of machinery, the DX22 is specifically designed for Doosan marine engines, ensuring a tailored approach to diagnostics.

- User-Friendly Interface: The intuitive graphical interface simplifies navigation for technicians, regardless of their expertise. This contributes to a quicker diagnosis process.

- Real-Time Monitoring: The ability to display real-time data allows for immediate assessment of engine performance, enabling proactive maintenance actions.

- Error Code Reading: Advanced capabilities in reading and interpreting error codes facilitate effective troubleshooting and maintenance strategies.

- Regular Software Updates: The commitment to frequent updates means that users benefit from the latest enhancements and features, keeping the tool relevant in a rapidly evolving industry.

Competitor Analysis

While assessing the DX22, it is crucial to consider how it compares to other diagnostic tools on the market. Key competitors vary in their offerings and specializations:

- Brand A: Known for multifunctionality, Brand A tools offer capabilities across various machinery types. However, their lack of specialization for specific engine types can lead to inefficiencies in diagnosing marine engines.

- Brand B: This tool emphasizes a wide language support and user customization. While versatile, it may sacrifice depth in diagnostic functionalities specific to marine engineering.

- Brand C: Specializes in heavy-duty diesel engines, but often lacks features aimed explicitly at marine applications, making it less suitable for marine technicians.

- Brand D: Offers an array of features but at a higher price point. The cost may not justify the additional functionalities when compared with the DX22’s specialized offerings.

Overall, the DX22 shines in its dedicated approach to Doosan marine engines, providing a unique value proposition that is difficult to match among its competitors. Its cutting-edge features and support ensure that it remains a top choice for marine diagnostics in 2024.

Improving Safety with Accurate Diagnostics

Accurate diagnostics play a pivotal role in enhancing safety within marine operations. By identifying potential issues before they escalate, the risks associated with engine failures and other malfunctions can be significantly reduced.

Identifying Potential Issues

The early detection of potential problems is crucial to ensuring the longevity and reliability of marine engines. Utilizing advanced diagnostic tools allows technicians to systematically evaluate engine performance and pinpoint issues that may not be immediately apparent. Key aspects of identifying potential issues include:

- Error Code Analysis: Reading and interpreting error codes from the engine’s ECU helps in diagnosing faults efficiently.

- Real-Time Monitoring: Observing engine parameters in real-time can reveal fluctuations that indicate potential failures.

- Systematic Component Testing: Running diagnostic tests on individual components provides insights into their operational status.

- Historical Data Comparison: Comparing current performance metrics with historical data allows for the identification of trends that may signal impending issues.

By employing these strategies, technicians can address concerns proactively, ensuring the safety of both the vessel and crew members onboard.

Ensuring Safe Operations

Establishing and maintaining safe operational practices in marine environments is essential for preventing accidents and ensuring the well-being of all personnel involved. Accurate diagnostics contribute to safe operations through the following mechanisms:

- Proactive Maintenance Scheduling: Regular diagnostics enable the scheduling of preventive maintenance, reducing the likelihood of sudden failures.

- Enhanced Safety Protocols: Incorporating diagnostic data into safety protocols allows for informed decision-making and risk management.

- Improved Training for Technicians: Understanding diagnostic capabilities empowers technicians with the knowledge necessary to identify and resolve issues quickly.

- Failure Mode Analysis: Analyzing potential failure modes based on diagnostic information can lead to the development of contingency plans.

Integrating these practices fosters an environment of safety and reliability, crucial for the operation of marine vessels in challenging conditions.

Cost Efficiency in Marine Engine Maintenance

Cost efficiency in marine engine maintenance involves strategies and tools that minimize expenses while maximizing performance and reliability. By adopting effective diagnostic solutions, operators can achieve significant savings and reduce operational risks.

Long-Term Savings

Utilizing advanced diagnostic tools contributes to long-term savings in several ways. Regular maintenance sponsored by accurate diagnostics allows for the timely identification of issues, which in turn mitigates costly repairs and unexpected breakdowns. Proactive maintenance not only extends the lifespan of marine engines but also enhances their overall operational efficiency.

Some key aspects of achieving long-term savings include:

- Preventative Maintenance: Scheduled service interventions based on diagnostic insights prevent minor issues from escalating into major failures.

- Fuel Efficiency: Properly maintained engines operate at optimal efficiency, leading to reduced fuel consumption and lower operational costs.

- Reduced Downtime: Swift identification and resolution of issues ensure that vessels spend less time out of service, thus maintaining productivity and revenue generation.

Budget-Friendly Diagnostics

Integrating budget-friendly diagnostic tools aids maritime professionals in managing their maintenance expenses effectively. Affordable diagnostic solutions combined with high-quality performance facilitate informed decision-making regarding equipment maintenance and repairs.

Budget-friendly diagnostics contribute to cost efficiency through:

- Cost-Effective Troubleshooting: Rapid error code reading and analysis reduce the time and resources spent on diagnostics, allowing for quicker repairs.

- Access to Updates: Regular software updates ensure the diagnostic tool remains capable of addressing the most recent engine technology changes without additional costs.

- Training and Support: User-friendly interfaces and remote installation support reduce training costs for technicians, allowing for smoother operations with minimal investment.

Maximizing Engine Life Span with the DX22

The DOOSAN DIAGNOSTIC TOOL DX22 plays a crucial role in extending the lifespan of marine engines through effective management and analysis. Implementing preventive maintenance ensures engines operate at peak performance and remain functional for years to come.

Preventive Maintenance

Implementing a preventive maintenance strategy is essential for protecting marine engines from unanticipated failures. Utilizing the DX22 allows technicians to perform thorough diagnostics and regular checks that prevent significant breakdowns.

- Regular diagnostics can identify potential issues before they escalate.

- Error code scanning aids in recognizing malfunctions early.

- Real-time data monitoring can track performance trends and flag anomalies.

- Routine component testing ensures each part functions correctly.

By maintaining a schedule for these diagnostic checks, operators can keep their engines running smoothly and efficiently, thus avoiding costly repairs and minimizing downtime. Comprehensive reports generated by the DX22 support informed decision-making about maintenance needs.

Enhancing Engine Longevity

Longevity of marine engines can significantly determine operational costs and performance reliability. With the DX22, various strategies can be implemented to prolong engine life.

- Preventive measures based on diagnostic results help mitigate wear and tear.

- Monitoring critical engine metrics ensures components remain within safe operating limits.

- Adjustments suggested by the DX22 can optimize engine performance and efficiency.

These measures not only enhance performance but also contribute to fuel efficiency, ultimately leading to lower operational costs. Furthermore, ensuring thorough training for technicians on utilizing the DX22 effectively ensures that all diagnostic opportunities are maximized for the best maintenance practices.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

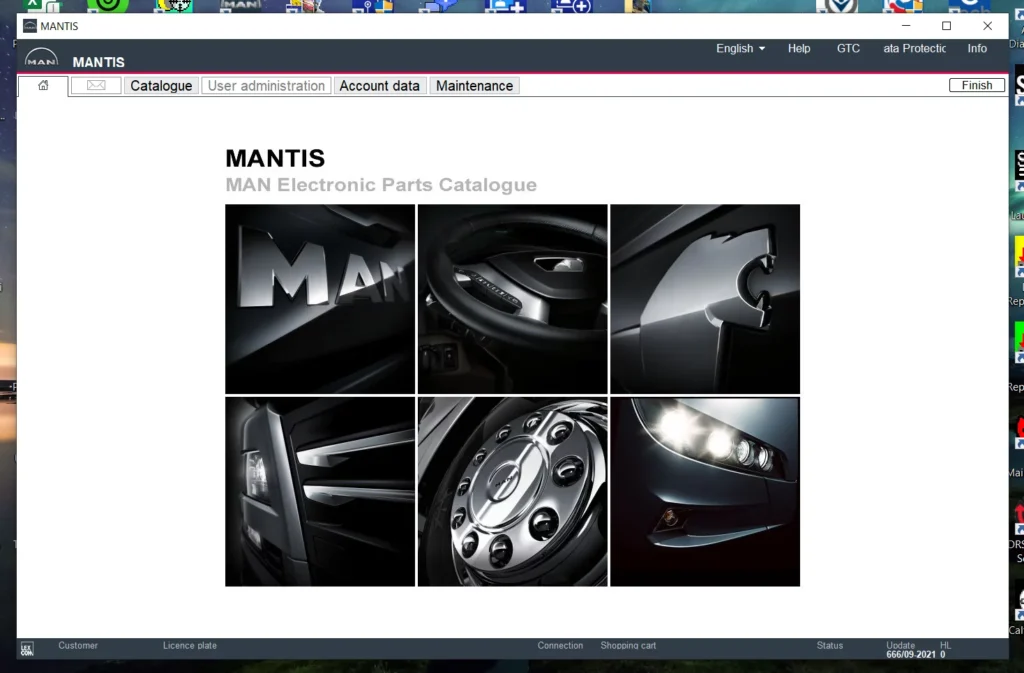

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.