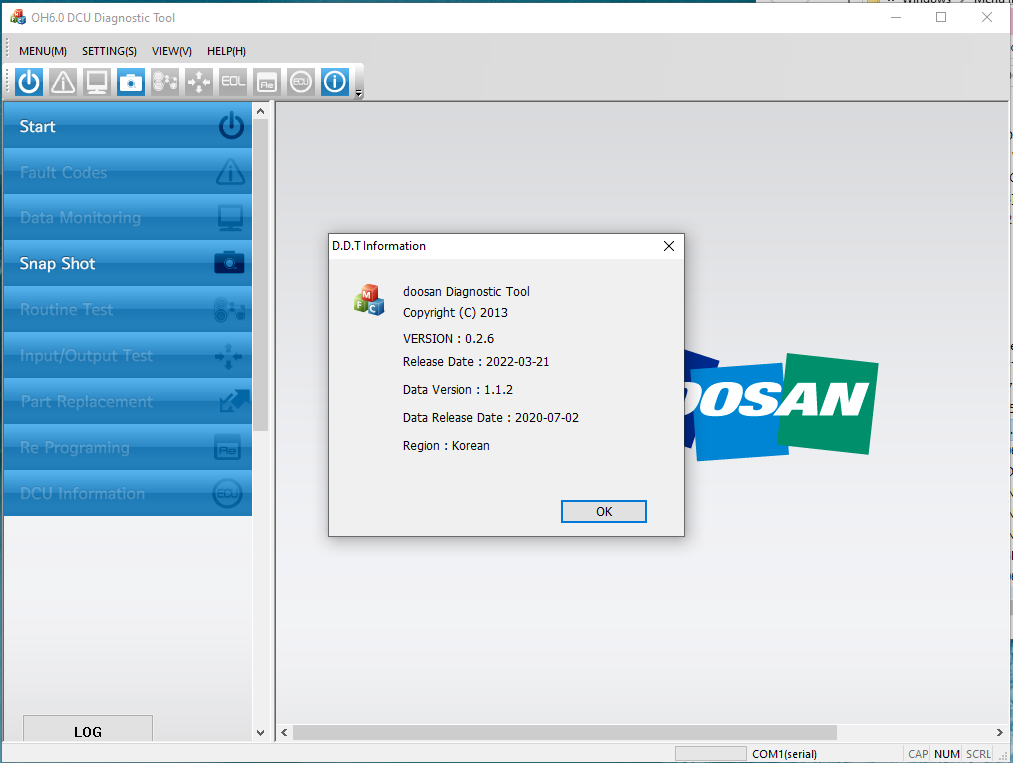

DOOSAN DIAGNOSTIC OH6.0 2022 : Your Essential Tool for Heavy Equipment Management

The DOOSAN DIAGNOSTIC OH6.0 2022 is an essential software for managing Doosan heavy equipment. Released in 2022, it offers various features designed to enhance diagnostic capabilities across multiple engine models. This tool supports efficient troubleshooting and maintenance, ensuring optimal performance for users. Its compatibility with Windows and user-friendly interface makes it accessible for technicians and operators, facilitating smooth operation in the field.

Overview of Doosan Diagnostic Tool OH6.0

The Doosan Diagnostic Tool OH6.0 is a cutting-edge solution designed for effective management and diagnostics of Doosan heavy equipment. It has been developed to enhance operational efficiency and troubleshooting capabilities for various engines used in construction machinery.

Brief History and Development

The Doosan Diagnostic Tool OH6.0 was launched in 2022, reflecting Doosan’s commitment to advancing technology in the heavy machinery sector. This tool was designed as part of a broader strategy to provide integrated diagnostic solutions that cater to a wide range of Doosan equipment. Over the years, Doosan has invested in research and development to ensure that its diagnostic tools meet the evolving needs of technicians and operators.

The tool’s evolution has been marked by the introduction of significant updates, including version 1.0.8 released in March 2022, which incorporated user feedback to improve functionality and ease of use. This continuous improvement cycle demonstrates Doosan’s dedication to offering innovative solutions that address the challenges faced in the field.

Key Features and Specifications

The Doosan Diagnostic Tool OH6.0 boasts a variety of features that enhance its utility for heavy equipment diagnostics. Key specifications include:

- Compatibility with multiple Doosan engine models, which include:

- DL06

- DL08

- DV11

- DV11S

- Robust diagnostic capabilities for a comprehensive analysis of engine performance.

- An easy-to-navigate interface that simplifies the user experience while performing diagnostics and troubleshooting.

- Support for various operating systems, primarily optimized for Windows environments.

- Multi-language support enhancing accessibility for users in different regions, with particular emphasis on English and Korean.

These features collectively contribute to the effectiveness of the tool, making it an essential component of maintenance routines within organizations that rely on Doosan machinery.

System Requirements

Understanding the system requirements is crucial for optimal performance. The Doosan Diagnostic Tool OH6.0 functions best when used on compatible systems that meet specific technical criteria.

Compatible Operating Systems

Windows Compatibility

The Doosan Diagnostic Tool OH6.0 is specifically designed to work with Windows operating systems. It is compatible with:

- Windows 7 x32

Using this operating system ensures smooth communication between the software and Doosan equipment. Users should ensure that their system is updated and configured correctly to take full advantage of the diagnostic features.

Other System Requirements

Beyond the operating system, there are additional requirements for the effective installation and operation of the tool. These include:

- Processor: A minimum of 1 GHz processor speed

- RAM: At least 2 GB of RAM for optimal performance

- USB Ports: At least one available USB port to connect diagnostic hardware

By ensuring these requirements are met, users can prevent potential issues during installation and function, leading to a more seamless experience.

Space and Installation Requirements

Users should be aware of the necessary disk space and installation conditions required for the Doosan Diagnostic Tool OH6.0.

Disk Space Requirements

The tool requires the following disk space:

- 292 MB of free disk space after installation

- 126 MB for the initial installation file

Ensuring adequate space is available will help in running the software efficiently without any interruptions.

Installation Process

The installation process involves downloading the software and following a few straightforward steps. It is advisable to have administrative rights on the PC to facilitate the installation process. A stable internet connection is recommended for downloading updates or additional components during installation.

Supported Equipment and Engines

The Doosan Diagnostic Tool OH6.0 is designed to work seamlessly with a variety of engines and heavy machinery. It ensures effective diagnostics and maintenance for a wide range of Doosan equipment.

List of Compatible Engines

DL06

The DL06 engine is known for its durability and performance in various heavy machinery applications. It is commonly used in construction equipment, offering reliable power and efficiency.

DL08

DL08 engines are designed for larger machinery, providing enhanced torque and horsepower. They are often favored in applications that require significant lifting and hauling capabilities.

DV11

The DV11 engine is a powerful option for heavy-duty machinery, recognized for its fuel efficiency and low emissions. It is ideal for operators seeking to balance performance with environmental concerns.

DV11S

DV11S engines are optimized for special applications, ensuring adaptability across various equipment types. Their design incorporates advanced technology for improved diagnostics and maintenance.

Types of Heavy Equipment Supported

The tool supports a wide range of Doosan heavy equipment, facilitating effective diagnostics across numerous model types. This versatility is critical for operators managing multiple machines or fleets.

- Excavators: Designed for digging and earth-moving tasks, these machines benefit significantly from regular diagnostic checks.

- Loaders: Essential for lifting and transporting materials, loaders rely on engine performance for efficiency and productivity.

- Dozers: Used for pushing large amounts of soil, these machines require dependable engines, which can be monitored through diagnostics.

- Forklifts: Widely used in warehouses and construction sites, their operational efficiency can be enhanced with accurate engine diagnostics.

- Crane Trucks: These vehicles need precise engine performance for safe and effective lifting capabilities.

Language and Accessibility Options

The Doosan Diagnostic Tool OH6.0 offers a variety of language settings and accessibility options, allowing users from different regions and backgrounds to effectively utilize the software. This inclusivity ensures that operators and technicians can navigate the tool with ease, enhancing their overall experience.

Available Languages

This diagnostic tool supports multiple languages to cater to a global audience. The primary languages available are:

Korean Language Support

The inclusion of Korean language support is particularly beneficial for users in South Korea and regions with a significant Korean-speaking population. All interface elements, help documentation, and support materials are available in Korean. This feature enhances usability and ensures that native speakers can fully engage with the software without language barriers.

English Language Support

English language support is also provided, ensuring that users in English-speaking countries have a seamless experience. The interface, guides, and technical support are all available in English. This accessibility meets the needs of a wide array of technicians and equipment operators who prefer to work in English.

Regional Accessibility

The Doosan Diagnostic Tool OH6.0 is designed to be accessible regardless of the user’s location. The software’s compatibility with various operating systems and its lightweight requirements contribute to its widespread usability.

Users can access the diagnostic tool easily, whether in urban centers or remote areas, provided they have the necessary hardware and internet connectivity. This flexibility allows technicians working on construction sites or in less populated regions to rely on the software for effective diagnostics.

Diagnostic Capabilities

The Doosan Diagnostic Tool OH6.0 is equipped with comprehensive diagnostic capabilities that enhance the maintenance and operation of Doosan equipment. Its state-of-the-art features facilitate precise problem identification and ensure optimal performance of heavy machinery.

Key Diagnostic Functions

The key diagnostic functions of the Doosan Diagnostic Tool OH6.0 enable technicians to swiftly assess the status and performance of various engine components. These functions include:

- Real-Time Monitoring: This function allows for live tracking of engine parameters, providing insights into performance metrics such as RPM, temperature, and pressure.

- Error Code Retrieval: The tool can extract and display fault codes directly from the engine control unit (ECU), aiding in quick diagnostics and troubleshooting.

- Sensor Testing: Technicians can utilize sensor testing capabilities to verify the functionality of critical sensors that affect engine performance and safety.

- System Diagnostics: This feature runs a comprehensive check on various systems within the machinery, identifying potential issues before they escalate.

Diagnostic Modes

The Doosan Diagnostic Tool OH6.0 operates in multiple diagnostic modes, each tailored to specific diagnostic needs and complexity levels. These modes ensure flexibility and precise targeting during troubleshooting.

Standard Mode

The Standard Mode is designed for general diagnostics and is user-friendly for everyday maintenance tasks. Key attributes include:

- Basic Inspections: Allows operators to conduct routine checks on engine functions without advanced technical knowledge.

- Quick Error Lookup: Provides immediate access to common error codes and suggested solutions, streamlining the troubleshooting process.

- Performance Monitoring: Facilitates monitoring of essential operational parameters to maintain optimal performance levels.

Advanced Mode

The Advanced Mode offers in-depth diagnostics for experienced technicians needing detailed analysis. Features of this mode include:

- Comprehensive Diagnostic Tests: Enables extensive testing of all engine systems and components to uncover less obvious issues.

- Data Logging: The capability to log performance data over time allows for deeper insights into operational patterns and potential failures.

- Customized Testing Procedures: Technicians can set up specific testing scenarios tailored to individual equipment needs, enhancing diagnostic accuracy.

Installation and Configuration

The installation and configuration process for the Doosan Diagnostic Tool OH6.0 is designed to be straightforward and user-friendly, ensuring that users can set up the software efficiently for optimal performance. This section outlines the steps required for installation and how to correctly configure the software for use.

Step-by-Step Installation Guide

Initial Setup

To begin the initial setup of the Doosan Diagnostic Tool OH6.0, follow these steps:

- Download the software installation file from an authorized source.

- Locate the downloaded file and double-click to start the installation process.

- Follow the on-screen prompts to proceed with the installation.

- Accept the licensing agreement and select the destination folder for the installation.

- Click “Install” and wait for the process to complete. This may take several minutes.

- Once installation is finished, you will see a confirmation message on the screen.

Configuration Settings

After installation, configuring the software is essential for its effective operation. The following steps should be taken to ensure proper setup:

- Launch the Doosan Diagnostic Tool from the desktop shortcut created during installation.

- Access the settings menu through the toolbar, where various configuration options can be adjusted.

- Select the compatible engine model from the provided list to tailor the diagnostic functions accordingly.

- Adjust preferences such as language settings—options may include Korean and English—to fit user requirements.

- Save the changes made in the configuration settings before exiting the menu.

Using Keygen for Activation

The activation process for the Doosan Diagnostic Tool requires the use of a keygen. This allows the software to function without limitations, providing full access to all diagnostic capabilities.

Unlocked Version

The unlocked version of the Doosan Diagnostic Tool offers the full suite of features without restrictions. The activation using the keygen should be executed as follows:

- Open the keygen application that was included with the software package.

- Input the installation ID generated during the initial setup.

- Click the “Generate Key” button, which will create an activation key.

- Copy the generated key and return to the diagnostic tool software.

- Paste the key into the activation field and confirm to unlock all features.

Locked Version

The locked version requires additional steps to ensure proper activation. For this process:

- Repeat the initial key generation process using the keygen.

- Enter the generated key into the locked version activation prompt of the software.

- This version may have limited access to certain features until the activation process is fully completed.

Remote Installation Services

Remote installation services provide essential support for users, ensuring efficient setup and configuration of the Doosan Diagnostic Tool OH6.0. Through remote assistance, technicians can guide operators through the installation process, minimizing downtime and enhancing user experience.

Support via ecmtrucks.com

ecmtrucks.com offers dedicated support for remote installation services. This platform specializes in facilitating the installation process, providing users with expert assistance at their convenience. With the help of skilled technicians, users can complete their installations smoothly without the need for physical presence.

TeamViewer Remote Assistance

TeamViewer is a powerful tool that allows technicians to remotely assist users in the installation and configuration of the diagnostic software. This capability ensures that help is just a click away, simplifying the setup process significantly.

How to Use TeamViewer

Using TeamViewer is straightforward. After downloading and installing the application, users can share their session ID and password with the technician, granting them temporary access to their computer. This access allows the technician to perform necessary installations and troubleshoot any issues that may arise during the process.

- Download and install TeamViewer from the official website.

- Launch the application and note the session ID and password.

- Provide the session details to the technician for remote access.

- Engage in real-time assistance as the technician guides through the installation.

Scheduling Remote Installations

Arranging remote installations through ecmtrucks.com is efficient. Users can choose convenient time slots, allowing for minimal disruption to their operations.

- Visit the ecmtrucks.com website to access the scheduling tool.

- Select an available time that fits the operational schedule.

- Confirm the appointment and receive a confirmation email detailing the session information.

- Prepare the system for remote access at the scheduled time.

Comparison with Competitor Tools

The competitive landscape for diagnostic tools in heavy equipment has gained significant attention in recent years. Understanding how the Doosan Diagnostic Tool OH6.0 stacks up against other options in the market is essential for making informed decisions.

ecmtrucks.com vs JCB Servicemaster

The ecmtrucks.com diagnostic tool offers a robust solution tailored specifically for a wide range of heavy machinery, including Doosan models. It is often compared with JCB Servicemaster, known for its advanced features but higher price point.

- Cost-Effectiveness:ecmtrucks.com provides a more affordable option without compromising on essential diagnostic features, making it suitable for businesses of all sizes.

- Feature Set:While JCB Servicemaster includes premium features targeting specific machinery, ecmtrucks.com maintains a comprehensive suite that is inclusive for various models, ideal for mixed fleets.

- User Experience:The interface of ecmtrucks.com is designed for ease of use, offering seamless navigation and quicker diagnosis, while JCB may present a steeper learning curve for new users.

Comparing to CNH EST and Other Tools

The comparison with CNH EST and similar diagnostic tools reveals several distinctive aspects that enhance the choice for technicians and fleet managers.

- Compatibility:ecmtrucks.com shows extensive compatibility with various Doosan engines, whereas CNH EST is more focused on a specific category of equipment.

- Performance:In head-to-head assessments, ecmtrucks.com demonstrates faster diagnostic capabilities, significantly reducing downtime during maintenance procedures compared to CNH EST.

- Support and Updates:ecmtrucks.com aims to keep its users informed with regular software updates and provides strong customer support that rivals CNH EST, ensuring users have reliable assistance at hand.

Regular maintenance and updates are crucial for ensuring optimal performance and longevity of diagnostic tools. Keeping software up to date not only enhances functionality but also mitigates potential issues that may arise during operation.

Regular Maintenance and Updates

Importance of Regular Updates

Regular updates serve multiple purposes in maintaining the efficiency of diagnostic tools. They include:

- Enhancing software performance by integrating the latest features.

- Fixing bugs and vulnerabilities to ensure security.

- Improving compatibility with newer heavy equipment models.

- Providing access to updated diagnostic libraries for more accurate troubleshooting.

By ensuring these updates are conducted frequently, users can minimize the risk of downtime and operational failures during critical tasks.

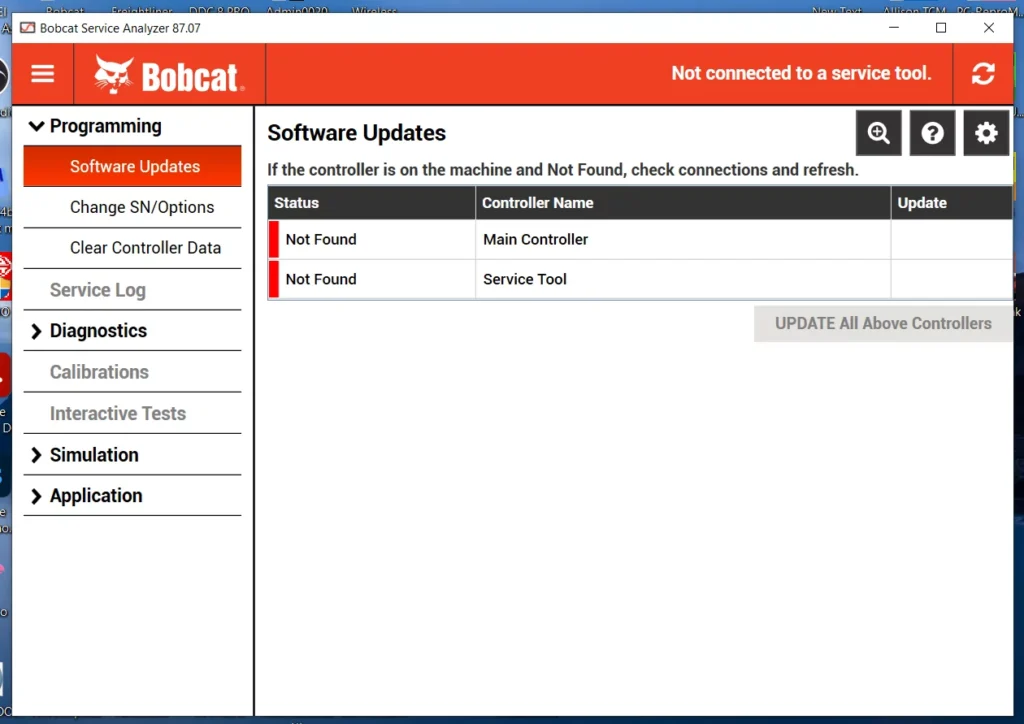

How to Update Your Diagnostic Tool

Updating the diagnostic tool is a straightforward process that can be completed in a few steps, ensuring users have the most current version available.

Step-by-Step Update Process

- Access the official website or software platform where the diagnostic tool was purchased.

- Log into your user account to track available updates.

- Download the latest version of the software.

- Follow the installation prompts to integrate the new update into your existing system.

- Restart the software to ensure all changes take effect.

Common Update Issues and Solutions

While updating, users may encounter certain challenges. It is essential to know how to address these common issues:

- Failed Installations: Ensure the system meets all requirements and has sufficient space for installation.

- Incompatibility Messages: Verify that the operating system is supported and check for additional software updates.

- Slow Performance Post-Update: Clear cache and unnecessary files to optimize the system’s speed.

Addressing these issues promptly will maintain the reliability of the tool.

Proactive Equipment Maintenance

Beyond software updates, proactive equipment maintenance ensures diagnostic tools function at peak efficiency.

- Conduct regular checks on all compatible equipment to identify issues early.

- Ensure all connections and interfaces are secure and functioning properly.

- Schedule periodic training for users to stay informed about new features and best practices.

This proactive approach not only minimizes downtime but also maximizes productivity in equipment operations.

Troubleshooting Common Issues

Troubleshooting common issues is essential to ensure the smooth operation of the diagnostic software. Identifying problems early can minimize downtime and enhance overall efficiency.

Identifying Software Problems

Users may encounter various issues while operating the diagnostic tool. Recognizing these software problems promptly can help in implementing the necessary solutions effectively.

Common Error Messages

- Error Code 1001: This indicates a connectivity issue with the diagnostic hardware. Ensure all cables are securely connected and the device is powered on.

- Error Code 2002: Often signifies a problem with the software installation. Reinstalling the software might resolve this error.

- Error Code 3003: Usually related to insufficient system resources. Close any unnecessary applications to free up memory.

- Error Code 4004: This error indicates an unsupported engine model. Verify compatibility with the connected equipment.

Quick Fixes

- For connectivity issues, check all physical connections and restart the hardware.

- If a reinstall is required due to an installation error, follow the proper uninstallation steps before reinstalling the diagnostic software.

- To resolve resource issues, performing a system reboot can often help streamline processes.

- For unsupported models, cross-check the device’s compatibility against the software’s specifications.

AGCO

AGCO ALLISON

ALLISON BENDIX

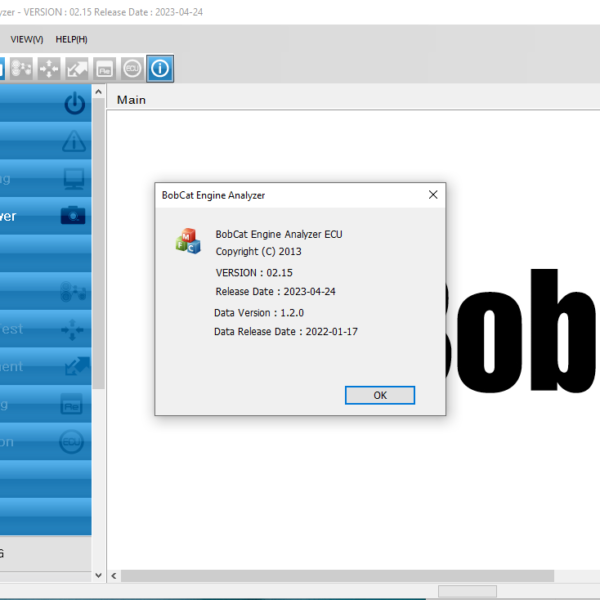

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

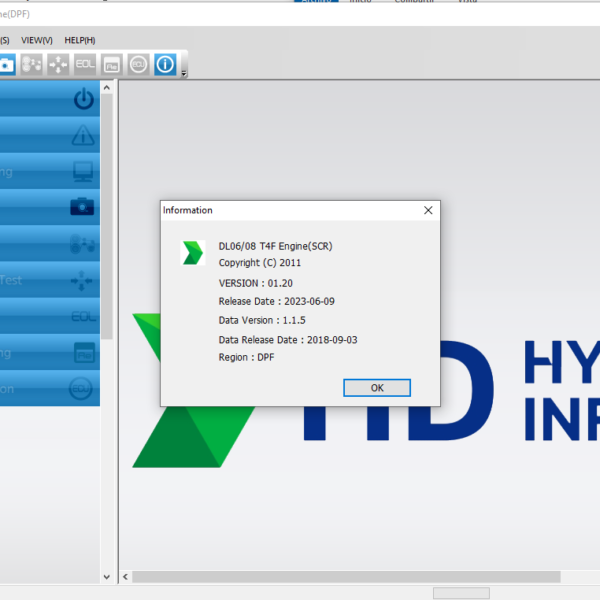

FREIGHTLINER HINO

HINO HITACHI

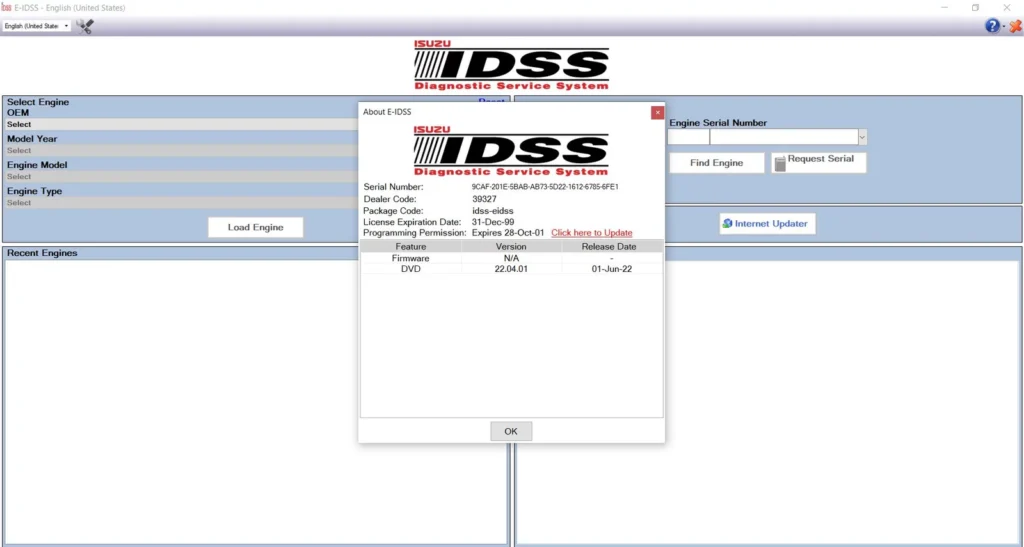

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

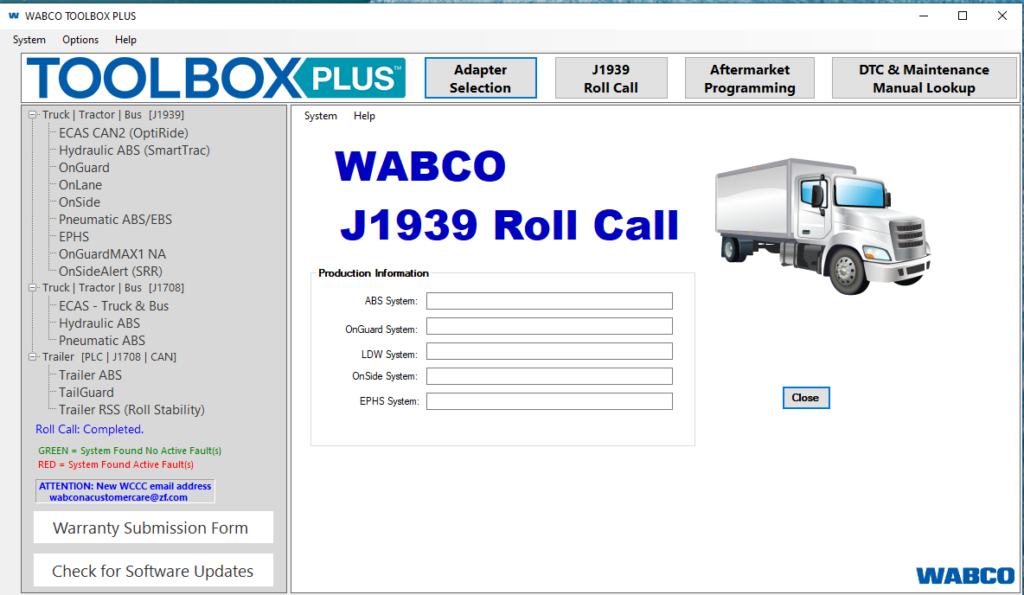

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.