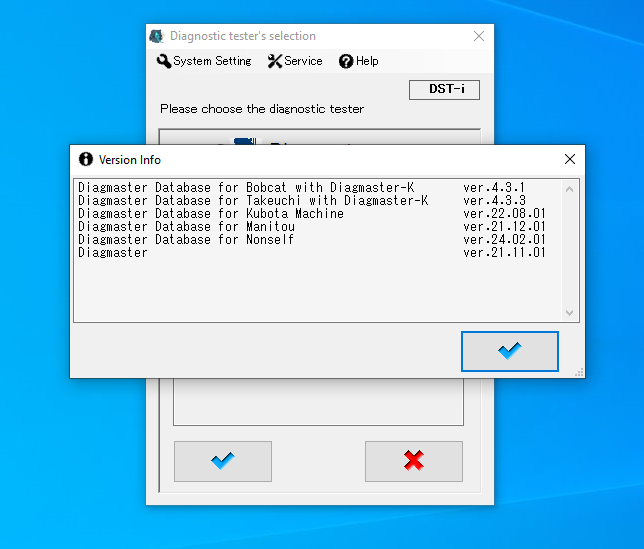

DIAGMASTER 21 11, BOBCAT 4 3 1, TAKEUCHI 4 3 3: Advanced Diagnostics for Heavy Machinery

DIAGMASTER 21.11 offers advanced diagnostic capabilities for heavy machinery, including support for brands like Bobcat, Takeuchi, Manitou, Kubota, and Nonself. This software facilitates precise diagnostics, enhancing equipment performance and maintenance. The following sections will explore the key features, compatibility, and specific advancements of DIAGMASTER 21.11 along with its application in various machinery models. Each brand benefits from unique updates and tools for optimized diagnostics and repairs.

Overview of DIAGMASTER 21.11

DIAGMASTER 21.11 stands out as a powerful tool for advanced diagnostics in heavy machinery. Its sophisticated features enable technicians to conduct thorough analyses of various equipment brands effectively.

Key Features

- Indefinite License: Users benefit from a permanent license without time constraints.

- Multi-language Interface: Supports numerous languages, including English, Spanish, French, and German.

- Extensive Database Access: Comprehensive coverage of diverse equipment and vehicle diagnostics.

Compatibility and System Requirements

DIAGMASTER 21.11 is designed to be compatible with popular operating systems. Specifically, it works with:

- Windows 7 (64-bit)

- Windows 10 (64-bit)

- Windows 11 (64-bit)

The software’s installation size is efficiently managed at 766 MB, with a total download of 937 MB, ensuring quick accessibility and minimal system impact.

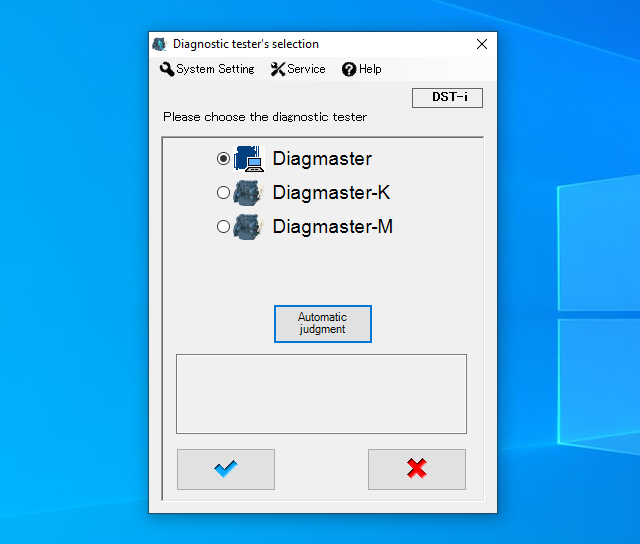

The Software Interface

The user interface of DIAGMASTER 21.11 combines simplicity with advanced functionality. Its design promotes ease of use while maximizing efficiency. Key aspects of the interface include:

- Intuitive Navigation: Streamlined access to diagnostic tools and error data.

- Multi-protocol Support: Allows communication with various ECUs through modern protocols like CAN.

- Cable and Connector Compatibility: Works with tools such as AGCO 2×4 CANUSB, ensuring diverse connectivity options.

These features collectively enhance the diagnostic process, enabling technicians to respond effectively to machinery issues.

Bobcat 4.3.1 Diagnostic Advancements

The Bobcat 4.3.1 version introduces significant upgrades that enhance diagnostic procedures for Bobcat machinery. These advancements streamline the process of identifying and addressing equipment issues, contributing to higher operational efficiency.

Updates and Improvements

With the release of Bobcat 4.3.1, users can expect a range of updates that fine-tune the diagnostic capabilities. Key improvements include:

- Enhanced error code identification, enabling faster resolutions of problems.

- Improved user interface for easier navigation and accessibility to diagnostic data.

- Integration of the latest communication protocols to support advanced machinery.

Impact on Machinery Performance

The impact of these diagnostic advancements extends directly to the performance of Bobcat equipment. Enhanced diagnostics lead to:

- Reduction in downtime, allowing for quicker turnaround in repairs.

- Improved preventive maintenance, identifying potential issues before they escalate.

- Increased overall reliability of machinery, resulting in better productivity on job sites.

Integration with Diagnostic Tools

Bobcat 4.3.1 also emphasizes seamless integration with various diagnostic tools available in the market. This includes:

- Compatibility with AGCO 2×4 CANUSB for improved connectivity.

- Support for the Bobcat Diagnostic Kit, enhancing the troubleshooting experience.

- Utilization of Nexiq USB Link for versatile diagnostic applications.

Takeuchi 4.3.3 Support Features

Takeuchi 4.3.3 offers specialized support features aimed at enhancing the diagnostic capabilities for compact machinery, ensuring optimal performance throughout their operational lifespan.

Specialized Diagnostics for Compact Machinery

This version of Takeuchi diagnostics is designed specifically for compact equipment, allowing technicians to identify issues more accurately and efficiently. It focuses on the unique systems employed in Takeuchi compact machinery, including:

- Transmission systems

- Hydraulic controls

- Engine performance metrics

By targeting these areas, the software can provide detailed insights, making maintenance and repairs more manageable for service professionals. The sophisticated analytical tools included facilitate a thorough interpretation of diagnostic codes and symbols.

Compatibility with Takeuchi Equipment

Takeuchi 4.3.3 is compatible with a wide range of equipment models, ensuring that various machinery types can utilize its advanced diagnostic features. Key aspects of compatibility include:

- Support for multiple models and configurations

- Integration with typical Takeuchi communication protocols

- Simplified connection methods for ease of use

This extensive compatibility enables technicians to service various equipment types effectively, thereby reducing downtime and enhancing productivity across the board. Each diagnostic function is specifically mapped to the functionalities of different machines.

Enhancement of Technical Handling

The improvements in Takeuchi 4.3.3 also focus on enhancing the technical handling of machines. Features such as real-time data monitoring and customizable diagnostic reports allow for greater flexibility in addressing issues. Key enhancements include:

- Improved user interface for easier navigation

- Advanced reporting tools to streamline the diagnostic process

- Accessible troubleshooting tips tailored to Takeuchi equipment

These upgrades ensure that technicians can address problems quickly and effectively, improving service quality while minimizing disruptions to operations.

Manitou 21.12 and Equipment Health

Manitou 21.12 introduces significant advancements aimed at enhancing equipment health, particularly in construction and agricultural contexts. This version includes a variety of tools and methodologies designed to ensure optimal performance and longevity of machinery.

Tools for Preventative Maintenance

Preventative maintenance is crucial for minimizing downtime and extending the life of heavy machinery. Manitou 21.12 provides tools that empower technicians to perform routine inspections and address potential issues before they escalate. Among these tools are:

- Regular health check alerts that notify users of maintenance needs.

- Diagnostic tools for real-time monitoring of machine performance.

- Detailed reporting features that track maintenance history and equipment status.

Diagnostic Accuracy for Versatile Machinery

With a focus on diagnostic precision, Manitou 21.12 allows for accurate assessments across a range of versatile machinery. Its advanced diagnostic algorithms analyze machine data to identify potential faults effectively. Key aspects include:

- Enhanced fault detection systems that provide clear error codes.

- Multi-language support for diverse operational teams.

- Integration with various Manitou models to ensure compatibility and reliability.

Benefits to Construction and Agriculture Sectors

The implementation of Manitou 21.12 positively impacts both the construction and agriculture sectors. By improving equipment health, it significantly contributes to higher productivity levels. Benefits include:

- Increased uptime due to timely diagnostics and repairs.

- Reduced operational costs through efficient maintenance practices.

- Enhanced safety measures by identifying potential issues early.

The Robust Kubota 22.08 Database

The Kubota 22.08 database is a significant component of the DIAGMASTER 21.11 software, specifically designed to enhance diagnostics for Kubota machinery and tractors.

Advancements in Tractor and Agricultural Machinery Diagnostics

This latest version introduces sophisticated diagnostic tools that cater specifically to the needs of tractor and agricultural equipment users. The advancements include:

- Enhanced error codes and troubleshooting procedures.

- Comprehensive access to service data and specifications.

- Real-time monitoring capabilities that catch issues before they escalate.

Impact of Accurate Information Access

Accessing accurate information is crucial for efficient machinery operation. With the Kubota 22.08 database, users benefit from:

- Up-to-date models and specifications tailored to various Kubota equipment.

- Streamlined diagnostics that lead to quicker turnaround times for repairs.

- Improved decision-making based on reliable data analytics.

Efficiency in Diagnostic Application

The efficiency of the Kubota 22.08 database translates into practical benefits for users. Some key aspects include:

- User-friendly interfaces that make navigation intuitive for technicians.

- Integration with existing diagnostic tools for greater flexibility.

- Minimized downtime as diagnostics become quicker and more precise.

Nonself 24.02 Level 9 Innovations

Nonself 24.02 Level 9 introduces significant advancements in diagnostic technology tailored for heavy machinery, enhancing real-time performance assessment and troubleshooting capabilities.

Expansion of Diagnostic Capabilities

The introduction of Nonself 24.02 Level 9 has broadened the scope of diagnostic functionalities. This version enhances the ability to identify and correct issues promptly, reducing the operational downtime of machinery.

- Improved error detection algorithms

- Enhanced data analysis tools for performance tracking

- Broader compatibility with various machinery brands and models

These capabilities allow technicians to perform more thorough evaluations and gain deeper insights into the health of equipment, which leads to more timely interventions.

Integration of Modern Communication Protocols

This iteration emphasizes seamless connectivity with modern communication protocols. By implementing advanced networking options, Nonself 24.02 Level 9 enables better interaction between diagnostic tools and machinery systems.

- Support for CAN bus and other communication standards

- Ability to integrate with existing diagnostic equipment

- Real-time data sharing to enhance diagnostics accuracy

This integration facilitates smoother operations and allows for quicker diagnostics, ultimately supporting the efficiency of machinery in both construction and agricultural settings.

The Future of Diagnostic Technology

The advancements in Nonself 24.02 Level 9 set a precedent for future developments in diagnostic technologies. As manufacturers continue to innovate, the emphasis will be placed on creating devices that not only diagnose but also predict potential failures.

- Incorporation of AI-driven diagnostic tools

- Predictive maintenance features to foresee potential issues

- Greater focus on user-friendly interfaces for technicians

These innovations are expected to significantly impact the effectiveness and reliability of machinery, ensuring they remain in optimal working condition.

Modern Interfaces and Connectivity Tools

Modern interfaces play a crucial role in enhancing the diagnostic capabilities of heavy machinery. These tools ensure seamless communication between diagnostic software and equipment, which optimizes the process of identifying and resolving issues.

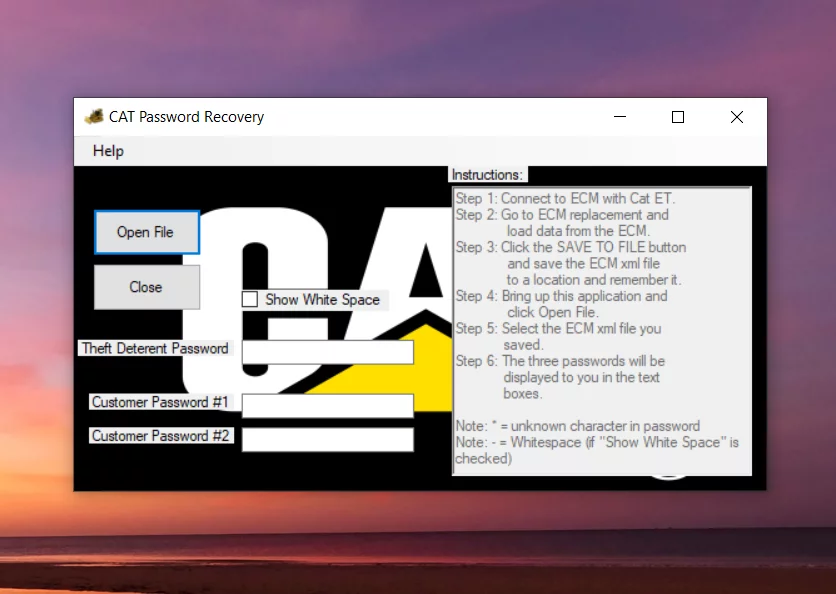

AGCO 2×4 CANUSB

The AGCO 2×4 CANUSB is an essential tool that facilitates the connection of diagnostic software to various agricultural machinery. This device utilizes Controller Area Network (CAN) technology, allowing users to access real-time data from the equipment’s electronic control units. Its compact design ensures easy handling and compatibility with multiple systems.

Bobcat Diagnostic Kit Features

The Bobcat Diagnostic Kit provides specialized features tailored for Bobcat machinery. Key components of the kit include:

- Wireless connectivity for convenient data access.

- User-friendly interface, allowing for quick navigation and interpretation of diagnostics.

- Regular updates that keep the diagnostic tool in sync with the latest machinery modifications.

This kit enhances technical efficiency and aids technicians in pinpointing machine issues with precision.

Nexiq USB Link Compatibility

Nexiq USB Link provides another vital avenue for connecting diagnostic software to various machines. This device is known for its broad compatibility with numerous brands and models. Key benefits include:

- Ability to communicate with multiple ECUs, enabling comprehensive diagnostics.

- Robust construction designed for heavy-duty environments.

- Compatibility with advanced vehicle communication protocols, ensuring effective diagnostics.

Such tools are indispensable for technicians who require reliable and efficient connections for accurate diagnostic outcomes.

Continuous Training and Updates

In the rapidly evolving field of heavy machinery diagnostics, continuous training and updates are crucial for maintaining efficiency and accuracy in the repair process.

Importance of Ongoing Education

Staying updated with the latest technological advancements is essential for technicians working with complex diagnostic tools. Continuous education provides numerous benefits:

- Enhances troubleshooting skills, allowing for quicker resolutions to issues.

- Ensures familiarity with new software updates and their functionalities.

- Promotes an understanding of evolving machinery technologies and protocols.

Keeping Up with Technological Advancements

Modern diagnostic software, like DIAGMASTER 21.11, undergoes frequent updates that introduce new tools and features. Technicians must keep pace with these changes through various means:

- Participating in specialized training sessions and workshops.

- Accessing online resources, including webinars and tutorials.

- Engaging in peer discussions to share insights and experiences.

The Role of Version Updates in Diagnostics

Version updates play a vital role in enhancing diagnostic capabilities. Regular updates lead to:

- Increased accuracy in fault detection and repair processes.

- Integration of new vehicles and equipment into existing diagnostic systems.

- Improved compatibility with advanced communication protocols.

Therefore, ongoing training on these updates ensures that technicians remain proficient in their work, maintaining high standards of service and support.

The Impact of Diagnostic Software in the Industry

The integration of diagnostic software has revolutionized the heavy machinery sector, providing significant advantages that directly affect operations and service quality.

Reducing Equipment Downtime

One of the primary benefits of advanced diagnostic software is its ability to minimize equipment downtime. Quick and effective identification of issues allows for swift repairs, thus:

- Preventing minor problems from escalating into major failures.

- Ensuring machinery is operational and available when needed.

- Facilitating scheduled maintenance that adheres to operational demands.

These elements together contribute to maintaining continuity in productivity, which is crucial in industries where machinery plays a central role.

Enhancing Operational Efficiency

Operational efficiency thrives when diagnostic software provides accurate and timely data. The software helps technicians analyze machine performance with precision, leading to:

- Optimized workflows through effective issue resolution.

- Enhanced machine performance due to informed maintenance decisions.

- Increased lifespan of equipment by ensuring proper care and timely upgrades.

This optimization not only elevates the performance levels of individual machines but also enhances the overall productivity of fleets.

Increasing Customer Satisfaction

In industries dependent on heavy machinery, customer satisfaction is heavily influenced by the operational capabilities of those machines. The use of diagnostic software can:

- Provide accurate estimates for repair times, allowing customers to plan accordingly.

- Improve reliability, thus reducing unexpected breakdowns that could disrupt operations.

- Enhance service quality by offering precise solutions faster.

As a result, companies utilizing advanced diagnostic tools are likely to see improved client relationships and a stronger market presence.

FAQs about DIAGMASTER 21.11 and Supported Brands

This section addresses common questions and concerns regarding DIAGMASTER 21.11 and its compatibility with various machinery brands. Understanding these FAQs can help users navigate potential challenges and leverage the software more effectively.

Common User Concerns

Users often have several concerns related to the functionality and usability of DIAGMASTER 21.11. Some of the most frequently asked questions include:

- What types of machinery and vehicles does DIAGMASTER 21.11 support?

- Can the software be used on different operating systems, and are there specific hardware requirements?

- What kind of training is recommended for new users to effectively utilize the software?

Addressing these concerns is crucial for ensuring that technicians can maximize the utility of the software across various equipment.

Troubleshooting and Support

In the event of issues with DIAGMASTER 21.11, users may seek assistance through troubleshooting steps and support options. Common troubleshooting queries include:

- How can error codes be interpreted accurately using the software?

- What are the steps to resolve compatibility issues with specific models?

- Is there a user manual or guide to assist with technical problems?

Access to reliable support resources is essential for users to maintain the operational efficiency of their diagnostic processes.

Future Developments and Updates

As technology evolves, so does the need for continued updates and new features in diagnostic software. Users are often curious about:

- What new features are planned for upcoming releases of DIAGMASTER?

- Will there be regular updates to ensure compatibility with newer machinery models?

- How does user feedback influence future software developments?

Keeping abreast of future developments helps users understand how to adapt to changing technology and continuously improve their diagnostic capabilities.

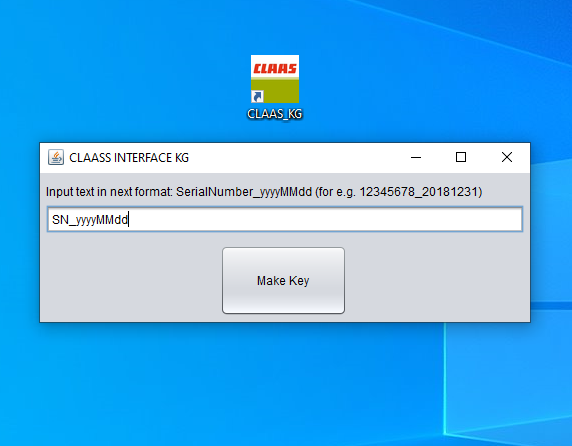

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The DOOSAN DIAGNOSTIC TOOL T3 EDC17 1.1.5 [2022.09] is a powerful software designed for diagnosing issues in heavy machinery. It is specifically built for Doosan equipment, providing efficient solutions for maintenance and repairs. This tool features advanced diagnostic capabilities, a user-friendly interface, and real-time data visualization. It supports various Doosan models, enhancing reliability and reducing downtime in operations.](https://ecmtrucks.com/wp-content/uploads/2024/08/88-2.png)

Reviews

Clear filtersThere are no reviews yet.