CNH EST 9 8 ENGINEERING: Revolutionizing Equipment Diagnostics and Maintenance

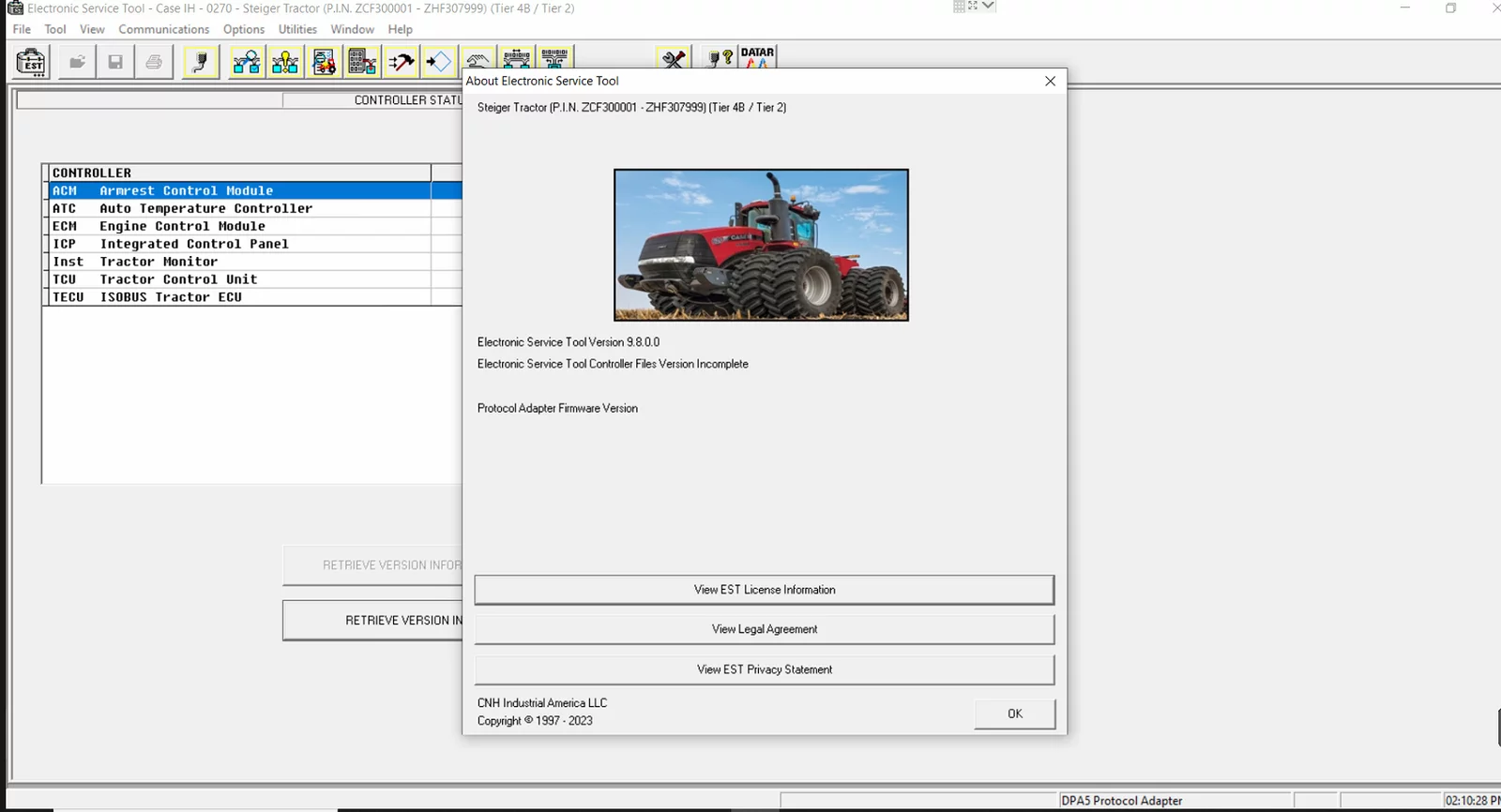

CNH EST 9 8 Engineering is an advanced diagnostic software tool designed for CNH Industrial equipment. It enables technicians to perform thorough analyses and enhances operational efficiency across various machines. This software provides essential functionalities like accessing control modules, reading trouble codes, and performing system tests. Its user-friendly interface and compatibility with multiple brands make it a vital resource for maintenance and troubleshooting.

What is CNH EST 9 8 Engineering?

CNH EST 9 8 Engineering serves as a sophisticated tool for diagnosing and maintaining CNH Industrial equipment. This tool is paramount for technicians working in agricultural, construction, and commercial vehicle sectors.

Key Features of the Software

- Advanced diagnostic capabilities for electronic systems

- Access to control modules for real-time data analysis

- Ability to read and clear trouble codes, enhancing fault management

- Parameter adjustments for tailored equipment operation

- Collaboration features allowing real-time support among technicians

How the Diagnostic Tool Works

The functionality of CNH EST 9 8 revolves around its capacity to connect with various equipment modules. Technicians can conduct system tests that examine performance metrics, while reading error codes offers insights into operational issues. This integration facilitates quick diagnostics and effective troubleshooting.

Advantages Over Previous Versions

Version 9 8 introduces several enhancements compared to earlier iterations. Key improvements include:

- Expanded database of fault codes for accurate diagnostics

- Improved user interface for streamlined navigation

- New features for data management and analysis

Such upgrades significantly increase efficiency, providing technicians with better tools for effective maintenance.

Core Functionalities

The core functionalities of the software provide a comprehensive toolset designed for effective diagnostics and maintenance. Users can access various features that enhance their ability to maintain and troubleshoot equipment efficiently.

Accessing Control Modules

One of the key features is the ability to access control modules within the machinery. This functionality enables technicians to verify configuration settings and monitor the operational status of different components, facilitating swift fault identification.

Reading and Clearing Trouble Codes

The tool empowers users to read and clear trouble codes (DTCs) stored in the system. This capability is essential for diagnosing issues and restoring the equipment to normal operation once repairs have been made.

Performing System Tests

System testing is crucial for ensuring all components function as intended. The software allows for comprehensive performance checks and diagnostic tests, ensuring that equipment operates within manufacturer specifications.

Parameter Adjustments

Customization is vital for optimal performance. It enables technicians to make parameter adjustments tailored to specific tasks, resulting in increased efficiency and productivity.

Real-Time Collaboration Features

In modern work environments, teamwork is essential. The software includes tools for real-time collaboration among engineers and technicians, allowing them to share insights and resolve complex issues more effectively.

Compatibility and Support

Ensuring compatibility and support is crucial when utilizing diagnostic software. CNH EST 9 8 Engineering is designed to work seamlessly with a variety of equipment brands and models.

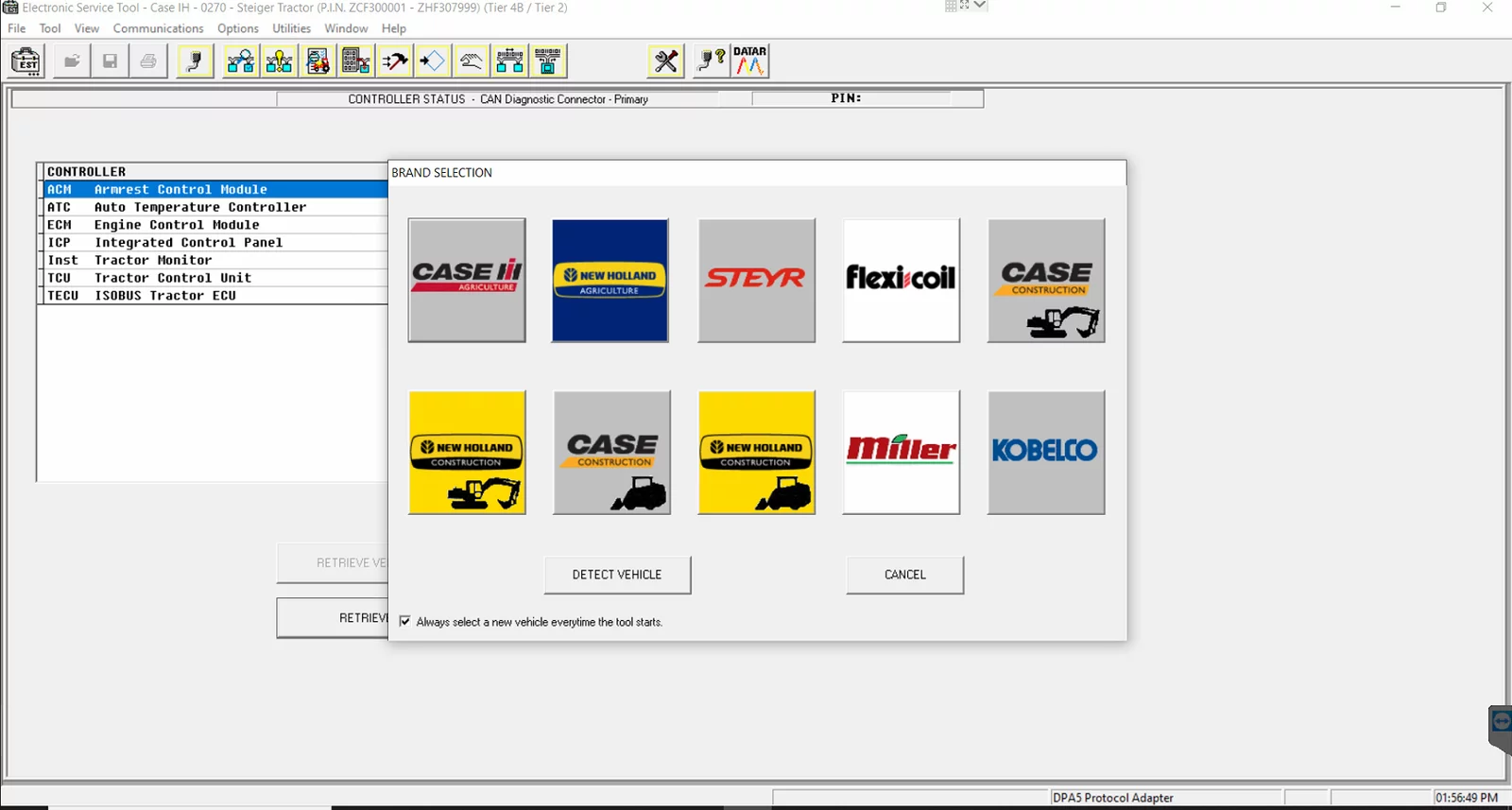

Supported Brands and Models

The software provides extensive support across multiple brands. This compatibility enhances its versatility for technicians working with diverse machinery.

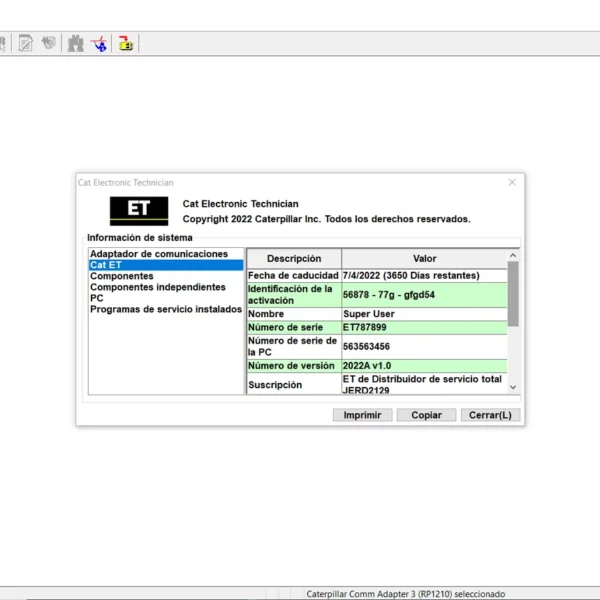

New Holland and Case

New Holland and Case IH are among the primary brands supported by the software. These brands encompass a wide range of agricultural and construction equipment, enabling precise diagnostics and maintenance capabilities.

Kobelco and Steyr

In addition to New Holland and Case, the software also covers Kobelco and Steyr. This broadens the scope of equipment that technicians can manage effectively.

Supported ECUs and Controller Files

CNH EST 9 8 Engineering is compatible with various Electronic Control Units (ECUs) and controller files. This ensures that the software can interface with essential vehicle systems for accurate diagnostics.

Collaborating Brands: Beyond New Holland

Beyond New Holland, the software’s compatibility extends to other notable brands. These include:

- Flexi-Coil

- Orenstein & Koppel (O&K)

This collaboration with various brands underscores the software’s capability to support numerous models, allowing technicians to address a wide array of equipment under a unified platform.

User Experience and Interface

The usability of software is crucial for effective operation. A well-designed interface enhances the user experience and facilitates efficient diagnostics and maintenance tasks.

Design Principles

The design of CNH EST 9 8 Engineering emphasizes clarity and simplicity. Key principles include:

- Intuitive layouts that minimize complexity.

- Consistent use of colors and icons for better recognition.

- Prioritization of critical functions to streamline workflows.

User-Friendly Navigation

Navigation within the software is streamlined to promote efficiency. Users can expect:

- Logical menu structures that facilitate quick access to tools.

- Search functionality that allows for swift information retrieval.

- Contextual help options to assist users at every step.

Interface Enhancements in Version 9 8

The latest iteration of the software includes several significant enhancements to improve user engagement:

- Redesigned dashboard featuring customizable widgets for prioritized data.

- Improved graphical interfaces for easier interpretation of results.

- Enhanced responsiveness, providing seamless experience across devices.

Technical Requirements

To ensure optimal performance and functionality, specific technical requirements must be met for using the software effectively. This includes the necessary operating system, hardware specifications, and considerations for internet connectivity.

Required Operating System Specifications

The software is designed to operate on the following systems:

- Windows 10 (32 or 64 bits)

- Windows 11 (32 or 64 bits)

Necessary Hardware for Optimal Performance

The hardware requirements are crucial for delivering a smooth user experience:

- Modern processor

- At least 4 GB of RAM

- Minimum 100 GB of free storage on the hard drive

Internet Connectivity and Its Importance

A stable internet connection is essential for various functions within the software:

- For updates and activation of the software

- To access the online database with the latest diagnostic information

- For features that require real-time collaboration with other technicians

Installation and Updates

The installation and updating of the software are essential for maintaining its performance and ensuring access to the latest features.

How to Install the Software

Installing CNH EST 9.8 requires a few straightforward steps:

- Download the installation file from the official CNH Industrial website.

- Ensure that the device meets the necessary system requirements.

- Run the installation file and follow the on-screen prompts.

- Activate the software using the provided license key.

- Reconnect to the internet to enable the registration of the software.

This process helps ensure that the software is correctly installed and ready for use.

Best Practices for Updating CNH EST

Regular updates are crucial for optimal functionality. To ensure an efficient updating process:

- Check for updates at least once a month.

- Back up existing data before initiating the update.

- Follow instructions provided in the update notifications.

- Restart the software after the update to apply changes.

- Monitor the performance post-update to identify any issues.

Staying up-to-date not only enhances performance but also improves security against potential vulnerabilities.

Troubleshooting with CNH EST

Troubleshooting with CNH EST involves systematic approaches to identify and resolve issues within CNH equipment. Utilizing the diagnostic tools effectively can enhance maintenance operations and ensure machines run smoothly.

Common Diagnostic Procedures

Implementing standard diagnostic procedures is essential in troubleshooting. Typical steps include:

- Accessing the diagnostic tool to review error codes.

- Running system checks to identify areas of malfunction.

- Performing necessary parameter adjustments based on findings.

Advanced Troubleshooting Techniques

For more complex issues, advanced troubleshooting techniques may be necessary. These strategies can involve:

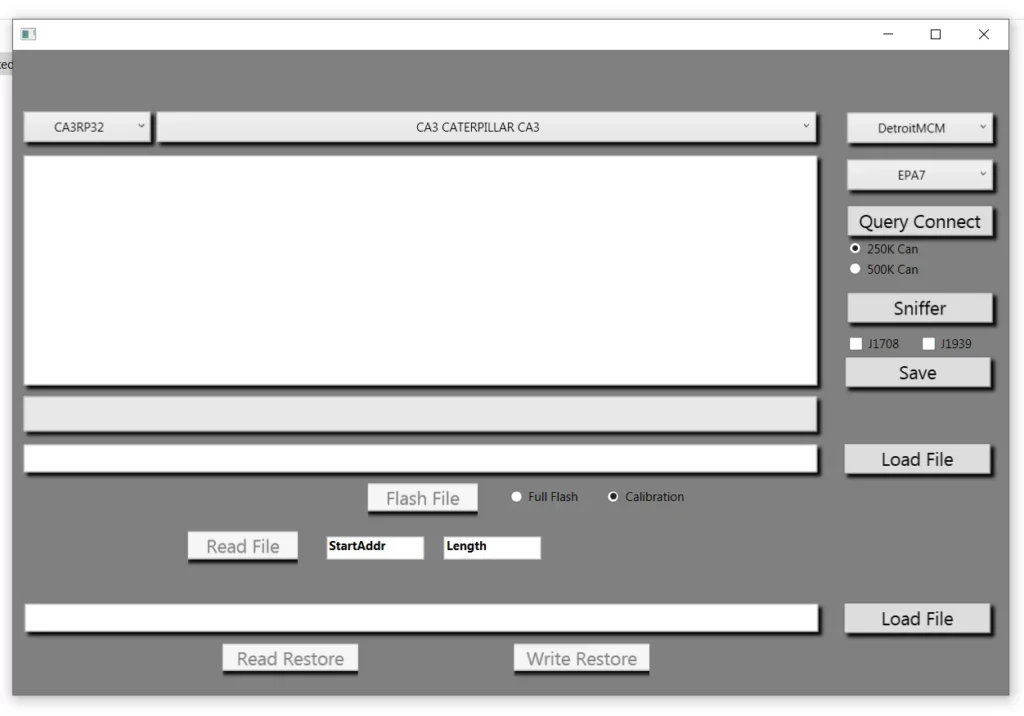

- Interpreting live data streams for real-time diagnostics.

- Utilizing simulation tools within the software to replicate faults.

- Collaborating with team members for enhanced problem-solving capabilities.

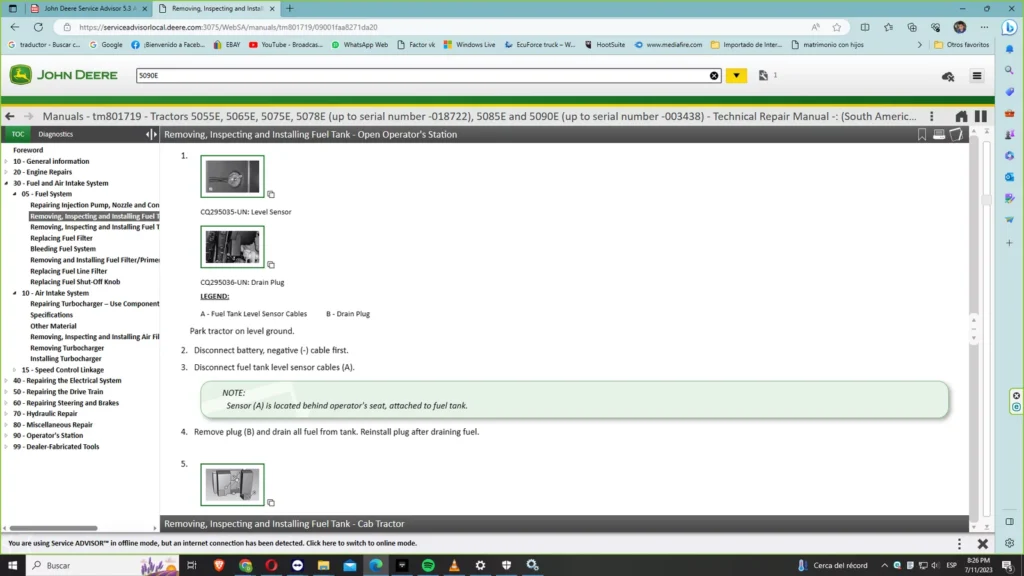

Step-by-Step Schematics and Procedures

Adhering to structured workflows is critical for effective troubleshooting. Step-by-step schematics outline the following actions:

- Identify the issue based on diagnostic readings.

- Refer to system schematics for location-specific checks.

- Document findings and actions taken for future reference.

Frequently Asked Questions

This section addresses common inquiries regarding the diagnostic software, its functionalities, and usability concerns. Understanding these aspects can help technicians and users maximize their experience with the tool.

Software Capabilities and Limitations

CNH EST 9.8 Engineering offers a robust set of features, including:

- Access to control modules

- Reading and clearing trouble codes

- Custom parameter adjustments

- Conducting detailed system tests

However, there are limitations. Some older models may not be entirely compatible, and specific advanced diagnostics may require additional tools or software updates.

Best Use Cases for Technicians

This software is ideal for:

- Troubleshooting complex machinery issues

- Performing routine maintenance checks

- Customizing machine parameters for optimal performance

- Collaborating with team members in real-time

These scenarios enhance not only the efficiency of repairs but also the longevity of equipment.

Addressing Common Misunderstandings

Some misconceptions about CNH EST 9.8 include:

- It can diagnose all machinery problems without additional input.

- Older versions of the software are equally effective as the latest.

- It requires extensive technical knowledge to operate.

Clarifying these misunderstandings can improve user confidence and support successful diagnostics.

Contact Us

If assistance is needed regarding CNH EST 9 8 Engineering, support and resources are readily available for users.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

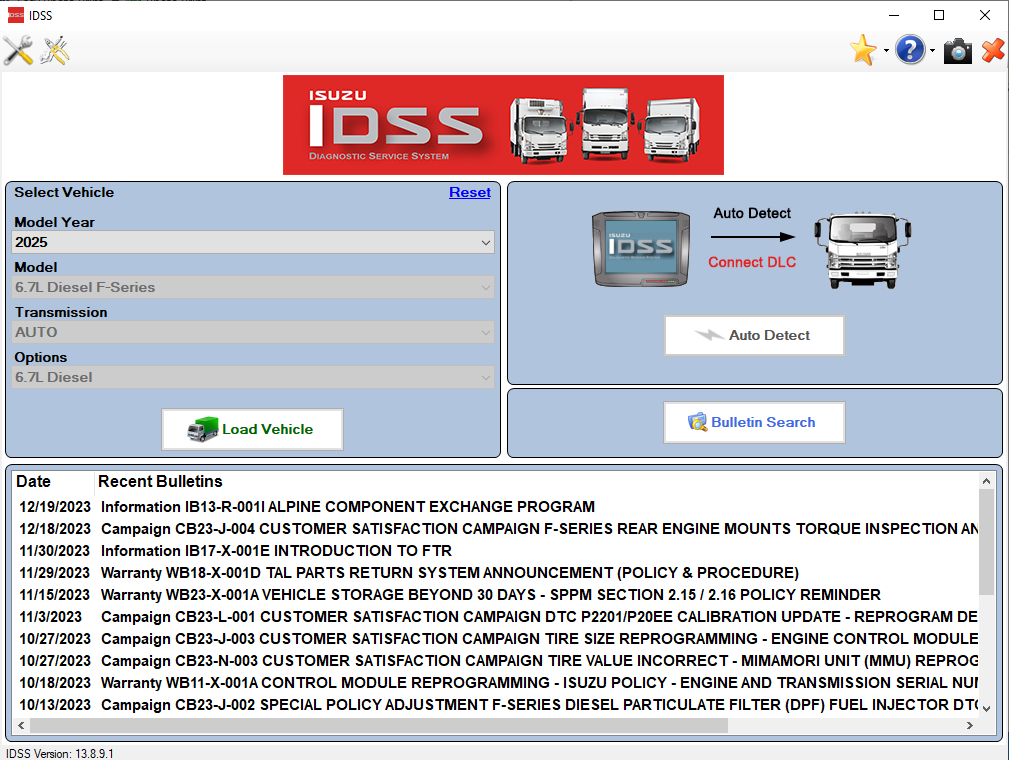

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

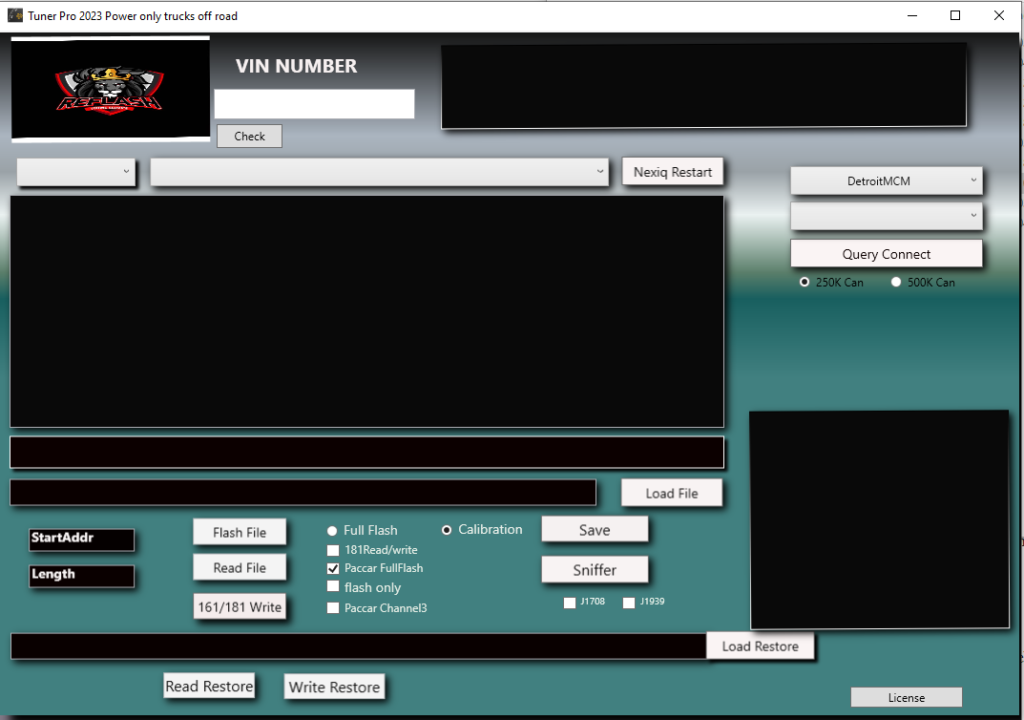

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

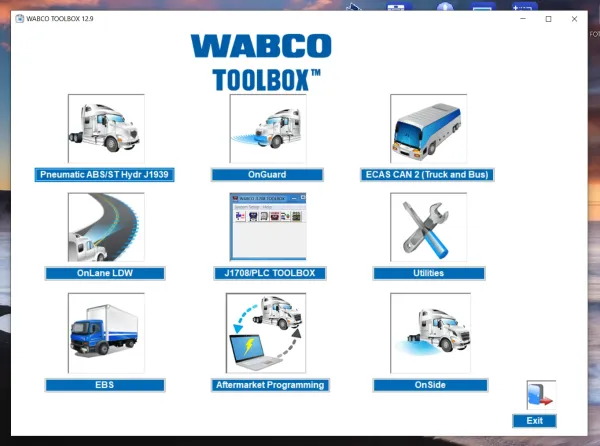

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The Doosan E-Doctor Industry Standard 2.4.0.7 [2023.06], released in June 2023, is a vital tool for diagnosing and maintaining heavy machinery. This software enhances efficiency and minimizes downtime by providing detailed engine diagnostics. Key features include multi-language support, an intuitive user interface, and the ability to conduct remote diagnostics. Compatibility with Windows 10 and 11 ensures seamless installation, while TeamViewer support facilitates remote assistance and installation for users.](https://ecmtrucks.com/wp-content/uploads/2024/08/55-1.png)

Reviews

Clear filtersThere are no reviews yet.