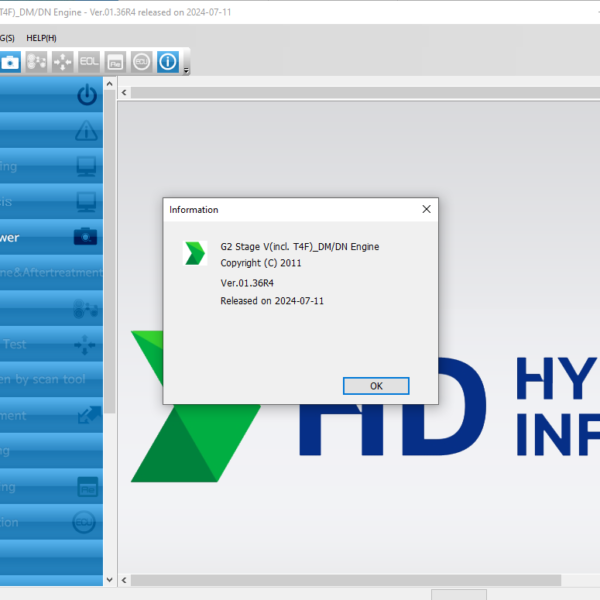

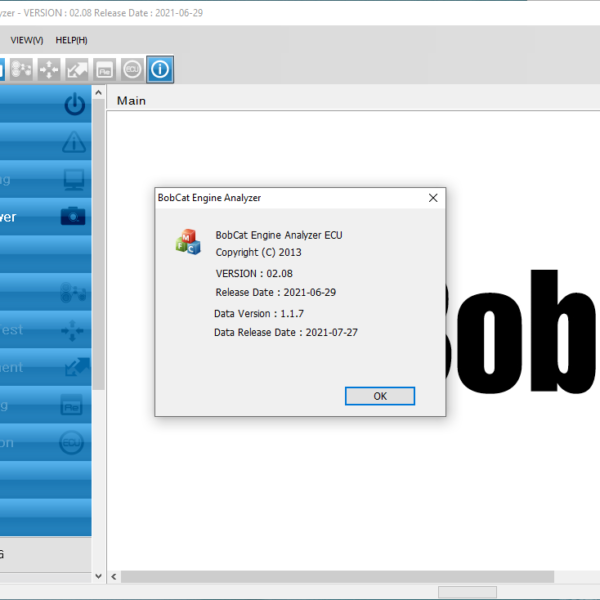

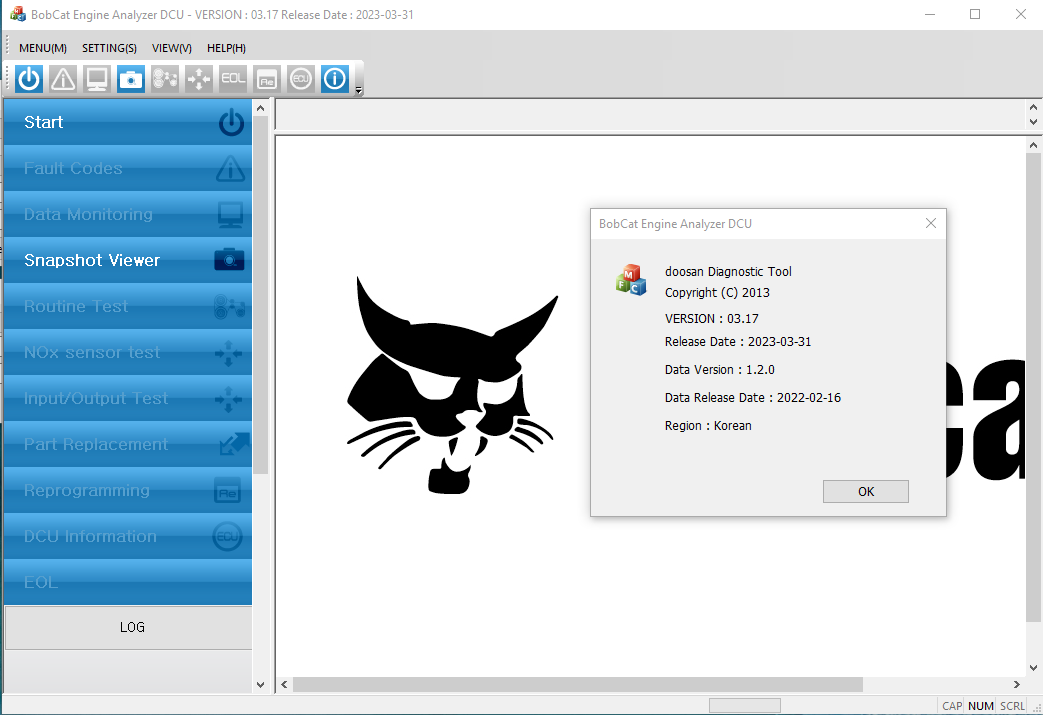

BOBCAT ENGINE ANALYZER DCU 03 17 2023 03: Essential Diagnostic Tool for Heavy Machinery

The BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 is a specialized diagnostic software aimed at enhancing the performance of Bobcat machinery. This tool simplifies the diagnostic process, making it essential for maintenance and troubleshooting in heavy equipment. It offers key features such as compatibility with multiple Windows versions and diagnostic capabilities for various Bobcat engines. Additionally, support for remote installation using TeamViewer ensures convenient setup for users.

Product Overview

This section provides an in-depth look at the features and specifications of the diagnostic software for Bobcat equipment.

Software Description

The BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 is specifically engineered to enhance the maintenance and diagnostic processes of Bobcat machinery. It serves as an indispensable tool for technicians, allowing them to efficiently manage engine diagnostics, troubleshooting, and performance optimization. This software is tailored to meet the demands of modern construction and heavy equipment management.

Key Features

Several distinctive features set this diagnostic software apart, making it a valuable asset for heavy machinery professionals. The following key elements contribute to its functionality:

-

System Compatibility (Windows)

The software supports multiple versions of the Windows operating system, ensuring that users can install it on a range of devices. Compatible versions include:

- Windows 10 (64 bits)

- Windows 7 (32 and 64 bits)

- Windows 11 (64 bits)

-

File Size and Installation Requirements

The installation file has a size of 149 MB, while the total storage requirement expands to 614 MB once the software is installed. This necessitates ample disk space on the target device. It is imperative to verify system capacity before initiating the installation process.

-

License and Languages

The BOBCAT ENGINE ANALYZER offers a license that provides unlimited usage, allowing technicians to utilize the software without time constraints. The interface is available in both English and Korean, accommodating a diverse range of users globally.

Diagnostic Capabilities

The software’s primary function lies in its robust diagnostic capabilities, tailored to detect engine issues and streamline maintenance. Key diagnostic functions include:

-

Engine Diagnostics

Through detailed error code analysis, users can identify potential problems before they escalate into significant failures. This proactive approach greatly reduces downtime and repair costs.

-

Performance Monitoring

Continuous monitoring of engine performance is facilitated by the software, enabling users to make necessary adjustments and calibrations efficiently.

-

Calibration Procedures

The calibration functions allow for fine-tuning of the machinery, ensuring that equipment operates at its peak efficiency. These procedures are crucial for maintaining optimal performance in challenging work conditions.

Installation Process

Installing the BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 involves several key steps that ensure a smooth setup and optimal functionality. The process includes system verification, downloading the appropriate software, and completing the installation efficiently.

System Verification

Before beginning the installation of the BOBCAT ENGINE ANALYZER, it is crucial to verify that the computer system meets all necessary requirements. This ensures compatibility and prevents potential issues during the installation process.

- Check that the operating system is either Windows 7, Windows 10, or Windows 11, with the correct bit version.

- Ensure there is sufficient available storage space: at least 614 MB after installation.

- Confirm that any antivirus software will not interfere with the installation process.

Software Download

Once the system has been verified, the next step is to download the software. Acquiring it from a reputable source is essential to guarantee its authenticity and safety.

- Visit the official website or an authorized dealer to initiate the download.

- Select the correct version of the software to ensure compatibility with your operating system.

- Click the download link and wait for the file to fully download before proceeding.

Installation Steps

With the software downloaded, users can begin the installation process by following a clear sequence of steps that guide them through the setup.

Installation File Execution

After downloading the installation file, the next step is to execute it:

- Locate the downloaded file, typically found in the “Downloads” folder.

- Right-click on the installation file and select “Run as administrator” to ensure all necessary permissions are granted.

- Follow the on-screen instructions carefully, and proceed through the installation wizard.

Keygen Activation

After completing the installation, activating the software is necessary to unlock its full capabilities:

- Locate the keygen tool that accompanies the software download.

- Run the keygen application and follow its instructions to generate a valid activation key.

- Input the generated key into the appropriate field within the software to complete the activation process.

Remote Installation Support (TeamViewer)

For users who may encounter challenges during the installation process, remote support is available to facilitate a seamless setup. Utilizing TeamViewer allows for assistance by tech experts in real time.

- Ensure that TeamViewer is downloaded and installed on your computer.

- Launch TeamViewer and share your ID and password with the support team.

- A qualified technician will remotely access your system to assist with the installation, providing expert guidance throughout the process.

Diagnostic Functions

The diagnostic functions of the BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 are designed to enhance the maintenance and efficiency of Bobcat machinery. These functions play a vital role in identifying issues, optimizing performance, and ensuring equipment longevity.

Maintenance and Prevention

Effective maintenance and prevention are essential for the longevity of machinery. The software provides tools that allow users to proactively address potential issues before they escalate into significant problems.

Error Code Interpretation

One of the primary features of this analyzer is its ability to interpret error codes generated by the equipment. This functionality is crucial as it enables technicians to understand the specific problems affecting the machinery. The software translates diagnostic trouble codes (DTCs) into understandable terms, making it easier to identify the underlying issues.

Understanding these codes allows for quicker decision-making, as technicians can implement solutions promptly. Accurate error code interpretation can significantly reduce downtime, thereby enhancing operational efficiency.

Maintenance Scheduling

Regular maintenance is critical for preventing mechanical failures. The analyzer aids in creating a maintenance schedule based on usage and performance metrics. By tracking the operational history, it can provide reminders for routine checks and necessary servicing, ensuring that machinery remains in optimal condition.

Implementing a structured maintenance schedule helps mitigate the risk of unexpected breakdowns. This proactive approach maintains productivity levels and extends the life of the equipment.

Fault Diagnosis

The fault diagnosis capabilities of the BOBCAT ENGINE ANALYZER are a cornerstone of its utility. By systematically analyzing the machinery’s performance data, the software can pinpoint faults within various systems. This level of diagnostics allows for comprehensive assessments rather than superficial fixes.

Technicians benefit from in-depth assessments, as the analyzer provides insights into potential causes of failures. These diagnostic reports can streamline repair processes, making them more efficient and effective.

Performance Optimization

The analyzer also focuses on performance optimization, which is essential for ensuring machinery operates at its best. By calibrating settings and fine-tuning performance parameters, users can achieve greater efficiency and enhanced productivity.

Calibration Functions

Calibration functions are integral to the diagnostic toolkit. They allow for the adjustment of various aspects of the machinery to ensure everything operates smoothly. This process includes aligning sensors, refreshing control unit parameters, and tuning engine performance.

Proper calibration can lead to improved fuel efficiency, reduced emissions, and a noticeable enhancement in the overall performance of the machinery. Regularly utilizing these calibration features is key to maintaining optimal operation standards.

Compatibility and Interfaces

The compatibility of the BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 is vital for ensuring its effectiveness across various machinery and diagnostic tools. This section delves into the different vehicles and equipment it is compatible with, as well as the diagnostic interfaces that enhance its functionality.

Compatible Vehicles and Equipment

This software supports a wide range of vehicles, ensuring that technicians can use it with various machines in the field. Here are the major categories:

Bobcat Equipment

As the primary focus of the BOBCAT ENGINE ANALYZER, the compatibility spans numerous Bobcat models. This includes but is not limited to:

- Bobcat compact excavators

- Bobcat skid-steer loaders

- Bobcat utility vehicles

- Bobcat telehandlers

Each of these machines can benefit from the software’s diagnostic capabilities, enabling timely maintenance and reduction of downtime. The software identifies issues specific to the Bobcat engine specifications and system configurations.

Ford Cargo Diagnostic Kit

The BOBCAT ENGINE ANALYZER also accommodates the Ford Cargo diagnostic kit, allowing seamless integration for users who work with Ford vehicles. This compatibility adds versatility to the tool, broadening its usage for technicians who handle a mix of machinery brands.

Diagnostic Interfaces

In addition to its compatibility with various vehicles, the BOBCAT ENGINE ANALYZER connects with multiple diagnostic interfaces. This feature allows enhanced diagnostic capabilities across a broader spectrum of equipment.

UVIM Diagnostic Kit

The UVIM Diagnostic Kit is another interface supported by the software. This kit enables users to monitor and diagnose other machinery, thus supporting a multifaceted approach to equipment management. Its integration with the BOBCAT ENGINE ANALYZER maximizes efficiency during maintenance procedures.

VCI Ford Cargo Diagnostic Kit

The VCI Ford Cargo Diagnostic Kit further enhances the compatibility spectrum. This interface specializes in vehicle diagnostics, making it a valuable asset for those who manage Ford trucks and want to incorporate Bobcat engines into their maintenance routines. The combination of tools ensures comprehensive coverage for technicians handling diverse equipment.

Software Updates

Keeping the software current is essential for optimal functionality and access to the latest features. Regular updates ensure the diagnostic tool remains effective and efficient for users working with Bobcat machinery.

Update Process

To update the BOBCAT ENGINE ANALYZER DCU, users must follow a straightforward procedure. This process typically involves periodically checking for updates via the software interface or the official website. By establishing a routine for updates, users can benefit from enhancements that improve diagnostic accuracy and overall performance. Here are the steps involved in the update process:

- Open the BOBCAT ENGINE ANALYZER DCU software.

- Navigate to the ‘Settings’ or ‘Help’ section.

- Look for the ‘Check for Updates’ option.

- Follow the prompts to download and install any available updates.

New Features in Updates

Each software update may introduce new functionalities that can significantly enhance the user experience and technical capabilities of the diagnostic tool. The enhancement of features ensures that the software evolves to meet the demands of modern machinery diagnostics.

Performance Enhancements

Recent updates have focused on boosting the software’s overall performance. This includes improvements in speed, response time, and data processing capabilities. Accelerated diagnostic processes mean that technicians can spend less time troubleshooting and more time on actual repairs and maintenance. Noteworthy performance improvements from past updates include:

- Faster error code retrieval for quicker diagnostics.

- Enhanced data visualization features for easier interpretation of diagnostics.

- Improved interface responsiveness for a smoother user experience.

Bug Fixes

Every software update typically addresses various bugs and issues reported by users. Fixing these bugs is crucial for maintaining the reliability of the software. Through consistent updates, the development team works diligently to resolve problems that could hinder functionality. Common bug fixes include:

- Resolution of connectivity issues with diagnostic interfaces.

- Corrections to erroneous error codes generated during diagnostics.

- Patches to improve interface compatibility with different operating systems.

Comparisons with Other Products

When evaluating diagnostic tools for heavy machinery, it is crucial to consider how they stack up against competitors. The following comparisons highlight key features and performance aspects of the BOBCAT ENGINE ANALYZER DCU 03 17 2023 03 in relation to other notable products in the market.

JCB Servicemaster 4

Feature Comparison

The JCB Servicemaster 4 is a well-known diagnostic tool that shares some functionality with the BOBCAT ENGINE ANALYZER. Key features include:

- Comprehensive diagnostic capabilities for JCB machinery.

- Access to real-time data and fault codes.

- Multilingual support, enhancing usability across diverse regions.

While both tools offer similar diagnostic features, the BOBCAT ENGINE ANALYZER is particularly tailored for Bobcat equipment, ensuring more precise diagnostics for its specific models.

Performance Comparison

Performance metrics reveal critical differences between these two tools. The BOBCAT ENGINE ANALYZER typically provides faster fault code interpretation compared to the JCB Servicemaster 4. This speed can significantly reduce downtime during maintenance tasks. Users often report greater accuracy in diagnosing flaws with Bobcat machinery when using the BOBCAT ENGINE ANALYZER, thanks to its targeted software design.

Dddl 8.20 Sp0

Feature Comparison

Dddl 8.20 Sp0 is another competitor in the diagnostic software market. It comes with several features that are relevant for various vehicle diagnostics:

- Designed to work with a wide range of diesel engines.

- Includes advanced troubleshooting guides.

- Provides detailed performance metrics and logging functionalities.

The focus of Dddl 8.20 Sp0 is broader, accommodating a variety of engine brands. Conversely, the specificity of the BOBCAT ENGINE ANALYZER to Bobcat machines allows for deeper insights into performance and issues related to Bobcat engines.

Performance Comparison

In terms of performance, the BOBCAT ENGINE ANALYZER is often praised for its quicker processing times and user-friendly interface. The tool has a dedicated design for Bobcat engines, allowing for enhanced calibration and maintenance tasks. Many users find that the BOBCAT ANALYZER’s capabilities lead to improved machinery uptime, which is essential in demanding work environments.

User FAQs

This section addresses common questions users have regarding the installation, usage, and support of the BOBCAT ENGINE ANALYZER DCU 03 17 2023 03. The following subsections provide detailed insights into potential installation issues, diagnostic tool usage, and available remote support services.

Common Installation Issues

Software Compatibility

One of the most frequent concerns during installation relates to software compatibility. The BOBCAT ENGINE ANALYZER is designed to operate seamlessly on various Windows platforms, including Windows 7 (32 and 64 bits), Windows 10 (64 bits), and Windows 11 (64 bits). Users should ensure their systems meet these specifications to prevent issues. If problems arise, checking for the latest Windows updates may resolve compatibility conflicts. Incompatibility can also occur due to outdated hardware; therefore, a system review before installation is advisable.

Activation Problems

Activation issues can hinder users from fully utilizing the software’s capabilities. During the activation phase, ensure that any antivirus software is temporarily disabled, as it may interfere with the process. If the activation code is not accepted, double-check for any typographical errors. Users experiencing persistent activation failures may need to seek assistance from technical support for resolving keygen or licensing issues, ensuring that all operational features are unlocked.

Using Diagnostic Tools

Error Code Troubleshooting

Interpreting error codes can be challenging without proper guidance. The BOBCAT ENGINE ANALYZER provides an intuitive interface that simplifies error code diagnostics. Users are encouraged to consult the built-in user manual or online resources for explanations of specific codes. Understanding these codes is crucial to addressing underlying issues effectively. Building familiarity with common error messages increases efficiency in troubleshooting and maintenance tasks.

Calibration Tips

Accurate calibration is vital for optimal machinery performance. Users should follow the provided guidelines within the software for calibrating their machines correctly. It is recommended to perform calibration checks regularly, especially after significant repairs or adjustments. This ensures that the equipment operates within the desired parameters. Gathering data before and after calibration can also help in tracking improvements or identifying ongoing issues.

Remote Support Services

Remote Installation Support (TeamViewer)

For users facing difficulties during installation or troubleshooting, remote support is available through TeamViewer. This service allows technicians to access and aid in resolving software issues directly on the user’s machine. To utilize this support, users simply need to initiate a session on TeamViewer, ensuring that they have stable internet access. This method proves beneficial for quickly addressing problems without the need for physical visits, saving time and enhancing problem resolution efficiency.

Accessing Technical Support

Users can access technical support services whenever needed. It is beneficial to have the software version and error codes ready when contacting support to facilitate a smoother resolution process. Regularly checking for updates and keeping abreast of software features can also assist in minimizing issues. Engaging with support enhances user experience and ensures effective utilization of all available resources.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

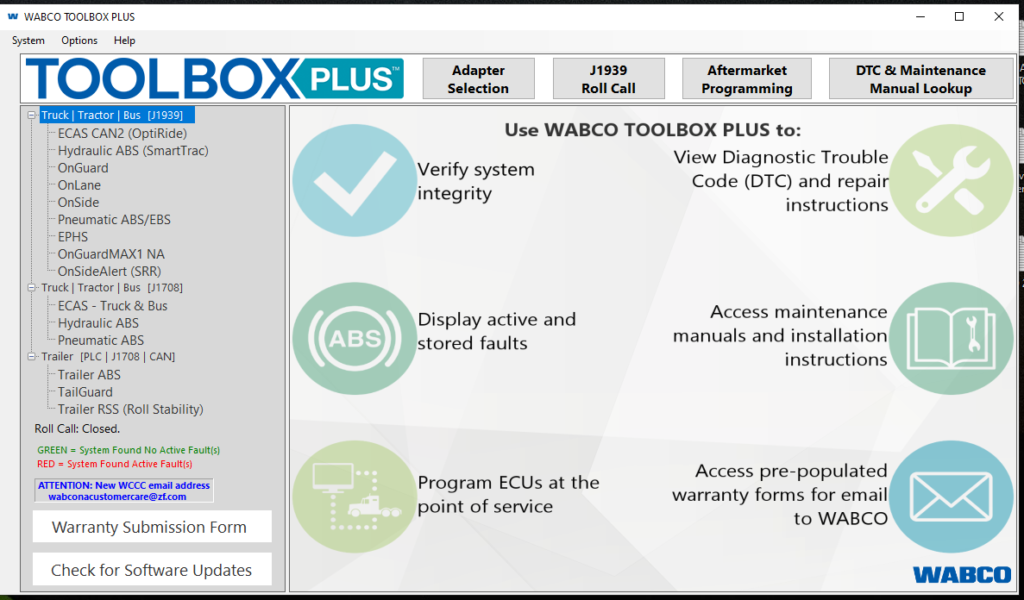

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![DOOSAN EDIA INDUSTRY FULL 2.3.5.8 [2023.06] is a comprehensive software solution designed for truck diagnostics and management. It offers advanced features that cater to the needs of fleet managers, technicians, and service centers. This software includes a user-friendly interface and compatibility with multiple systems. Additionally, remote installation support via TeamViewer enhances the user experience, making it an effective tool for improving operational efficiency.](https://ecmtrucks.com/wp-content/uploads/2024/08/566-1024x636.png)

Reviews

Clear filtersThere are no reviews yet.