CIRCUIT DESCRIPTION:

The speed sensors are variable reluctance devices which convert mechanical motion to an AC voltage. Each sensor consists of a wire coil wrapped around a pole piece that is adjacent to a permanent magnet. These elements are contained in a housing which is mounted adjacent to a rotating ferrous member. Two signal wires extend from one end of the housing and an exposed end of the pole piece is located at the opposite end of the housing. The permanent magnet produces lines of flux around the pole piece. As a ferrous object (a rib on the rotating clutch drum) approaches and passes through the gap at the end of the pole piece, an AC voltage pulse is induced in the wire coil. The TCM calculates the frequency of these AC pulses and converts it to a speed value. The AC voltage generated varies from 150mV at low speed to 15V at high speed. The signal wires from the sensor are formed as twisted pairs to cancel magnetically induced fields. The cable is also shielded to protect from voltage-related fields. Using two-wire differential input at the TCM eliminates noise from other sources.

ACTION TAKEN WHEN THE DTC SETS:

When DTC P0715 is active, the following conditions occur:

1. If the DTC sets while shift not in process, remains in current range.

2. If the DTC sets while shift is in process, complete shift and lock in that range.

3. The TCM forces Variable Modulated Main off.

4. DTC is stored in TCM history.

5. The CHECK TRANS light illuminates.

6. The TCM inhibits TCC engagement.

7. The TCM freezes shift adapts.

CONDITIONS FOR CLEARING THE DTC:

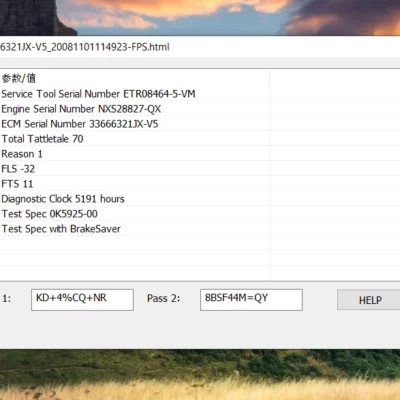

Use the diagnostic tool to clear the DTC from the TCM history. The TCM automatically clears the DTC from the TCM history if the vehicle completes 40 warm-up cycles without the DTC recurring.

DIAGNOSTIC AIDS:

DTC P0715 may be caused by:

1. W120 and/or W180 shorted to another wire in chassis harness or to ground.

2. W120 and/or W180 high resistance or open circuit.

3. Broken or defective connector assemblies allowing pushed back pins to short together.

4. Unlocked connectors, missing seal plugs allowing moisture in connectors.

5. Fatigued wires at speed sensor connectors (broken strands).

6. Incorrect pin crimps or expanded terminals.

7. Defective turbine shaft speed sensor.

8. Defective TCM.

9. Damaged rotating clutch drum.

10. Wire pair not twisted or not sufficiently twisted.

NOTE: Confirm that the speed sensor wiring consists of twisted pairs at the rate of 12 to 16 twists per 300 mm. These twists must extend the entire length of the wiring harness to within at least 50 mm of the speed sensor connector.

NOTE: OEM Transmission warranty, or the extended coverage for parts and labor, does not cover transmission or vehicle damage caused by drivelines that do not meet the OEM specifications.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![DOOSAN EDIA INDUSTRY FULL 2.3.5.8 [2023.06] is a comprehensive software solution designed for truck diagnostics and management. It offers advanced features that cater to the needs of fleet managers, technicians, and service centers. This software includes a user-friendly interface and compatibility with multiple systems. Additionally, remote installation support via TeamViewer enhances the user experience, making it an effective tool for improving operational efficiency.](https://ecmtrucks.com/wp-content/uploads/2024/08/566-300x186.png)

![DOOSAN EDIA-AS FULL STANDARD 2.4.0.7 [2023.06] is an essential diagnostic software designed for Doosan machinery. Released in June 2023, it enhances maintenance and troubleshooting processes for heavy equipment. This version offers improved functionality, user-friendly features, and unlimited licensing. It also provides remote installation support via TeamViewer, ensuring users can maximize their investment effectively.](https://ecmtrucks.com/wp-content/uploads/2024/08/11-400x400.png)

Reviews

Clear filtersThere are no reviews yet.