DIAGNOSTIC RESPONSE:

Default to turbine speed

CIRCUIT DESCRIPTION:

The speed sensors are variable reluctance devices which convert mechanical motion to an AC voltage. Each sensor consists of a wire coil wrapped around a pole piece that is adjacent to a permanent magnet. These elements are contained in a housing which is mounted adjacent to a rotating ferrous member. Two signal wires extend from one end of the housing and an exposed end of the pole piece is at the opposite end of the housing. The permanent magnet produces lines of flux around the pole piece. As a ferrous object (such as a gear tooth) approaches and passes through the gap at the end of the pole piece, an AC voltage pulse is induced in the wire coil. The Transmission Control Module (TCM) calculates the frequency of these AC pulses and converts it to a speed value. The AC voltage generated varies from 150mV at low speed to 15 volts at high speed. The signal wires from the sensor are formed as twisted pairs to cancel magnetically induced fields. The cable is also shielded to protect from voltage-related fields. Noise from other sources is eliminated by using two-wire differential inputs at the TCM.

CONDITIONS FOR RUNNING THE DTC:

1. Engine speed is above 600 rpm for more than 1 second.

2. Shifts complete and range attained not neutral.

CONDITIONS FOR SETTING THE DTC:

DTC P0726 is set when one of the following conditions occur:

1. Engine speed change greater than 600 rpm detected within a 0.15 second span.

2. Engine speed change greater than 650 rpm detected 5 or more times within a 2 second span.

ACTION TAKEN WHEN THE DTC SETS:

When DTC P0726 is active, the following conditions occur:

1. DTC P0726 is stored in the TCM history.

2. The TCM does not illuminate the CHECK TRANS light.

3. If ignition is OFF, then engine speed is set to 0. If turbine speed is greater than the engine speed calibration default value, then substitute turbine speed as engine speed.

CONDITIONS FOR CLEARING THE DTC/CHECK TRANS LIGHT:

Use the diagnostic tool to clear the DTC from the TCM history. The TCM automatically clears the DTC from the TCM history if the vehicle completes 40 warm-up cycles without the DTC recurring.

DIAGNOSTIC AIDS:

NOTE: When performing any resistance checks for troubleshooting, the current production sensors will have a nominal coil resistance value of 340 Ohms (± 25 Ohms) at an ambient temperature of 20°C (68°F), as compared to the former sensors which had a nominal resistance value of 300 Ohms (± 25 Ohms) at an ambient temperature of 20°C (68°F).

DTC P0726 may be caused by:

1. W139 and/or W159 shorted to another wire in chassis harness or to ground.

2. W139 and/or W159 high resistance or open circuit.

3. Broken or defective connector assemblies allowing pushed back pins to short together.

4. Unlocked connectors, missing seal plugs allowing moisture in connectors.

5. Fatigued wires at speed sensor connectors (broken strands).

6. Incorrect pin crimps or expanded terminals.

7. Defective engine speed sensor.

8. Defective TCM.

9. Wire pair not twisted or not sufficiently twisted.

NOTE: Inspect that the speed sensor wiring consists of twisted pairs at the rate of 12 to 16 twists per 300 mm. These twists must extend the entire length of the wiring harness to within at least 50mm of the speed sensor connector.

NOTE: Select SpeedSignalsDatalntegrityList in DPID configuration prior to connecting with the diagnostic tool in order to strip-chart close to real time speed signal data. Refer to the OEM Technician’s Library for additional information about DPID configuration and data collection.

Review applicable information in Control System and Transmission Specifications to find additional circuit specifications, system and connector diagrams, and troubleshooting tips.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

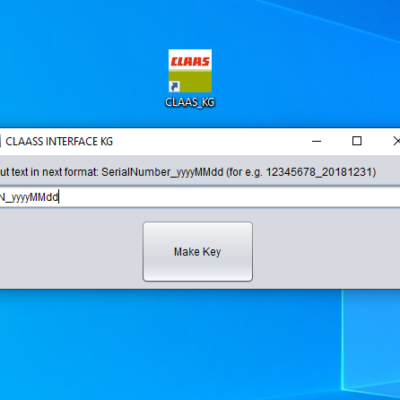

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The Doosan Diagnostic Tool DX22 Generator Engine 00.13 [2023.06] is essential for maintaining and diagnosing Doosan generators. It provides a comprehensive solution designed for efficiency and performance in heavy equipment. This tool enhances operational reliability by offering real-time monitoring and advanced diagnostic features. Its user-friendly interface simplifies troubleshooting, making it a valuable asset for technicians and maintenance teams in various industries.](https://ecmtrucks.com/wp-content/uploads/2024/08/3-300x227.png)

![The Doosan E-Doctor Industry Standard 2.4.0.7 [2023.06], released in June 2023, is a vital tool for diagnosing and maintaining heavy machinery. This software enhances efficiency and minimizes downtime by providing detailed engine diagnostics. Key features include multi-language support, an intuitive user interface, and the ability to conduct remote diagnostics. Compatibility with Windows 10 and 11 ensures seamless installation, while TeamViewer support facilitates remote assistance and installation for users.](https://ecmtrucks.com/wp-content/uploads/2024/08/55-1-400x400.png)

![JCB Service Master 4 Diagnostic Software is a powerful tool for professionals in the automotive and heavy machinery industry. With its easy-to-use interface, it provides a wide range of diagnostic and calibration functions for JCB machinery and engines. From construction to agricultural equipment, this software supports various JCB models, ensuring optimal performance and safety. It also offers programming capabilities and a language editing tool. Maximize your diagnostic efficiency and reliability with JCB Service Master 4 v21.4.2 [05.2021] from ecmtrucks.com.](https://ecmtrucks.com/wp-content/uploads/2024/01/JCB-servicemaster-4-400x400.webp)

Reviews

Clear filtersThere are no reviews yet.