Volvo Penta EPC 6 Offline VMware 2021: Benefits and Installation Guide

Volvo Penta EPC 6 Offline VMware 2021 is a vital tool for accessing parts and service information for Volvo Penta engines and equipment. It enables users to efficiently manage and identify spare parts without needing an internet connection. This software is designed for ease of use in various industrial and marine sectors. The following sections will detail the installation process, offline capabilities, and how it integrates into existing systems.

Understanding Volvo Penta EPC 6

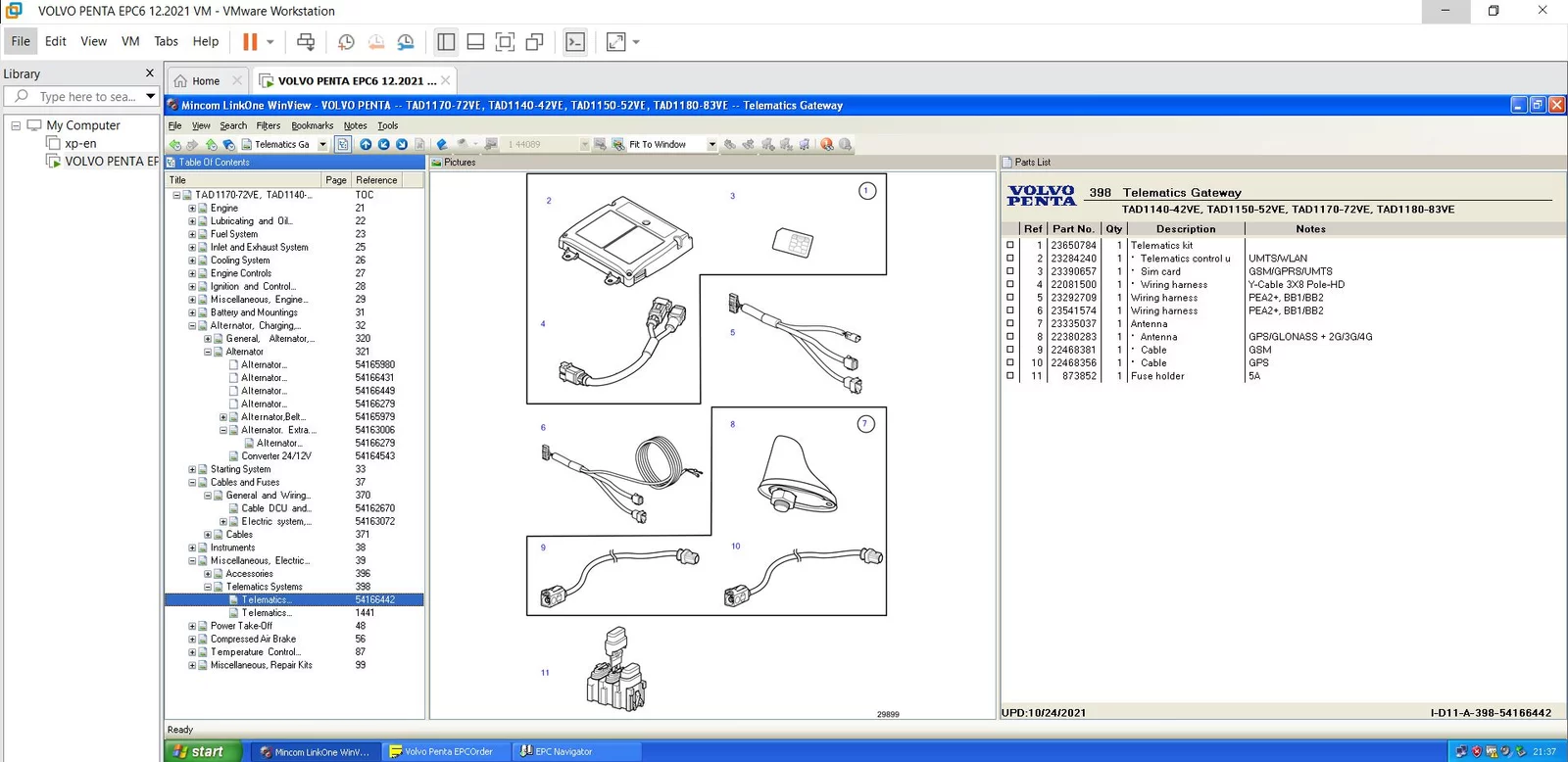

The Volvo Penta Electronic Parts Catalog (EPC) 6 offers a comprehensive solution for users to access detailed parts information related to Volvo Penta engines and equipment. This section explores its key features and benefits, comparisons with prior versions, and its significance in different sectors.

Key Features and Benefits

The Volvo Penta EPC 6 comes packed with various features designed to enhance user experience. Some of the notable benefits include:

- Instant Access to Information: Users can quickly retrieve information relevant to engine parts and specifications, streamlining the repair and maintenance process.

- Detailed Diagrams: The catalog provides visual representations of parts and assembly, making it easier for technicians to identify components.

- Multi-Language Support: The interface accommodates multiple languages, catering to a global audience and facilitating better communication across diverse user bases.

- Robust Search Functionality: The search tools allow users to filter results via part numbers, descriptions, and other criteria, ensuring efficient navigation through the catalog.

EPC 6 vs. Previous Versions

Volvo Penta EPC 6 boasts significant improvements over its predecessors. It features:

- Enhanced User Interface: The layout and functionality have been optimized for better usability, minimizing the learning curve for new users.

- Improved Performance: The software runs more efficiently, allowing for faster loading times and smoother navigation through extensive databases.

- Greater Integration Capabilities: This version offers better compatibility with various operating systems and third-party applications, enhancing overall workflow.

Role in Industrial and Marine Sectors

The Volvo Penta EPC 6 serves as a crucial tool in both industrial and marine sectors. In industrial settings, it supports maintenance teams who rely on precise and timely parts information to keep operations running smoothly. Similarly, in marine applications, effective parts management is vital for ensuring vessel safety and performance. This software aids ship operators and mechanics, providing access to necessary documentation and specifications, ultimately contributing to reduced downtime and increased efficiency.

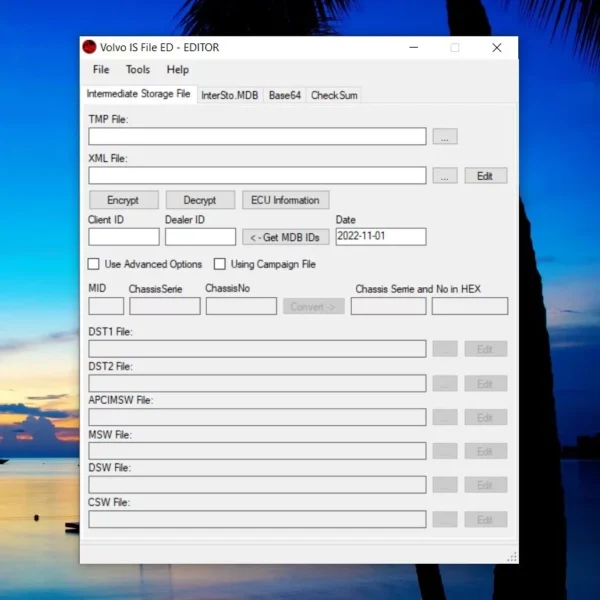

Installation Process on VMware

The installation process for Volvo Penta EPC 6 on VMware is straightforward, yet requires meticulous attention to system specifications and steps to ensure functionality. Here’s a detailed guide to walk through the process.

System Requirements

Before beginning the installation, it is crucial to verify that the system meets the necessary requirements. A compatible system ensures optimal performance and usability of the software.

- Operating System: Windows XP, 7, 8, or 10, as the software is designed to operate within these environments.

- RAM: A minimum of 4 GB recommended to ensure smooth operation.

- Processor: At least a dual-core CPU for efficient processing speed.

- Storage: A minimum of 20 GB free hard drive space is required to accommodate the software and its data.

Step-by-Step Installation Guide

Following these steps will help ensure a successful installation of the software in a VMware environment.

Download and Prepare Files

The first step involves obtaining the installation file. Download the compressed file from a reliable source. After downloading, ensure it is saved in an accessible location on your computer.

Setting Up the Virtual Machine

Using VMware, create a new virtual machine. Configuring the machine needs to be done according to the system requirements previously mentioned. Ensure adequate resources are allocated to the virtual machine for optimal performance.

Installing and Configuring the Software

Once the virtual machine is set up, proceed with the installation. Follow these sub-steps:

- Navigate to the location of the downloaded files and extract them using a suitable tool like WinRAR.

- Begin the installation by executing the installer found in the extracted folder.

- Adhere to on-screen prompts, such as providing necessary activation codes or serial numbers as prompted.

Common Installation Issues and Solutions

Users may encounter various issues during the installation process. Identifying and addressing these common problems can facilitate a smoother setup.

- Insufficient Permissions: Running the installer as an administrator can help resolve permissions-related issues.

- Incompatible Virtual Hardware: If the virtual machine’s hardware settings are not compliant with software requirements, adjustments may be necessary.

- Corrupted Download: If installation fails, consider re-downloading the installation files to ensure they are not corrupted.

Offline Access Capabilities

Offline access capabilities allow users to retrieve crucial information without the need for a continuous internet connection. This feature ensures that vital data is always accessible, enhancing efficiency in managing equipment and parts.

Advantages of Offline Access

Offline access to the parts catalog offers several key benefits for users in various industries. These advantages include:

- Availability Anytime, Anywhere: Users can access the catalog at any location, even in remote areas lacking internet connectivity.

- Speed and Efficiency: Eliminates delays caused by slow internet connections, allowing for quicker decision-making and repairs.

- Data Security: Storing information locally reduces the risk of data breaches associated with online environments.

Navigating the Parts Catalog

Users can easily navigate the parts catalog to find essential components using various tools. The catalog is designed for seamless navigation, ensuring efficient access to required information.

Searching for Parts

The search functionality within the offline catalog allows users to input part numbers or descriptions to quickly locate necessary items. Users can utilize advanced filtering options to refine their search results based on specific criteria:

- Part type

- Component compatibility

- Manufacturer details

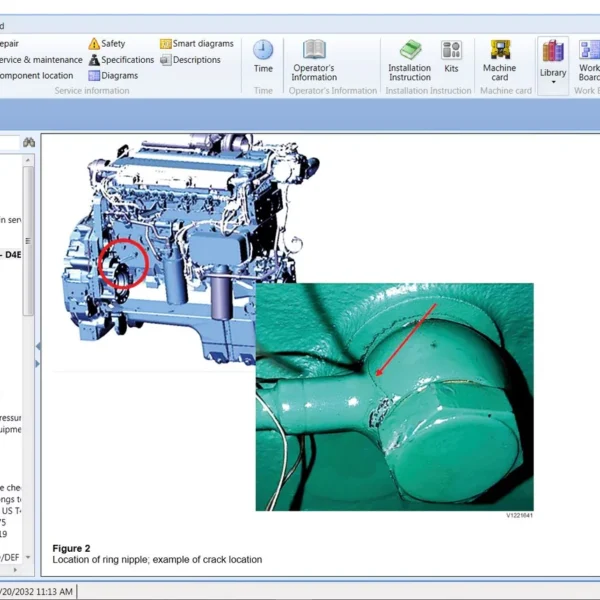

Using Diagrams and Lists

The catalog features visual aids such as diagrams and lists, which enhance the user experience. Diagrams provide clear visuals of part locations, while lists outline specifications:

- Parts Diagrams: Detailed illustrations showing parts arrangement and connections facilitate easier installations and maintenance.

- Parts Lists: Comprehensive lists enumerate available parts along with their specifications, enabling informed procurement decisions.

Maintaining Updated Information Offline

Keeping data current while working offline presents unique challenges. Users can manage updates effectively with the software’s built-in functionality:

- Regular Updates: Users can schedule regular updates when an internet connection is available, ensuring access to the latest parts and information.

- Backup Options: Multiple backup strategies are utilized to safeguard valuable information, allowing for recovery in case of data loss.

Utilizing the EPC for Parts Replacement

The Volvo Penta EPC is a crucial resource for effectively managing parts replacement. It streamlines the process, ensuring that users can locate, identify, and replace components efficiently.

Finding Spare Parts

Identifying spare parts through the EPC is simplified with its robust search capabilities. Users can search for components by:

- Part number

- Description

- Specifications and dimensions

- Machine model and year

This multi-faceted approach allows for precise identification of required parts, minimizing downtime and enhancing maintenance efficiency. The database’s extensive inventory ensures that users are equipped with accurate information for effective repairs.

Using Diagrams for Accurate Replacements

The EPC provides detailed diagrams that illustrate how components fit within the overall system. These diagrams serve several important purposes:

- Visual guidance for locating parts within complex assemblies

- Clear representation of how parts interact with one another

- Assistance in understanding installation and replacement processes

Utilizing diagrams reduces the risk of errors during the replacement process. By having access to visual aids, technicians can verify the correct placement of components, leading to higher quality repairs and reduced chances of repeated issues.

Integrating with Existing Maintenance Systems

For organizations utilizing comprehensive maintenance systems, the EPC can be seamlessly integrated to enhance operational capabilities. Key aspects of this integration include:

- Direct data input into maintenance management software, allowing for streamlined workflow

- Real-time updates on parts availability, ensuring that stock levels are managed efficiently

- Historical data tracking, which can inform future purchasing and maintenance decisions

This level of integration enables businesses to maintain a holistic approach to equipment management, ensuring that parts replacement is not only efficient but also part of a larger strategy for sustainability and operational excellence.

User Experience and Interface

The user experience and interface design of Volvo Penta EPC 6 Offline VMware 2021 play a crucial role in ensuring efficiency and ease of use for technicians and operators alike.

Multi-Language Support

The software offers extensive multi-language support, making it accessible to a global audience. Users can select their preferred language from an array of options, including English, Spanish, German, French, Japanese, and Russian. This feature is vital for organizations operating in diverse regions or employing a multilingual workforce. By allowing users to operate the interface in their native language, Volvo Penta enhances comprehension and reduces the likelihood of errors during parts identification and ordering.

User-Friendly Navigation Tips

Efficient navigation is key to maximizing the utility of the EPC software. Users can benefit from several navigation tips designed to streamline their experience:

- Utilize the Search Function: The search bar enables quick access to parts by entering relevant keywords, such as part numbers or descriptions. This minimizes downtime while searching.

- Leverage Filters: Applying filters helps narrow down search results, allowing users to quickly find exactly what they need in a vast catalog.

- Bookmark Frequently Used Sections: Frequent users can bookmark essential sections of the catalog for immediate access during their workflow.

Customizing the Interface for Specific Needs

Customization options in the Volvo Penta EPC allow users to tailor the software to meet their specific operational needs. Several customization features facilitate this flexibility:

- Adjustable Display Settings: Users can modify aspect ratios and layouts to enhance visibility and comfort based on their workspace.

- Personalized User Profiles: Creating profiles enables users to save their settings, preferences, and commonly accessed materials for rapid retrieval.

- Integration Capabilities: The platform supports various integrations with existing maintenance systems, allowing for a cohesive workflow. This capability ensures that users can manage information seamlessly across multiple tools.

Troubleshooting and Support

Effective troubleshooting and support are essential for maintaining seamless operation. Users may encounter various challenges, but numerous resources and communities can provide assistance. This section outlines available support networks and common queries that users might face.

Accessing Support Networks

Finding help when facing issues is crucial for efficient usage of the software. Below are two primary avenues for support:

Online Forums and Communities

Online forums are valuable resources where users can connect with peers. These platforms allow individuals to share their experiences, seek advice, and provide solutions. Some popular forums specifically cater to Volvo Penta users and mechanics. Members often discuss troubleshooting techniques, provide insights into known issues, and share best practices.

Official Support Channels

Official support channels offer direct assistance from the manufacturer. Users can access technical documentation, submit support tickets, or consult the knowledge base for detailed guides. Having access to verified support ensures that users receive accurate information tailored to specific software concerns.

Common User Queries and FAQs

Many users encounter similar issues, leading to a range of frequently asked questions. Understanding these common queries can expedite solutions and enhance user experience.

Software Activation Issues

Activation problems may arise due to several reasons, including incorrect keys or conflicts with security settings. Users should double-check the entered serial number and ensure that no other application is interfering with the activation process. If issues persist, consulting official support may be necessary.

Navigational Challenges

Some users might find navigating the software interface challenging. Common navigation issues include difficulty locating specific parts or using the search functionality effectively. Users are encouraged to familiarize themselves with the interface layout and leverage available help guides. Participating in forums can also provide tips and tricks from experienced users.

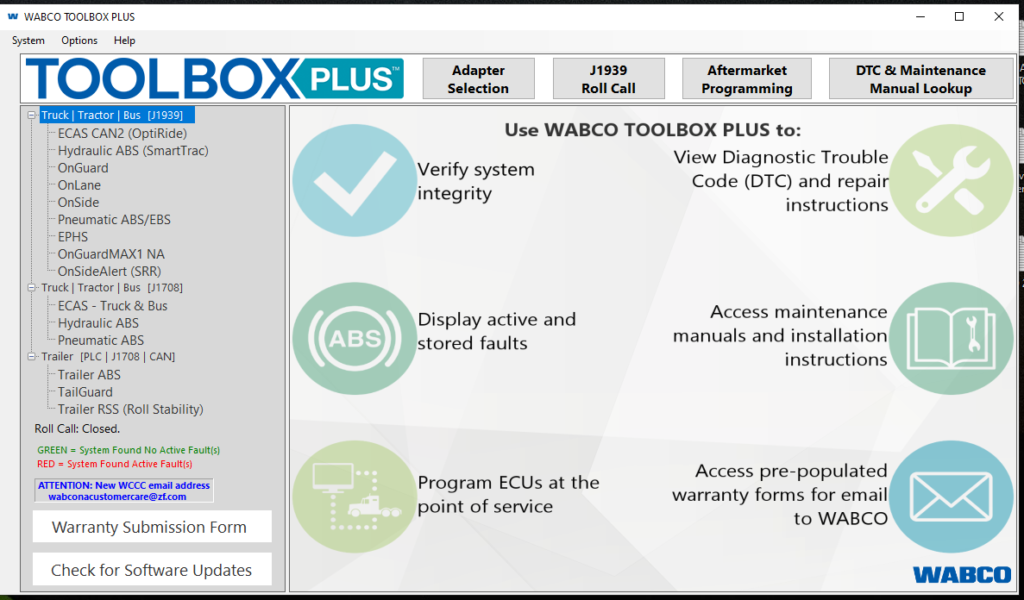

Integration with Volvo Penta Services

The integration of Volvo Penta EPC 6 with Volvo Penta services enhances operational efficiency and provides users with a seamless experience when managing their equipment. This section explores the various aspects of this integration, focusing on diagnostic tools, installation service collaboration, and future updates.

Linking with Diagnostic Tools

Volvo Penta EPC 6 seamlessly connects with diagnostic tools, enabling users to perform in-depth assessments of engine performance and functionality. This linkage allows mechanics and service providers to:

- Retrieve real-time diagnostics from the engine.

- Analyze data patterns for maintenance planning.

- Access troubleshooting guidelines tailored to specific engine issues.

- Utilize performance metrics for performance enhancements.

The ability to interface with diagnostic tools means that users can stay proactive about engine maintenance, mitigating potential issues before they escalate. This capability significantly reduces downtime and increases overall reliability.

Collaboration with Installation Services

Integration with installation services positions Volvo Penta EPC 6 as a crucial element in the life cycle of Volvo engines and machinery. This collaboration ensures that:

- Installation services utilize up-to-date specifications from the EPC for accurate setups.

- Service technicians receive consistent training based on the latest software capabilities.

- Users are informed about the installation processes involved, maximizing equipment performance from the outset.

This partnership helps streamline the installation and ensures all components are thoroughly documented and matched correctly to their respective systems.

Future Updates and Compatibility

As technology evolves, the integration of Volvo Penta EPC 6 with existing services ensures that users remain at the cutting edge of technical advancements. Future updates are crucial for:

- Maintaining compatibility with new Volvo engines and machinery.

- Expanding the catalog with new parts and services as they become available.

- Enhancing user experience through updated interfaces and functionalities.

Continuous improvement is key in the fast-paced industrial sector, and this forward-looking approach guarantees that users are equipped with the tools needed for effective maintenance and management of their Volvo Penta equipment.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.