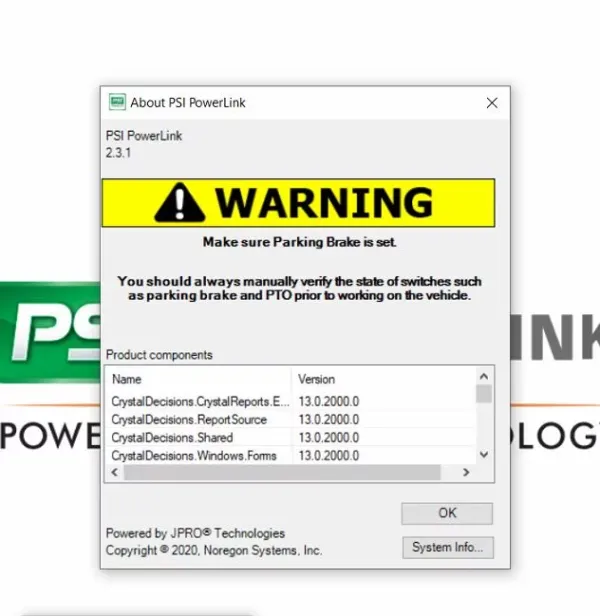

PSI Powerlink 2 3 1: Revolutionizing Heavy-Duty Vehicle Diagnostics

PSI Powerlink 2.3.1 is an advanced diagnostic tool designed for heavy-duty vehicles equipped with PSI engines. It provides real-time diagnostics, enabling technicians to effectively monitor engine performance. This software includes key features such as trouble code reading, performance monitoring, and calibration information. PSI Powerlink 2.3.1 enhances maintenance efficiency and minimizes downtime for fleet operations.

Table of Contents

ToggleUnderstanding PSI Powerlink 2.3.1

This section delves into the essence of PSI Powerlink 2.3.1, focusing on its primary functions and advantages within the realm of heavy-duty vehicle diagnostics.

What is PSI Powerlink?

PSI Powerlink is a cutting-edge software designed exclusively for the diagnosis and performance monitoring of heavy-duty vehicles equipped with PSI engines. It leverages advanced technology to enhance mechanics’ ability to swiftly troubleshoot engine issues and streamline maintenance processes.

Key Features and Benefits

This software offers a variety of features tailored to meet the specific needs of technicians working with heavy-duty engines. Here are some of its most notable advantages:

Real-Time Diagnostics

One of the standout features of PSI Powerlink 2.3.1 is its capacity for real-time diagnostics. Technicians can access critical information instantaneously, allowing them to identify issues as they arise, which significantly aids in minimizing unplanned downtime.

Engine Compatibility

The software is designed to be fully compatible with a range of PSI engines, making it a versatile tool for various maintenance operations. This compatibility ensures that users can effectively diagnose issues across different vehicle types utilizing PSI technology.

Ease of Use

PSI Powerlink 2.3.1 prioritizes user experience by providing an intuitive interface. The streamlined setup and operation empower technicians, even those with limited technological expertise, to efficiently navigate the software and utilize its diagnostic capabilities.

Installation and Setup

Proper installation and setup are crucial for optimizing the use of diagnostics software. The following sections outline the essential steps to ensure a smooth installation process for PSI Powerlink 2.3.1.

Downloading the Software

The first step in the installation process is downloading the PSI Powerlink 2.3.1 software. The software can typically be obtained from the manufacturer’s website or authorized distributors, ensuring that users acquire the latest version available.

System Requirements

Ensuring that the system meets the necessary requirements is vital for the software’s functionality. Below are the key specifications needed for a seamless experience.

Supported Operating Systems

- Windows 10 (64-bit)

- Windows 11 (64-bit)

Hardware Specifications

- Minimum of 4 GB RAM

- 500 MB of available hard drive space

- USB port for hardware connection

Installation Process

Once the software has been downloaded and the system requirements are confirmed, users can proceed to the installation process.

Unpacking the .rar File

The downloaded file usually comes in a .rar format. To unpack the file, users should utilize compatible software such as WinRAR or 7-Zip. Follow the prompts to extract the contents to a designated folder on the computer.

Initial Configuration

After unpacking the installation files, the user can initiate the installation process. Clicking on the setup file will start the installation wizard, which will guide through the steps needed. Configurations such as selecting the installation directory and agreeing to the terms of service are required. Completing these steps will ready the software for operation.

Using PSI Powerlink for Diagnostics

PSI Powerlink serves as an essential tool for diagnosing issues in heavy-duty vehicles equipped with PSI engines. Its capabilities facilitate a thorough understanding of engine performance and problems.

Reading Trouble Codes

One of the primary functions of PSI Powerlink is reading trouble codes. This feature allows technicians to access specific OEM codes related to PSI engines. Accurate reading of these codes streamlines the diagnostic process.

- Identifying error messages that signal potential issues.

- Providing detailed descriptions of codes to aid in problem-solving.

- Enabling swift decision-making based on error severity.

Monitoring Engine Performance

Real-time monitoring of engine performance is another critical function of PSI Powerlink. This capability offers insights into various parameters that affect vehicle efficiency.

- Tracking engine temperature and pressure levels.

- Assessing fuel consumption to optimize performance.

- Detecting abnormal changes in performance metrics quickly.

Calibration and CVN Information

The tool also provides essential details regarding calibration and the Calibrated Vehicle Number (CVN). This functionality is crucial for ensuring compliance with industry standards.

- Offering data on engine settings and adjustments.

- Facilitating regulatory compliance checks through CVN details.

- Assisting in preventive measures to maintain pre-defined performance levels.

Comparison with Other Diagnostic Tools

In the competitive landscape of diagnostic tools for heavy-duty vehicles, PSI Powerlink distinguishes itself through specialized functionalities and user experience. This section explores how it stacks up against other popular diagnostic solutions.

PSI Powerlink vs. Allison DOC

Allison DOC is a widely used diagnostic tool focused on Allison transmissions. While it excels in that niche, PSI Powerlink offers a broader compatibility with PSI engines. Key differences include:

- Engine Focus: PSI Powerlink specializes in PSI engines, ensuring more accurate diagnostics for those specific vehicles.

- User Interface: PSI Powerlink boasts an intuitive interface that allows for quicker navigation and easier interpretation of diagnostics.

- Real-Time Data: PSI Powerlink provides real-time data analytics, which is crucial for immediate troubleshooting.

PSI Powerlink vs. Bendix ACom Pro

Bendix ACom Pro is excellent for brake system diagnostics. However, it is less versatile when it comes to overall engine diagnostics. Key considerations include:

- Diagnostic Range: PSI Powerlink can analyze a wider array of engine conditions beyond brake systems.

- Code Reading: PSI Powerlink features specialized code reading tailored for PSI engines, making it more effective for relevant issues.

- Performance Monitoring: The ability to continuously monitor engine performance sets PSI Powerlink apart.

Unique Advantages

PSI Powerlink comes with distinct advantages that enhance its value proposition. These include:

- Cost Efficiency: By minimizing downtime through efficient diagnostics, it saves money on repairs.

- Ongoing Support: Continuous software updates ensure the tool remains compatible with evolving engine technologies.

- Training Resource: The software serves as an educational asset for technicians, improving their diagnostic skills.

Support and Updates

Comprehensive support and timely updates are essential for maximizing the effectiveness of diagnostic tools. Proper assistance ensures that users can fully utilize the software’s capabilities, while software updates maintain compatibility and improve functionality.

Customer Support Options

Customer support for PSI Powerlink is designed to address users’ needs efficiently. Various options are available for users seeking assistance.

Online Resources and Videos

PSI Powerlink offers a wealth of online resources that include:

- Tutorial videos that cover installation and operation.

- FAQs addressing common user issues.

- User manuals that provide step-by-step guidance on using the software effectively.

Contact Support

For personalized assistance, a dedicated support team is available to help troubleshoot and resolve specific issues. Users can reach out for help through various channels to ensure swift responses to their inquiries.

Software Updates

Regular software updates are crucial for maintaining the performance and reliability of PSI Powerlink. These updates often include new features, bug fixes, and enhancements that improve user experience.

Importance of Staying Updated

Keeping the software up to date is vital for the following reasons:

- Enhances compatibility with the latest hardware and operating systems.

- Ensures access to new diagnostic capabilities and features.

- Makes sure any known issues are promptly addressed and resolved.

How to Update

Updating the PSI Powerlink software is a straightforward process typically involving:

- Notifying users of available updates via the software interface.

- Providing a seamless download mechanism for the latest version.

- Guiding users through the installation process to replace outdated files with updated versions.

Best Practices for Technicians

Implementing best practices when using diagnostic tools enhances efficiency and effectiveness in vehicle maintenance. Technicians can benefit from strategies that streamline diagnostics, troubleshoot issues, and maintain machinery optimally.

Troubleshooting Tips

Effective troubleshooting involves a systematic approach to problem identification. Key strategies include:

- Check Codes Thoroughly: Always start by reading and documenting all trouble codes. This provides a comprehensive view of potential issues.

- Use Diagnostic Data: Leverage real-time data and performance metrics to pinpoint underlying problems beyond just codes.

- Follow Wiring Diagrams: Refer to accurate wiring diagrams to ensure all connections are sound and problem areas are identified.

Maximizing Efficiency

To optimize the diagnostic process and minimize downtime, consider the following approaches:

- Stay Organized: Keep the workspace organized to easily access tools and documentation, reducing time lost searching for equipment.

- Regular Training: Invest in ongoing training to stay updated on the latest features and updates of the software.

- Plan for Diagnoses: Always prepare for diagnostics by analyzing previous maintenance records and understanding the vehicle’s history.

Maintenance Strategies with PSI Powerlink

Implementing effective maintenance strategies will prolong the life of heavy-duty vehicles. Important practices involve:

- Routine Diagnostics: Schedule regular diagnostic tests to identify and rectify issues before they escalate.

- Documentation: Maintain accurate records of all diagnostics and repairs to facilitate future servicing.

- Proactive Monitoring: Utilize the tool’s monitoring capabilities to keep an eye on performance trends, allowing for proactive maintenance decisions.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

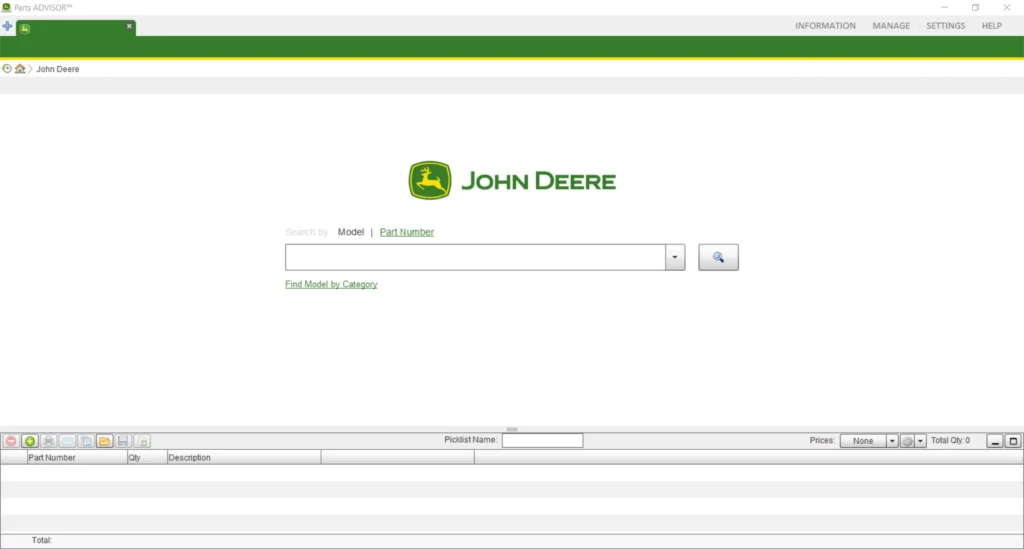

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR