KOHLER EFI DIAGNOSTIC SYSTEM 2.11.0013: Optimize Heavy Machinery Performance

The KOHLER EFI Diagnostic System 2.11.0013 is designed to enhance the performance of heavy machinery and trucks. It offers advanced troubleshooting capabilities, real-time data monitoring, and compatibility with various equipment. This system streamlines the diagnosis process, making it easier to identify and resolve issues. Installation can be done remotely via TeamViewer, ensuring a quick and efficient setup.

Understanding the KOHLER EFI Diagnostic System

This section delves into the fundamental aspects of the KOHLER EFI Diagnostic System, highlighting its technology and features that cater to users in heavy machinery sectors.

Overview of KOHLER EFI Technology

KOHLER EFI technology represents a significant advancement in engine management. Utilizing electronic fuel injection enhances overall engine performance and efficiency. This system offers precise fuel delivery, which helps to optimize combustion and reduce emissions.

The integration of KOHLER EFI technology into diagnostic systems allows for thorough monitoring and analysis, ensuring that machinery operates at peak performance. With this technology, users can monitor engine health, track performance metrics, and make informed maintenance decisions.

Key Features of the System

This diagnostic system is packed with features designed to assist users in managing heavy machinery effectively.

Real-Time Data Monitoring

One standout characteristic is its ability to provide real-time data monitoring. This feature allows users to receive immediate feedback on engine performance metrics, such as temperature, pressure, and fuel levels. By monitoring these parameters, operators can identify potential issues before they lead to costly repairs.

- Immediate alerts for irregular readings

- Continuous performance tracking

- Enhanced visibility into fuel efficiency

Compatibility with Heavy Machinery

An essential aspect of the KOHLER EFI Diagnostic System is its wide compatibility range with various heavy machinery. This ensures that the system can be integrated into numerous equipment models without extensive modifications.

Moreover, compatibility facilitates seamless updates and software enhancements, ensuring that users have the latest features and diagnostics without needing to invest in new hardware.

Advanced Troubleshooting Capabilities

The advanced troubleshooting capabilities of the diagnostic system simplify the process of diagnosing and resolving engine issues. Equipped with comprehensive error code libraries, users can quickly identify malfunctions and implement effective solutions.

- Detailed error codes for specific problems

- Guidelines for basic troubleshooting

- Tools for in-depth analysis of engine performance

Installation Process for the Diagnostic System

The installation process for the diagnostic system is crucial for ensuring optimal performance and reliability. This section outlines the necessary requirements and provides a comprehensive installation guide.

Installation Requirements

Before initiating the installation, certain prerequisites must be met. These requirements ensure that the diagnostic system operates effectively. The following items should be prepared:

- A compatible computer with sufficient hardware specifications.

- The latest version of the diagnostic software installed on the computer.

- Stable internet connection for remote installation.

- Access to TeamViewer software for remote assistance.

- A suitable environment for connecting the heavy machinery or truck to ensure safety and efficacy.

Step-by-Step Installation Guide

The following step-by-step process outlines how to properly install the diagnostic system. Adhering to these instructions will facilitate a smooth setup and ensure functionality.

Preparing Your Equipment

Before installation begins, ensure that all necessary equipment is on hand and in working order. Conduct the following preparations:

- Check the computer’s compatibility with the software.

- Verify that all cables and connectors are functioning properly.

- Update the operating system to the latest version to avoid compatibility issues.

- Organize the work area to reduce clutter and enhance productivity.

Installing via TeamViewer

Installation can be completed remotely using TeamViewer. This approach allows for real-time assistance, making the process efficient. Follow these steps:

- Launch TeamViewer on both the support computer and the installation computer.

- Share the TeamViewer access ID and password with the technician.

- Once connected, follow the technician’s instructions to install the diagnostic software.

Post-Installation Checks

After the installation has been completed, it is important to verify that the system is working as intended. Conduct the following checks:

- Open the diagnostic software and confirm that it launches without issues.

- Run a basic diagnostic test to ensure the system collects data from the machinery correctly.

- Check for any error messages or notifications that may indicate a problem.

- Ensure that all features, such as real-time data monitoring, are functioning properly.

How to Use the KOHLER EFI Diagnostic System

The KOHLER EFI Diagnostic System offers a user-friendly platform for efficiently monitoring and diagnosing heavy machinery and trucks. Here are essential guidelines for navigating the interface and performing diagnostic tests.

Navigating the User Interface

The user interface of the KOHLER EFI Diagnostic System is designed to provide an intuitive experience. Upon launching the software, users are greeted with a clear dashboard displaying various options. Key components include:

- Dashboard Overview: Quick access to critical system parameters.

- Menu Bar: Contains all necessary tools for navigation and functionality.

- Status Indicators: Visual cues for system health and operational status.

Familiarization with these elements aids users in quickly finding diagnostic tools and features. Each section provides a guided approach, ensuring users can navigate seamlessly through the program.

Performing Diagnostic Tests

Conducting diagnostic tests is a vital function of the system, enabling the detection of issues and performance monitoring. The process involves several steps to ensure comprehensive evaluation.

Analyzing System Performance

Start by selecting the ‘Performance Analysis’ option from the dashboard. This feature provides insights into various operational parameters:

- Fuel Efficiency Metrics: Assess fuel consumption rates in real-time.

- Engine Temperature Monitoring: Keep an eye on temperature fluctuations.

- RPM Levels: Analyze engine performance under load conditions.

Reviewing these metrics helps optimize machinery operation and can flag potential issues before they escalate.

Detecting and Resolving Errors

The diagnostic system excels in identifying faults. After initiating a diagnostic test, the program scans for error codes in the machinery and provides detailed descriptions. Common error types include:

- Electrical Faults: Issues related to sensor connectivity or wiring.

- Mechanical Failures: Problems detected in component integrity.

- Software Glitches: Anomalies within the operating system software.

Each error is accompanied by recommended solutions, enhancing troubleshooting efficiency.

Reporting and Data Logging

Utilizing the reporting features provides a comprehensive record of diagnostics performed. Users can generate reports that include:

- Error Codes and Resolutions: Documenting findings for future reference.

- Performance Trends: Tracking improvements or declines over time.

- Maintenance Recommendations: Suggested preventative measures based on tests conducted.

Data logging not only assists with compliance but serves as invaluable information for future diagnostics and reviews of machinery functionality.

Common Issues and Troubleshooting

Troubleshooting the KOHLER EFI Diagnostic System entails recognizing and resolving common issues that users might encounter. Understanding error codes and connection challenges is essential for maintaining effective operation.

Understanding Error Codes

Error codes provide critical insights into the system’s functioning. Each code corresponds to a specific issue, allowing users to identify problems quickly. Familiarity with these codes can significantly enhance troubleshooting efforts. Common error codes may include:

- Error Code 101: Indicates a communication failure between the diagnostic tool and the ECU.

- Error Code 202: Signals a malfunction in the fuel system, often related to fuel pressure or injectors.

- Error Code 303: Reflects issues with the electronic throttle control system.

Understanding these codes allows users to take appropriate actions, whether that involves checking connections or replacing faulty components.

Resolving Connection Issues

Connection problems can hinder the effective use of the diagnostic system. Such issues may arise from network settings, software incompatibilities, or physical connection faults. Addressing these challenges is crucial for smooth operation.

Troubleshooting TeamViewer Connections

For users who rely on TeamViewer for remote diagnostics, connection issues can be particularly frustrating. Common steps to troubleshoot include:

- Verifying that both devices are connected to the internet.

- Ensuring that the TeamViewer application is installed and updated on both ends.

- Checking that the session ID and password are correctly entered.

- Restarting the TeamViewer application to refresh the connection.

By following these steps, many connection issues can be resolved efficiently.

Hardware Compatibility Solutions

Hardware compatibility can also affect the functionality of the KOHLER EFI Diagnostic System. Users may encounter issues if the diagnostic tool is not compatible with specific machinery models. To mitigate these problems:

- Review the system requirements outlined in the user manual.

- Ensure that all cables and connectors are in good condition and match the specifications required for the machinery.

- Consult with customer support for assistance in verifying compatibility.

Implementing these solutions can significantly reduce hardware-related complications and enhance system performance.

Enhancing the Performance of Heavy Machinery

Improving the performance of heavy machinery involves a combination of routine maintenance and strategic optimization techniques. These measures ensure that equipment operates efficiently, prolongs its lifespan, and enhances overall productivity.

Routine Maintenance Tips

Regular maintenance is crucial for the longevity and efficiency of heavy machinery. Implementing a consistent maintenance schedule can prevent unexpected breakdowns and costly repairs.

- Inspect fluid levels regularly, including oil, coolant, and hydraulic fluid.

- Check filters and replace them as needed to maintain optimal performance.

- Keep components clean from dirt and debris to minimize wear and tear.

- Examine belts and hoses for signs of wear, replacing them promptly to avoid malfunctions.

- Perform routine lubrication on moving parts to reduce friction and enhance efficiency.

Performance Optimization Techniques

Optimizing machinery performance can lead to significant improvements in operational efficiency and cost-effectiveness. Various strategies can be employed to achieve this goal.

Fuel Efficiency Improvements

Fuel consumption is a major operating cost for heavy machinery. Implementing practices to enhance fuel efficiency can yield substantial savings. Consider the following measures:

- Regularly calibrate and tune engines for optimal combustion.

- Utilize high-quality fuels and lubricants to improve performance.

- Train operators on efficient driving techniques, emphasizing smooth acceleration and deceleration.

- Minimize idling time to reduce fuel wastage.

- Ensure proper tire pressure to enhance traction and fuel economy.

Extending Machinery Lifespan

Maintaining and optimizing machinery not only enhances performance but also extends its operational lifespan. Implementing preventative measures can greatly reduce wear and prolong service life:

- Schedule regular inspections to identify and address potential issues before they escalate.

- Follow the manufacturer’s guidelines for maintenance and service intervals.

- Use diagnostic tools to monitor machine health and performance metrics.

- Invest in quality replacement parts to maintain reliability and performance.

- Encourage a culture of care and responsibility among operators to promote proper handling of equipment.

FAQs About KOHLER EFI Diagnostic System

This section addresses frequently asked questions regarding the KOHLER EFI Diagnostic System. Here, users can find answers to common inquiries as well as details about technical support and available resources.

Common User Questions

Users often seek clarification on various aspects of the KOHLER EFI Diagnostic System. Some of the most common questions include:

- What types of machinery are compatible with the KOHLER EFI Diagnostic System?

- How does the real-time data monitoring feature work?

- Can the system help identify specific faults in machinery?

- Is training required to effectively use the diagnostic tools?

- What maintenance is needed for the diagnostic system?

Understanding the capabilities and functions of the diagnostic system can enhance user experience and improve machinery performance.

Technical Support and Resources

For those requiring assistance beyond the FAQs, several technical support options are available. Accessing support can be crucial for troubleshooting and resolving any issues that may arise during usage.

Accessing Customer Support

The KOHLER EFI Diagnostics team provides customer support through various channels. Users can visit the official website to find contact forms and other communication methods. It is important to gather relevant information about the issue prior to reaching out, which helps streamline the support process.

Utilizing Online Resources and Manuals

A wealth of knowledge can be found online regarding the KOHLER EFI Diagnostic System. Users can explore manuals and guides that delve into detailed features of the diagnostic tools. These resources cover:

- Installation instructions

- User interface navigation

- Common troubleshooting steps

- FAQs addressing typical concerns

Accessing these materials can significantly enhance the user experience and efficiency of the diagnostic system, providing vital information at one’s fingertips.

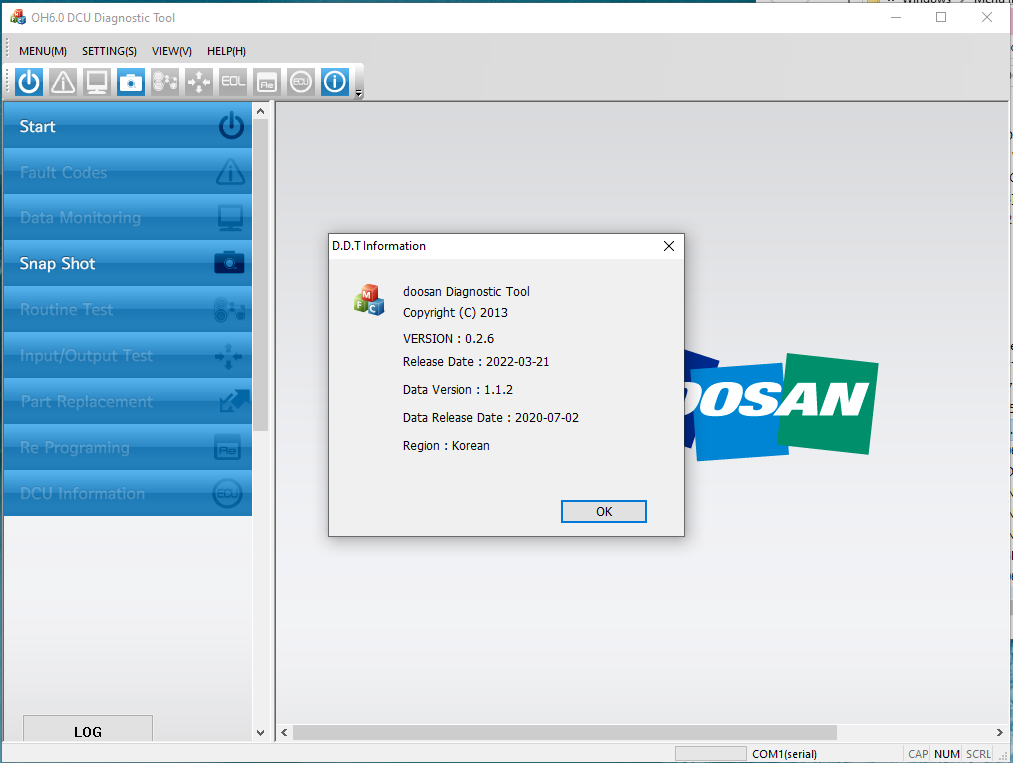

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

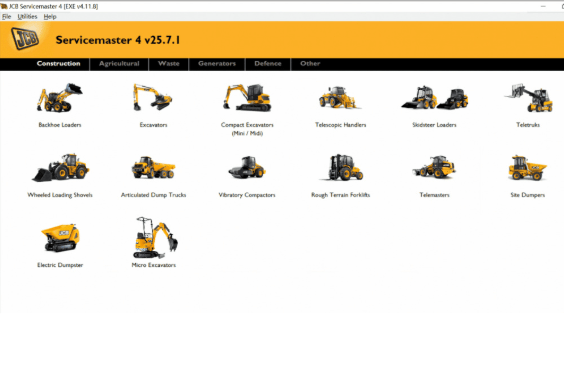

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

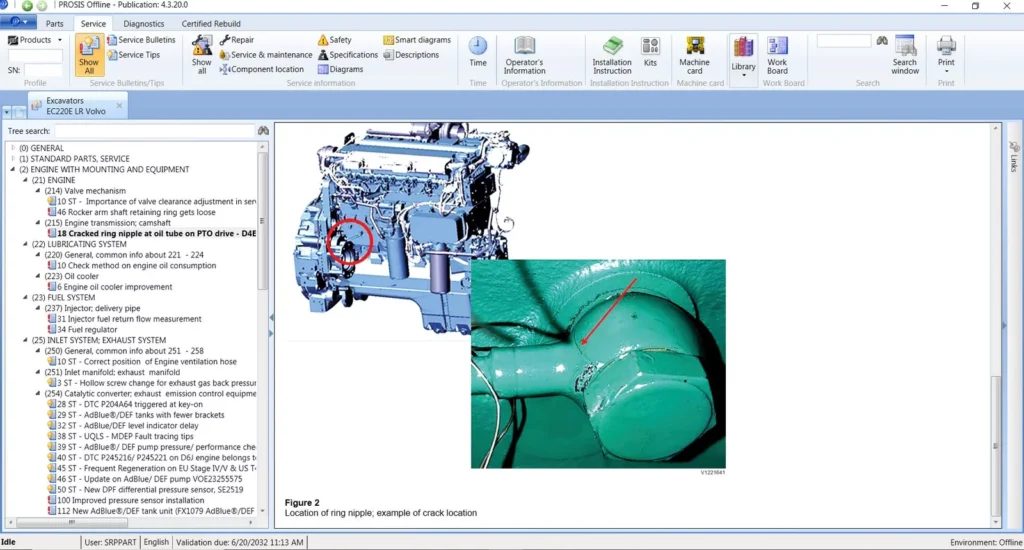

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.