Verify the electronic control module (ECM) calibration is correct. Check the calibration revision history found on QuickServe™ Online for applicable fixes to the calibration stored in the ECM. If necessary, calibrate the ECM again. Refer to Procedure 019-032 in Section 19.

Before performing troubleshooting work, verify the vehicle’s system voltage by monitoring battery voltage in the INSITE™ electronic service tool data monitor or connecting a digital volt ohm meter to the batteries. This will help identify a potential system voltage issue. Refer to the OEM service manual for specified voltage range and troubleshooting procedures.

If the engine will not start and Fault Code 559 comes active during cranking, but no speed sensor fault codes exist, monitor rail pressure with INSITE™ electronic service tool. The procedures referred to in this troubleshooting tree will also have checks for engine no start conditions.

Before servicing any fuel system components, (such as fuel lines, fuel pump, injectors, etc.) which would expose the fuel system or internal engine component to potential contaminants prior to disassembly, clean the fittings, mounting hardware, and the area around the component to be removed. Dirt or contaminants can be introduced into the fuel system and engine if the surrounding areas are not cleaned, resulting in damage to the fuel system and engine.

If fuel pressure is low, check the following:

1)Fuel system prime (make sure that there is fuel in the tanks and that the system is primed)

2)Fuel gear pump pressure.

If fuel gear pump pressure is correct, test for system leakage:

1)High pressure pump leakage

2)Injector leakage

3)Fuel rail pressure relief valve leakage.

If Fault Code 559 is inactive and there are no existing performance complaints, it is possible that the vehicle was run out of fuel or that the fault came active if the engine was not primed following fuel filter replacement. Clear the inactive fault code.

Fault Code 559 sets when the engine is running and measured rail fuel pressure remains at least 100 Bar [1450 psi] less than commanded pressure. Once detected, Fault Code 559 will remain active until the engine is turned off or until the measured rail fuel pressure matches the commanded rail fuel pressure. When a condition exists that causes Fault Code 559 to become active, it is typical for the fault code to become active when the engine is heavily loaded and become inactive when the engine is lightly loaded.

When Fault Code 559 occurs, the fuel system has lost its ability to maintain rail fuel pressure. Causes of this fault include:

1)Fuel inlet restrictions

2)Fuel filter plugging

3)Fuel gear pump output low

4)Fuel gear pump pressure regulator sticking or leaking

5)High pressure pump capacity decay (high leakage to drain from the high pressure pump)

6)Fuel rail pressure relief valve leaks to drain

7)Fuel rail pressure relief valve opens at too low a pressure

8)Injector fuel circuit leaks to drain

9)Pressure sensor reads more than 100 bar lower than actual pressure

10)Air in the fuel.

A few bubbles exiting the line during the test is expected. A foamy appearance is an indication of a leak that allows air to enter, a severe inlet restriction that causes cavitation, or a system that is not yet primed. If fuel inlet restriction is not excessive, the source of air entry could be isolated to one of the following: suction fuel lines, OEM fuel lines, suction-side fuel filter assemblies, or stand-pipe(s) in the fuel tank(s).

The fuel rail pressure sensor can be checked. When checking the fuel rail pressure sensor accuracy, make sure the high-pressure fuel rail is not pressurized. The fuel pump, high-pressure fuel lines, and fuel rail contain very high-pressure fuel. Do not loosen any fittings while the engine is running. Wait at least 10 minutes after shutting down the engine before loosening any fittings in the high-pressure fuel system, to allow the pressure to decrease to a lower level. There could be a significant amount of time waiting on the rail to depressurize completely to 0. It could be necessary to manually relieve the pressure from the high pressure fuel rail.

Intermittent ECM power supply connections can cause Fault Code 559. If the engine is running with an active Fault Code 559 and Fault Codes 449, 1911, or 2311 are not present, check the ECM power supply for intermittent connections or battery issues. Fault Code 1117 can also be active if this fault condition exits.

Inactive Fault Code/Exhausted Troubleshooting Tree:

Troubleshooting inactive Fault Code 559 can be very difficult. The fault code must be active for any of the outlined procedures in which the engine is operated during the test. For engines with high counts of inactive Fault Code 559 or if the troubleshooting tree has been exhausted, operate the engine on a chassis dynamometer or a diagnostic road test to duplicate the fault code. The most common causes of intermittent Fault Code 559 that are difficult to create are leaking high-pressure connectors that only leak when the engine and the fuel are hot, intermittent fuel supply restrictions such as debris floating in the fuel tank, and a fuel pressure relief valve that opens prematurely. Check the High Pressure Connector (HPC) and connector torque and torque to specification if necessary. Operate the engine on a chassis dynamometer or conduct a diagnostic road test to duplicate the fault code. Use INSITE™ electronic service tool to log fuel system parameters during testing.

Possible repairs:

1)Add fuel to the fuel tank or perform repairs to the vehicle’s tank or fuel gauge.

2)Repair the fuel leak.

3)Make sure the fuel pump pressure into the filter is within specification.

4)If the pump is OK, replace the fuel filter and prime the fuel system.

5)If the fuel inlet restriction is too high, check the OEM fuel lines from the tank for proper size. Make certain there are no kinks or bends in the fuel lines and the fuel lines are not clogged.

6)Replace the fuel pump.

7)If no issues are found, replace the suction side fuel filter and prime the fuel system.

8)Replace the injector of the cylinder that is contributing to the high return flow.

9)Replace the high-pressure fuel pump.

10)Replace the rail fuel pressure relief valve.

11)Repair the tampering

12)Check drain line restriction.

13)After replacing the fuel pump actuator, measure the fuel pump flow again. If the flow is not within specification, replace the high-pressure fuel pump.

14)Replace the ECM.

AGCO

AGCO ALLISON

ALLISON BENDIX

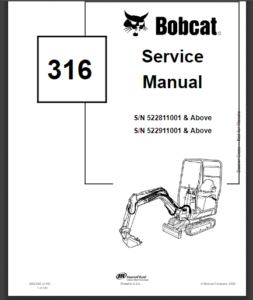

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

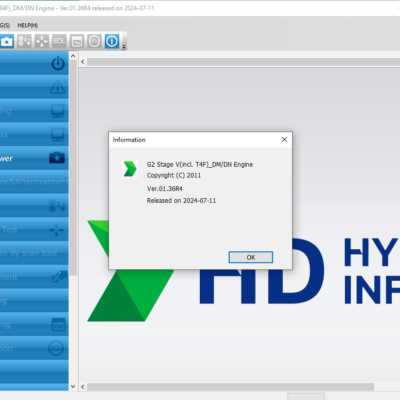

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPRO

JPRO MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

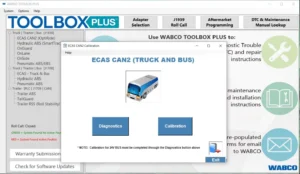

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

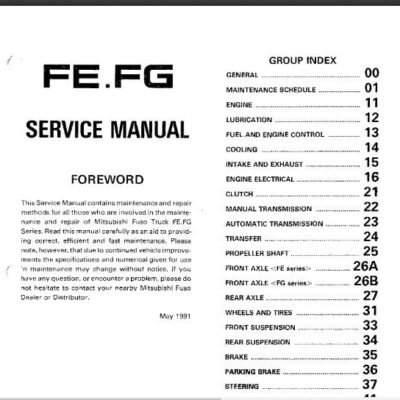

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.