HYSTER PC SERVICE TOOL 5 3 2024: Your Essential Maintenance Solution

The HYSTER PC SERVICE TOOL V5.3 is an essential resource for technicians working with Hyster and Yale trucks. It aids in maintenance and diagnostics, ensuring optimal performance and operational reliability. This article explores common user queries, troubleshooting options, and future updates. It also covers how to maximize the tool’s effectiveness and important security compliance aspects.

Common User Queries

Users of the HYSTER PC SERVICE TOOL V5.3 often have similar questions as they navigate the functionalities and capabilities of the software. Understanding these queries facilitates a smoother experience for technicians and enhances the overall utility of the tool.

Some of the most frequently asked questions include:

- What are the system requirements for the HYSTER PC SERVICE TOOL? It is important to ensure that the computer used meets the necessary specifications for optimal performance. These requirements typically include a compatible operating system, sufficient RAM, and adequate storage space.

- How do I install the software? Installation is straightforward. Users should follow the provided guidelines carefully, ensuring each step is completed to avoid complications during setup.

- Can I use the tool on multiple devices? Depending on the licensing agreement, the tool may be used on various machines, but it is essential to confirm terms of use to ensure compliance.

- What types of issues can the tool diagnose? The software is designed to address a wide variety of mechanical and operational issues, helping to identify problems quickly and accurately.

- Is there a user manual available? A comprehensive user manual is often provided with the software. This document serves as a valuable resource for troubleshooting and understanding features.

Additional queries often revolve around troubleshooting specific errors encountered while using the software. For example, users may ask how to interpret error codes or what steps to take when software updates are unsuccessful. Such inquiries are common as technicians seek to maximize efficiency in their work.

As the tools evolve, new questions may emerge, particularly regarding updates and enhancements. Staying informed about the latest changes can help users adapt and make the most of the HYSTER PC SERVICE TOOL V5.3, ensuring they remain efficient and informed.

Troubleshooting and Support

The performance of forklifts can be impacted by various issues, necessitating a reliable troubleshooting process. For users utilizing the HYSTER PC SERVICE TOOL, having a structured approach to diagnosing problems is essential. Common issues may include software glitches, communication errors, or equipment malfunctions, all of which can disrupt operations.

- Software Glitches: Users may encounter unexpected software behavior. Restarting the tool often resolves minor glitches. If issues persist, reinstalling the software may be advisable.

- Communication Errors: Connection issues between the tool and the truck can lead to data transfer errors. Ensuring that all cables are properly connected and checking for damaged ports can remedy this situation.

- Equipment Malfunctions: When the tool indicates a fault, consulting the diagnostic codes provided can help identify underlying issues. Regular maintenance checks are crucial to prevent equipment breakdowns.

Support resources are available for users who need assistance beyond basic troubleshooting. Hyster offers comprehensive documentation, including user manuals and troubleshooting guides, which can provide detailed insights into specific problems. Utilizing these resources can often lead to quick resolutions.

In cases where the problem cannot be resolved through self-diagnosis, reaching out to professional support teams is recommended. Hyster provides technical support that can guide users through complex repairs or software-related issues. It’s advisable to have the truck’s serial number and any relevant diagnostic codes ready when seeking assistance. This information can streamline the support process and lead to faster resolutions.

Regular training sessions are also beneficial for technicians. Staying updated on the latest software features and troubleshooting techniques can enhance their ability to address issues efficiently. Ensuring that all users of the tool have adequate training will minimize downtime and improve the overall functionality of the fleet.

Future Updates and Developments

The HYSTER PC SERVICE TOOL V5.3 is continuously evolving to meet the demands of modern operational environments. Regular updates are essential to enhance functionality, streamline processes, and incorporate user feedback.

Upcoming features and improvements expected in future releases include:

- Enhanced Diagnostic Capabilities: Utilization of advanced algorithms to provide more accurate diagnostics and quicker fault identification.

- User Interface Upgrades: An intuitive design overhaul aimed at improving user experience, making navigation simpler and more efficient.

- Mobile Compatibility: Adaptations for mobile devices to allow technicians to access the tool on-site without being tethered to a computer.

- Integration with IoT: Leveraging Internet of Things technology for real-time monitoring, enabling predictive maintenance solutions.

- Expanded Database Support: Inclusion of newer models and systems to ensure comprehensive coverage and support for the latest Hyster and Yale trucks.

Development teams actively monitor industry trends to ensure that the tool remains ahead of the curve. Collaboration with technicians who use the tool in the field provides essential insights into needed enhancements. Through beta testing phases, users can provide real-time feedback that significantly influences the direction of future updates.

Moreover, regular patches and updates will focus on reinforcing security measures. As operational software, maintaining compliance with industry standards and safeguarding sensitive information is paramount. Future rollouts will include upgraded security features designed to protect against emerging threats while ensuring smooth functionality.

Continuous improvement and adaptation ensure that the HYSTER PC SERVICE TOOL V5.3 remains a vital resource for technicians and service providers. By anticipating needs and implementing timely updates, Hyster reaffirms its commitment to delivering superior maintenance solutions.

Maximizing the Use of HYSTER PC SERVICE TOOL

To fully leverage the capabilities of the HYSTER PC SERVICE TOOL, familiarity with its interface and features is crucial. Technicians can enhance their efficiency and improve diagnostic accuracy by taking the time to understand the software’s functions. Comprehensive training sessions and consistent practice can significantly impact performance on the field.

Key strategies to maximize the use of this tool include the following:

- Regularly updating the software to access the latest features and improvements.

- Utilizing the built-in diagnostic functionalities to preemptively identify potential issues.

- Creating custom reports that can provide insights into equipment performance over time.

- Integrating the tool with existing systems for a seamless workflow.

Incorporating feedback from team members can also lead to enhanced usage strategies. Understanding real-world applications and sharing tips can foster a learning environment that encourages skill development.

Furthermore, staying abreast of new functionalities and updates provided by HYSTER will ensure that the tool remains effective and relevant. Engaging with user communities and forums can offer additional insights into best practices and innovative uses that may not be immediately apparent during routine operations.

Lastly, it’s important to maintain a disciplined approach to using the HYSTER PC SERVICE TOOL. Consistent usage, along with periodic reviews of past diagnostics, can lead to better forecasting and quicker resolutions when problems arise. By prioritizing an organized methodology and ongoing education, technicians can significantly enhance their proficiency with this indispensable service tool.

Frequently Asked Questions

The HYSTER PC SERVICE TOOL V5.3 is widely used, leading to a range of questions from users seeking clarity on its functionalities. Here are some of the most common inquiries:

- What systems does the HYSTER PC SERVICE TOOL support?

This tool is compatible with various Hyster and Yale truck models, allowing for efficient diagnostics and maintenance on a wide array of equipment. - How do I install the software?

Installation is straightforward. Users should download the software from the official Hyster website and follow the installation wizard prompts. - Is technical support available?

Yes, technical support is available through Hyster customer service. Users can access assistance for installation issues, troubleshooting, and general inquiries. - Can I run the software on different operating systems?

The HYSTER PC SERVICE TOOL is primarily designed for Windows. It’s advisable to confirm compatibility with the specific version of Windows before installation. - What kind of updates can I expect?

Regular updates are released to enhance functionality and address any bugs. Users are encouraged to check for updates periodically through the software interface. - Is there a fee associated with updates?

Most updates are provided at no additional charge, ensuring users can access the latest features and bug fixes without extra costs.

This FAQ section addresses common concerns that users may encounter. Staying informed about the capabilities and support options can significantly improve the overall experience with the HYSTER PC SERVICE TOOL.

Installation Services via TeamViewer

Installation of the HYSTER PC SERVICE TOOL 5.3 can be efficiently managed with the help of remote assistance tools like TeamViewer. This method allows technicians to guide users through the installation steps without the need for physical presence.

The process generally involves the following steps:

- Initiating a remote session between the technician and the user’s computer.

- Downloading the software directly from a trusted source, such as ecmtrucks.com.

- Executing the setup and following prompts for installation, ensuring that all necessary parameters are configured correctly.

- Activating the software license, which can also be assisted remotely if needed.

This installation approach enhances accuracy and minimizes the potential for errors, significantly streamlining the deployment of the software in operational settings. The convenience offered by TeamViewer makes it an appealing option for those unfamiliar with the technical aspects of software installation.

AGCO

AGCO ALLISON

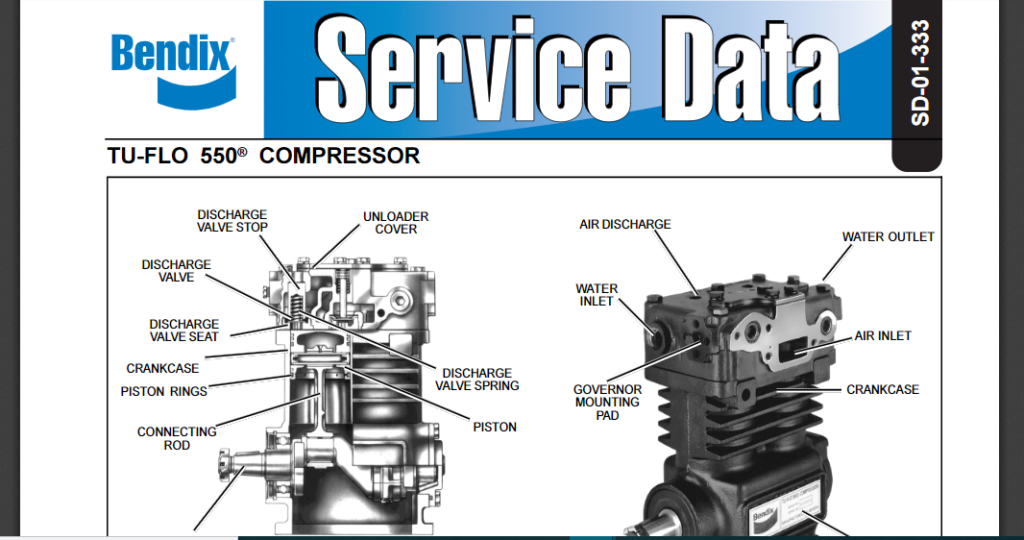

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.