DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R6 [2024.04]: Ultimate Guide for Efficient Marine Maintenance

The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer is a specialized device for diagnosing marine engines. It is essential for maintaining efficiency and performance in various marine applications. This tool provides comprehensive diagnostics, including error code reading and real-time monitoring. The DX22 helps technicians optimize engine performance and streamline maintenance processes in the marine industry.

Understanding the Doosan Diagnostic Tool DX22

The Doosan Diagnostic Tool DX22 plays a crucial role in modern marine engine diagnostics, enabling comprehensive insights into system performance and issues. This section delves into its purpose, significance, and the company behind it.

Purpose of the DX22

The primary aim of the Doosan Diagnostic Tool DX22 is to facilitate the efficient diagnosis of marine engines. It is designed to aid maintenance professionals by providing real-time data and diagnostic capabilities that enhance service quality and operational effectiveness.

Specifically, the DX22 serves the following purposes:

- Enhances troubleshooting processes by identifying engine faults quickly.

- Allows for timely maintenance, preventing costly breakdowns.

- Enables engine performance optimization which leads to improved fuel efficiency.

Importance in Marine Diagnostics

In the marine industry, where operational reliability is paramount, the importance of effective diagnostic tools cannot be overstated. The DX22 stands out due to its ability to analyze electronic control units (ECUs) in marine engines, thus improving diagnostic accuracy.

Key points regarding its importance include:

- Supports proactive maintenance strategies, reducing downtime and repair costs.

- Facilitates compliance with increasing regulatory requirements regarding emissions.

- Empowers technicians with the tools needed for efficient troubleshooting and repair.

Doosan Infracore Overview

Doosan Infracore is a leader in the manufacturing of heavy machinery and equipment, known for its commitment to innovation and quality. Established as a reputable entity within the global market, the company provides cutting-edge solutions across various sectors, including marine applications.

Some highlights of Doosan Infracore include:

- Extensive experience in engine and machinery design.

- Focus on sustainability and reducing environmental impact through advanced technologies.

- Robust support and service networks ensuring customer satisfaction.

Through its dedication to innovation, Doosan Infracore continues to enhance its offerings, particularly with diagnostic tools like the DX22, ensuring that end-users benefit from the latest advancements in marine technology.

Key Features

The Doosan Diagnostic Tool DX22 offers a range of exceptional features that enhance its functionality for marine diagnostics. Each feature contributes to improving accuracy, efficiency, and ease of use in diagnosing and maintaining marine engines.

Comprehensive Diagnostics

This tool is designed to deliver extensive diagnostic capabilities that cover various components of marine engines. By providing in-depth analysis, it helps technicians identify potential issues that may arise during operation. The comprehensive diagnostics include:

- Assessment of electronic control units (ECUs)

- Detailed fault codes and descriptions

- Analysis of system performance metrics

Such capabilities ensure that potential problems can be addressed proactively, reducing the likelihood of unexpected failures on the water.

Error Code Reading and Clearing

One of the standout features of the DX22 is its ability to read and clear error codes efficiently. Technicians can:

- Quickly retrieve current and historical error codes

- Interpret the codes to understand specific issues affecting performance

- Reset codes after resolving problems, allowing for immediate validation of repairs

This functionality streamlines the diagnostic process and ensures that issues are resolved in a timely manner.

Real-Time Monitoring

The capacity for real-time monitoring significantly enhances the diagnostic process. This feature allows for:

- Live data streaming: Continuous assessment of engine parameters while in operation.

- Visualization of performance data: Graphical display of metrics such as RPM, temperature, and pressure.

- Dynamic alerts: Notifications when specific thresholds are breached or anomalies occur.

Real-time monitoring ensures that technicians have immediate access to important performance information, enabling them to make informed decisions swiftly.

Programming Capabilities

The DX22 tool also incorporates programming functionalities that allow technicians to optimize engine performance. Key programming features include:

- Adjusting engine parameters for enhanced performance under specific conditions

- Customizing settings to meet operational requirements

- Updating ECU firmware to improve reliability and compliance with the latest standards

This flexibility supports not only improved performance but also better fuel efficiency, which is crucial in marine operations.

Intuitive Interface

The user-friendly design of the DX22 ensures that even technicians with limited experience can navigate the tool effectively. Characteristics of the intuitive interface include:

- A clean layout that simplifies access to various functions

- Visual aids such as charts and graphs that facilitate understanding of data

- Easily accessible help features for user guidance

This intuitive design enhances the overall user experience, promoting efficiency in diagnostics and reducing the learning curve for new users.

Technical Specifications

The technical specifications of the Doosan Diagnostic Tool DX22 highlight its capabilities and requirements, ensuring optimal performance and compatibility with various marine applications. Understanding these specifications is essential for effective utilization in the marine diagnostic process.

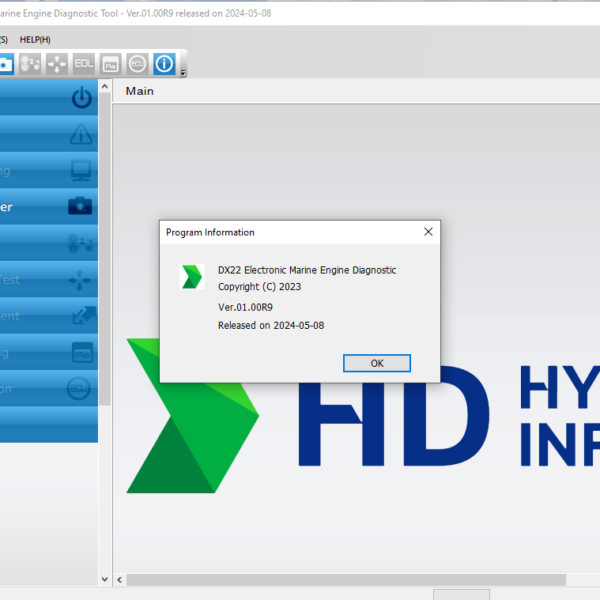

Version: 01.00R6 [2024.04]

The DX22 is equipped with version 01.00R6 [2024.04], representing the latest iteration designed to support advanced diagnostic functions specific to marine engines. This version includes enhancements compared to previous releases, ensuring improved reliability and efficiency during engine diagnostics.

Database Version: 2024.04

With a database version of 2024.04, the software offers updated information, including diagnostic trouble codes and repair procedures pertinent to modern marine engines. The updated database ensures that users have access to the most current data, enabling precise diagnostics and troubleshooting tasks.

File Size and Installation Requirements

The Doosan Diagnostic Tool DX22 has specific file size requirements for installation which are essential for efficient operation. The details are as follows:

- File Size: 65.1 MB

- Installed Size: 237 MB

Ample storage space must be available on the selected device for a smooth installation process. It is advisable to check system requirements before proceeding.

Operating System Compatibility

The software is designed to operate on modern Windows systems, ensuring wide accessibility for users. Compatibility details include:

- Windows 10 (64 bits)

- Windows 11 (64 bits)

This compatibility allows for seamless integration with contemporary computing environments, facilitating the installation and ongoing use of the tool.

Software License Type

The DX22 utilizes an unlimited license type, allowing unrestricted access to all features and functionalities throughout the ownership period. This licensing model provides significant value for marine technicians by minimizing barriers to software use during various diagnostic tasks.

Language Support

Effective language support is critical for ensuring usability and accessibility in diagnostic tools. The Doosan Diagnostic Tool DX22 accommodates users through its multilingual capabilities, enabling efficient operation across diverse linguistic backgrounds.

Database Language: Korean

The primary language of the database for the Doosan Diagnostic Tool DX22 is Korean. This ensures that the essential technical documentation, diagnostic parameters, and engine data are accurately represented for Korean-speaking technicians. The content is curated to meet the specific needs of operators who are familiar with the Korean language, contributing to accurate service and maintenance procedures.

Interface Languages: English and Korean

The user interface of the DX22 offers support in both English and Korean. This dual language capability enhances the accessibility of the tool for a broader audience, allowing technicians comfortable in either language to navigate the software effectively. The inclusion of both languages ensures that all users can take full advantage of the tool’s features without language barriers impacting their diagnostic capabilities.

- The English interface caters to a global audience, making it easier for non-Korean speakers to utilize the software.

- Korean support in the interface aligns with the database language, providing a seamless user experience for native speakers.

This multilingual approach is designed to facilitate effective communication of technical information, enhancing the overall efficiency of maintenance operations. The tool’s design reflects a commitment to meeting the diverse needs of users in the marine industry.

Engine and Vehicle Compatibility

The compatibility of the Doosan Diagnostic Tool DX22 with various marine engines and vehicles is a crucial aspect. Its ability to work with different models ensures that technicians can rely on it for diverse applications in the marine industry.

Supported Marine Engines

The DX22 is designed to support a wide range of Doosan marine engines. This includes engines utilized in commercial shipping, fishing vessels, and recreational boats. The compatibility extends to both older and newly launched models, ensuring comprehensive diagnostic coverage across the fleet.

- Doosan diesel engines for cargo vessels

- Doosan engines used in commercial fishing boats

- Marine engines for tugboats and barges

- Performance engines in recreational marine products

Industrial Equipment Compatibility

This diagnostic tool is not limited to marine applications; it also supports various types of industrial equipment that utilize Doosan engines. This versatility makes it an essential tool for technicians involved in both marine and industrial sectors.

- Engines in construction equipment

- Power units for generators

- Engines installed in specialized service vessels

- Engines for heavy-duty machinery

Latest Models and Technology Integration

The DX22 is continually updated to be compatible with the latest engine models and integrates the most advanced technologies in marine diagnostics. Technicians can expect support for the most recent releases, ensuring that they can handle any emerging challenges in the field.

- New generation Doosan engines featuring advanced fuel injection systems

- Integration with digital monitoring systems for enhanced performance tracking

- Support for engines equipped with eco-friendly technologies meeting current emission standards

Installation Guide

The installation process for the Doosan Diagnostic Tool DX22 is straightforward, ensuring that users can quickly set up their systems to begin utilizing this essential diagnostic tool. Proper installation is crucial for optimal functionality and performance.

System Requirements

To effectively run the Doosan Diagnostic Tool DX22, certain system requirements must be met. These requirements include:

- Operating System: Windows 10 (64-bit) or Windows 11 (64-bit)

- Available Disk Space: Minimum 300 MB for optimal installation.

- RAM: At least 4 GB of RAM is recommended.

- Processor: A minimum of 2 GHz dual-core processor is required.

- Network: Internet access is needed for updates and remote support.

Step-by-Step Installation Process

The installation process involves several key steps to ensure successful setup. Follow these instructions carefully to install the software.

Downloading the Software

The first step is to download the diagnostic tool software. This can usually be done from the official Doosan Infracore website or through authorized distributors. Ensure that the download is for the latest version (01.00 R6 with database version 2024.04).

Installing Drivers

After downloading the software, the next step involves installing the necessary drivers for the tool:

- Locate the downloaded driver files.

- Run the installation program for the drivers.

- Follow the on-screen instructions to complete the installation.

- Restart your computer if prompted to do so.

Initial Setup and Configuration

Once the drivers are installed, proceed with the initial setup of the software:

- Run the Doosan Diagnostic Tool DX22 application.

- Follow the configuration wizard to set parameters specific to your equipment and user preferences.

- Verify that the software recognizes the connected ECU.

- Complete any additional configuration as prompted by the software.

Remote Installation Support via TeamViewer

For users who may encounter difficulties during the installation process, remote support is available through TeamViewer. This allows a qualified technician to assist directly:

- Ensure TeamViewer is installed on your PC.

- Initiate a support session by providing the generated ID and password to the technician.

- The technician will assist you in completing the installation and troubleshooting any issues in real-time.

Benefits of Using the DX22

The Doosan Diagnostic Tool DX22 provides a range of benefits that enhance diagnostics, improve engine performance, and streamline training within the marine industry.

Diagnostic Efficiency

Utilizing the DX22 significantly enhances diagnostic efficiency for marine engines and machinery. Its comprehensive diagnostic capabilities enable technicians to identify issues swiftly, ensuring minimal downtime for vessels.

Key aspects include:

- Rapid error code analysis, reducing the time taken to troubleshoot problems.

- Comprehensive reporting features that highlight multiple potential issues in one go.

- Support for real-time monitoring, allowing immediate action before minor issues escalate into serious failures.

Engine Performance Optimization

Engine performance is crucial for operational efficacy in the marine industry. The DX22 provides various tools designed to optimize engine functionality.

- Allows programming capabilities that adjust engine parameters to suit specific operational conditions.

- Facilitates monitoring of engine performance metrics, helping to ensure optimal fuel efficiency.

- Identifies opportunities for enhancements in propulsion systems used in different marine applications.

Cost Reduction

The financial implications of using the DX22 are significant, particularly in reducing maintenance and operational costs.

- Streamlined diagnostics lower repair time, which translates to reduced labor costs.

- Enhanced engine performance leads to fuel savings, a critical factor in the marine industry.

- Preventive maintenance capabilities help avoid costly breakdowns and emergency repairs.

Training and Education

The intuitive design of the DX22 serves as a valuable educational tool for new technicians, creating a seamless learning environment. This is particularly vital in an industry that requires specialized knowledge for effective operation and maintenance of marine engines.

- The user-friendly interface simplifies navigation, making it accessible for those with varying levels of experience.

- Interactive diagnostic functions allow users to learn through practical application.

- Resources and support materials aid in developing a deeper understanding of marine engine systems.

Comparisons with Other Diagnostic Tools

When it comes to diagnosing marine engines, having the right tool is crucial. There are several competing diagnostic tools available on the market, each with its strengths and weaknesses.

Cummins Insite

Cummins Insite is a well-known diagnostic software primarily aimed at Cummins engines. Its robust features cater to engine performance analysis and troubleshooting. However, it lacks compatibility with marine-specific engines outside the Cummins brand. This means marine technicians relying on diverse engine types may find it limiting.

- Strengths: Offers detailed engine data and error troubleshooting specifically for Cummins engines.

- Weaknesses: Limited to Cummins products, making it less versatile for marine applications.

Eaton Fuller Advantage

Eaton Fuller Advantage focuses on transmission diagnostics for heavy-duty vehicles. While effective in its domain, it does not cover the nuances of marine engine diagnostics. This tool is tailored more towards land-based applications, leaving a gap for marine professionals who need a comprehensive solution for engine management.

- Strengths: Excellent for transmission-related repairs and diagnostics in trucks and heavy machinery.

- Weaknesses: Lacks functionality for marine engines and their specific requirements.

Volvo Vocom

Volvo Vocom is designed for Volvo engines and vehicles. While it provides advanced diagnostic capabilities, the focus is primarily on Volvo products. This specificity can be a drawback for marine technicians who often work with a variety of engine brands and models.

- Strengths: Comprehensive diagnostics for Volvo engines, providing in-depth performance data.

- Weaknesses: Limited to Volvo-related diagnostics; not suitable for mixed fleets commonly found in marine operations.

Unique Advantages of the DX22

The Doosan Diagnostic Tool DX22 stands apart from competing diagnostic tools through its dedicated focus on marine engines and systems. Its tailored functionalities ensure that marine professionals can diagnose and troubleshoot issues effectively.

- Comprehensive Marine Focus: Specifically designed for a wide range of Doosan marine engines, making it versatile for various applications.

- Intuitive User Interface: Simplifies navigation for technicians, enhancing efficiency during diagnostics.

- Real-Time Monitoring: Allows technicians to track engine performance dynamically, facilitating quicker response to issues.

- Cost Efficiency: Reduces downtime and repairs through effective diagnostics, directly impacting operational costs for marine fleets.

Performance Optimization

Performance optimization is a crucial aspect in the maintenance and operation of marine engines. By focusing on the fine-tuning of parameters, fuel consumption, and overall engine performance, vessel operators can achieve greater efficiency and reliability.

Parameter Adjustments

One of the primary ways to enhance engine efficiency is through parameter adjustments. This process involves modifying various settings within the engine control unit (ECU) to optimize performance according to operational needs. The Doosan Diagnostic Tool DX22 provides several parameters that can be fine-tuned, such as:

- Engine timing settings

- Fuel injection rates

- Boost pressure levels

- Temperature limits

By adjusting these parameters, technicians can ensure that marine engines operate at their peak efficiency, resulting in improved power and fuel efficiency. Regularly reviewing and adjusting these settings is vital, especially as environmental conditions and load requirements change.

Fuel Consumption Savings

Fuel efficiency is a key factor in the operational cost of marine operations. The ability to effectively manage and reduce fuel consumption has direct implications on a vessel’s bottom line. The DX22 facilitates the monitoring and analysis of fuel consumption metrics through real-time diagnostics. Techniques for achieving fuel savings include:

- Optimizing engine load and speed to maintain efficiency

- Adjusting fuel-to-air ratios to enhance combustion efficiency

- Regular maintenance checks to ensure all components function correctly

Implementing these strategies can lead to significant reductions in fuel costs, making operations more sustainable and profitable. The emphasis on fuel savings is particularly important in an era of tightening regulations and rising fuel prices.

Enhancing Marine Engine Performance

Improving marine engine performance not only boosts efficiency but also prolongs the lifespan of the equipment. The DX22 plays a pivotal role in performance enhancement by providing valuable insights into engine operation. Key strategies for enhancing engine performance include:

- Conducting routine diagnostics to identify and rectify any underlying issues

- Implementing performance tuning protocols based on data gathered from the ECU

- Ensuring the vessel operates within optimal parameters for varying sea conditions

Through proactive management and the use of the diagnostic capabilities of the DX22, operators can maintain stronger engine performance, which leads to smoother operations and better responsiveness during critical maneuvers.

Emissions testing and compliance are crucial in the marine industry, particularly as regulations become stricter to protect the environment. Understanding the applicable standards and how to maintain compliance is essential for operators and technicians.

Emissions Testing and Compliance

Tier Standards and Regulations

The marine industry is subject to various emissions standards that aim to control the amount of pollutants released into the environment. Tier standards are established by organizations such as the Environmental Protection Agency (EPA) in the United States and the International Maritime Organization (IMO) globally. These standards dictate the permissible levels of emissions based on the type of engine and the year of manufacture.

- Tier 1: Initially established to reduce emissions from marine engines; sets basic limits for NOx and particulate matter.

- Tier 2: Introduced stricter limits, requiring significant reductions in emissions for new engines.

- Tier 3: Further advances emissions control technology and mandates lower NOx emissions for marine engines operating in designated emission control areas (ECAs).

- Tier 4: Aimed at significantly reducing emissions, especially for newly manufactured or rebuilt engines, implementing advanced technologies and after-treatment systems.

Ensuring Compliance

To ensure compliance with emissions standards, marine operators must implement regular testing and maintenance protocols. This includes conducting emissions tests to measure the engine’s output against established tier limits. Frequent checks ensure that engines remain within the permissible range and function efficiently.

- Conduct regular emissions testing as part of routine maintenance.

- Utilize diagnostic tools to assess the engine’s performance and emissions output.

- Keep thorough records of all emissions tests and maintenance activities to demonstrate compliance.

- Stay updated on any changes to tier standards and regulatory requirements to adapt practices accordingly.

Emission Diagnostics with DX22

The Doosan Diagnostic Tool DX22 is equipped to facilitate emissions diagnostics effectively. This tool aids in identifying potential issues that may lead to non-compliance with emissions standards.

- Provides real-time data on emissions levels, allowing prompt identification of deviations.

- Enables technicians to read and clear error codes that may be indicative of emissions-related problems.

- Offers insights into engine performance, helping to optimize fuel efficiency and reduce emissions.

- Facilitates adjustments to engine parameters to align emissions output with regulatory demands.

Troubleshooting Common Issues

Troubleshooting is essential for maintaining the efficiency of the Doosan Diagnostic Tool DX22. This section outlines common issues users may encounter, offering insights into resolving them effectively.

Connectivity Problems

Connectivity issues can arise due to various factors when using diagnostic tools. Ensuring proper connections between the DX22 and the marine engine is critical. Here are some common connectivity problems and how to address them:

- Cable Connections: Inspect all cables and connectors for damage or wear. Ensure that they are firmly connected and not loose.

- Bluetooth Connectivity: If using Bluetooth, ensure the device is paired correctly with the ECU. Check for interference from other devices in the vicinity.

- Port Issues: Verify that the correct port settings are configured on the software. Sometimes, switching USB ports on the computer can resolve issues.

- Firewall Settings: Occasionally, firewalls or security settings on the computer can block the software. Ensure that the DX22 program is whitelisted.

Software Glitches

Software glitches hinder diagnostics and can result from various factors. Understanding these issues can facilitate a smoother experience. Common software glitches include:

- Application Crashes: Regularly update the software to the latest version to minimize crashes. If the application still crashes, reinstalling may be necessary.

- Loading Delays: Slow loading times can occur due to insufficient computer resources. Closing unnecessary programs can improve performance.

- Incompatibility Errors: Situations may arise where the software doesn’t respond as expected due to OS compatibility. Ensure that the system meets the software requirements.

- Error Messages: Frequent error messages indicate deeper issues. Logging these errors can help with troubleshooting. Consult the user manual for specific error codes.

Error Code Interpretation

Interpreting error codes correctly is crucial for effective diagnostics. Each code signifies a particular issue that needs attention. Here’s how to approach error code interpretation:

- Refer to the Database: Use the integrated database in the DX22 for error code definitions. This can provide insights into potential malfunctions.

- Prioritize Issues: Not all error codes indicate critical problems. Some may require monitoring rather than immediate repairs. Categorize issues based on urgency.

- Follow the Diagnostic Steps: Each error code comes with recommended troubleshooting steps. Following these can help identify the root of the problem effectively.

- Documentation: Maintain a log of error codes and the resultant actions taken. This information can be valuable for future diagnostics and troubleshooting.

Software updates are crucial for maintaining the efficiency and accuracy of diagnostic tools in marine applications. Staying current with software versions ensures that users have access to the latest features and improvements.

Software Updates

Importance of Regular Updates

Regular software updates play a vital role in the functionality and reliability of the diagnostic tool. By updating the software, users benefit from:

- Enhanced performance and speed of the tool.

- Bug fixes and security patches that protect sensitive data.

- Access to new features that improve diagnostic capabilities.

- Compatibility with the latest models and technological advancements.

- Improved user experience through refined interface elements.

How to Update DX22

Updating the Doosan Diagnostic Tool DX22 is a straightforward process that can be completed in a few steps. The following guide outlines the procedure:

- Check for available updates by accessing the software’s update menu.

- Download the latest version from the designated source.

- Follow the on-screen instructions to install the updates.

- Restart the software to apply the changes and ensure all features are functioning correctly.

- Maintain a regular schedule for checking updates to stay up to date.

Latest Features in 2024.04 Release

The 2024.04 release of the DX22 introduces several innovative features designed to enhance user experience and diagnostic capabilities, including:

- Improved algorithm for error code interpretation, allowing for faster troubleshooting.

- Expanded database of marine engines for broader compatibility.

- New real-time monitoring tools that provide deeper insights into engine performance.

- Refined user interface for easier navigation and improved accessibility.

- Enhanced programming capabilities to optimize engine parameters more efficiently.

Support and resources are vital for users to maximize the efficiency and functionality of diagnostic tools. Access to technical assistance, online educational materials, and user communities contributes to a smoother experience.

Support and Resources

Technical Support Availability

Technical support is crucial for users to effectively resolve any issues encountered with the diagnostic tool. Doosan provides dedicated support services designed to help technicians troubleshoot and optimize the use of the DX22. The support team is available around the clock to handle inquiries and assist users with installation or operational challenges.

Support methods include:

- Live chat assistance for immediate queries.

- Email support for detailed inquiries and issues.

- Phone support during business hours for voice-driven assistance.

The continuity in support ensures that users can maintain productivity and minimize downtime associated with equipment diagnostics.

Online Resources and Tutorials

A wealth of online resources is available to enhance user knowledge and skill in operating the diagnostic tool. These resources often include step-by-step tutorials, instructional videos, and downloadable manuals that cover various aspects of the DX22. Users can benefit from comprehensive learning materials aimed at different experience levels.

Key online resources include:

- Video tutorials that visually guide users through the tool’s features and functions.

- User manuals that provide detailed explanations of installation, navigation, and troubleshooting procedures.

- FAQ sections addressing common concerns and questions.

Access to these resources supports users in leveraging the full potential of the diagnostic tool effectively.

User Community and Forums

Community engagement plays a significant role in user support. Participating in forums and discussion groups allows users to share experiences, solutions, and tips with one another. Engaging with peers fosters a collaborative environment where users can learn from one another’s insights.

The benefits of joining the community include:

- Opportunities to connect with other users and experts in marine diagnostics.

- Access to shared knowledge on troubleshooting and advanced usage.

- A platform for discussing updates, features, and best practices.

The user community serves as a valuable resource, enhancing the collective knowledge and experience among DX22 users.

Future Trends in Marine Diagnostics

The marine diagnostics sector is evolving rapidly, driven by advancements in technology and increasing demands for efficiency. As the industry embraces digital solutions, several key trends are shaping the future of marine diagnostics.

Digitalization in Marine Industry

The push towards digitalization is transforming traditional practices in the marine industry. Digital tools and systems are being integrated into nearly every aspect of marine operations. The adoption of cloud computing, IoT devices, and real-time data analytics is facilitating better decision-making and enhancing system performance. Companies are increasingly relying on digital platforms to monitor and manage equipment health, streamlining the diagnostic process.

- Cloud-based diagnostics enable remote monitoring, allowing technicians to troubleshoot and address issues without being physically present.

- IoT devices gather critical data from engines, aiding in predictive maintenance and reducing the likelihood of unexpected failures.

- Data analytics tools analyze trends over time, helping operators make informed decisions based on historical performance data.

Advancements in Diagnostic Technologies

Technological innovations are playing a critical role in enhancing the capabilities of diagnostic tools. Newer devices boast sophisticated algorithms that facilitate in-depth analysis of engine performance and diagnostics. These advancements make it easier to diagnose complex problems while improving the speed and accuracy of results.

- Artificial Intelligence (AI) is increasingly being integrated into diagnostic tools, providing machine learning capabilities that improve understanding of system behaviors over time.

- Advanced graphical user interfaces (GUIs) offer more intuitive navigation and visualization, leading to quicker diagnostics and reduced training time for technicians.

- Mobile applications are becoming more common, allowing real-time diagnostics and access to information from any location.

Impact on Operational Efficiency

As marine diagnostics become more advanced and integrated, operational efficiency is bound to improve significantly. The focus has shifted toward minimizing downtime and operational costs while maximizing performance and safety.

- Remote diagnostics reduce the need for on-site visits, saving time and resources for both technicians and marine operators.

- Enhanced diagnostics lead to quicker identification of issues, allowing for timely interventions and maintenance.

- Overall, these advances contribute to lower operational risks and improved compliance with environmental regulations.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR![The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer 01.00R5 [2024.03] is designed for optimal engine performance in marine applications. This tool offers advanced diagnostic capabilities and is compatible with a variety of marine engines. It plays a crucial role in maintaining and managing engine health. The latest version includes features that enhance connectivity and user experience, making it a valuable asset for marine operators and technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-ECU-ANALYZER-01.00R5-2024.03-600x600.png)

![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R6 [2024.04] The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer is a specialized device for diagnosing marine engines. It is essential for maintaining efficiency and performance in various marine applications. This tool provides comprehensive diagnostics, including error code reading and real-time monitoring. The DX22 helps technicians optimize engine performance and streamline maintenance processes in the marine industry.](https://ecmtrucks.com/wp-content/uploads/2024/08/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-ECU-ANALYZER-01.00R6-2024.04.png)

Reviews

Clear filtersThere are no reviews yet.