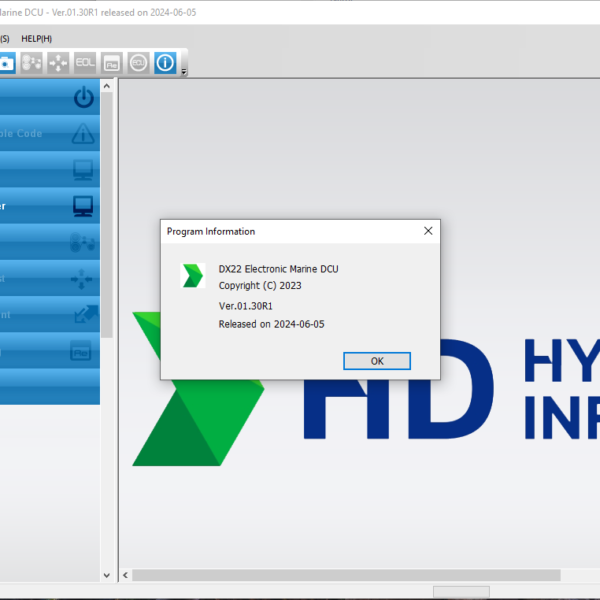

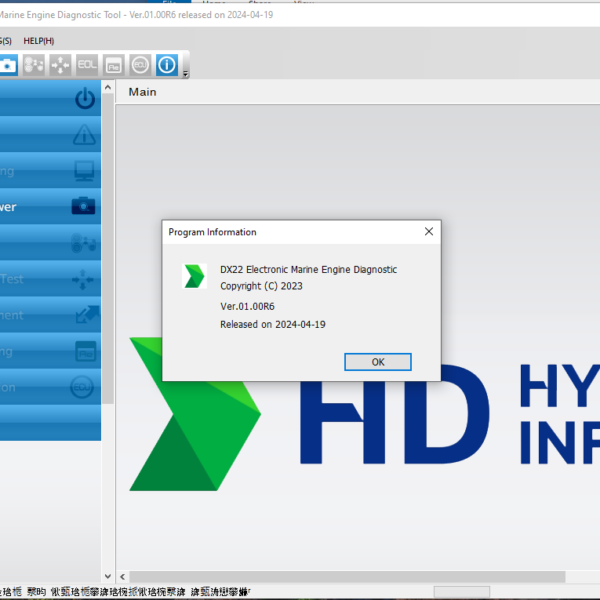

DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R5 [2024.03]: Boost Your Marine Engine Performance Today!

The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer 01.00R5 [2024.03] is designed for optimal engine performance in marine applications. This tool offers advanced diagnostic capabilities and is compatible with a variety of marine engines. It plays a crucial role in maintaining and managing engine health. The latest version includes features that enhance connectivity and user experience, making it a valuable asset for marine operators and technicians.

Overview of Doosan Diagnostic Tool DX22

The Doosan Diagnostic Tool DX22 is a cutting-edge solution designed to enhance the diagnostic capabilities of marine engines. With a focus on accuracy and efficiency, this tool plays a pivotal role in ensuring optimal performance in the marine industry.

Importance in the Marine Industry

The significance of the Doosan Diagnostic Tool DX22 in the marine sector cannot be overstated. As marine engines become more complex with advancements in technology, reliable diagnostic tools are essential for maintaining operational efficiency. Proper diagnostics help to:

- Ensure optimal engine performance and reliability.

- Reduce the risk of unexpected breakdowns.

- Facilitate timely maintenance, extending the service life of engines.

- Support compliance with regulatory standards, improving safety measures.

In an industry where downtime can lead to substantial financial losses, the DX22 offers valuable insights that empower technicians and operators to address issues promptly. This tool is integral for maintaining the health and performance of marine fleets.

Latest Version Highlights

The most recent iteration, the DX22 Electronic Marine ECU Analyzer 01.00R5 [2024.03], introduced in March 2024, incorporates several important enhancements that set it apart from previous models. Key highlights include:

- Improved Compatibility: Supports an even wider range of marine engine models and brands, allowing for streamlined diagnostics across different types of vessels.

- Enhanced Connectivity: Offers advanced integration options with various management systems, ensuring seamless data flow between devices.

- User-Centric Design: Features an intuitive graphical interface that simplifies navigation and eases data interpretation.

- Updated Diagnostic Capabilities: Provides real-time monitoring and analysis, enabling quick issue identification and resolution.

The focus on user experience and technological advancements ensures that the DX22 remains at the forefront of marine diagnostic solutions. These enhancements not only improve functionality but also increase ease of use for operators and technicians alike.

Key Features of the DX22

The Doosan Diagnostic Tool DX22 incorporates several advanced features that enhance its functionality and usability in the marine industry. These key characteristics contribute to improved diagnostic precision and allow for efficient management of marine engines.

Wide Compatibility

The compatibility of the DX22 with a range of marine engines is a significant advantage. This feature ensures that technicians can utilize the tool across various platforms without limitations.

Compatible Engine Models

- The DX22 is designed to work with numerous engine models, facilitating seamless diagnosis and maintenance. It supports non proprietary engines, allowing for broader application in operations.

- From smaller recreational vessels to larger commercial crafts, the tool covers an extensive variety of engine specifications.

Supported Brands

- This analyzer is compatible with leading marine engine manufacturers, ensuring that it meets the needs of a diverse customer base.

- Well-known brands recognized in the industry see support from the DX22, allowing for reliable diagnostics irrespective of the engine type.

Advanced Connectivity Options

The DX22 features sophisticated connectivity options that promote its integration into existing marine systems.

Integration with Management Systems

- The tool allows for seamless integration with various marine management systems, streamlining operational effectiveness.

- Data exchange between the DX22 and management systems occurs smoothly, helping to maintain real-time information on engine status.

Supported Diagnostic Devices

- Numerous diagnostic devices can work with the DX22. This compatibility ensures flexibility in diagnostic processes.

- Having multiple device support means the DX22 can adapt to different setups within marine frameworks.

User-Friendly Interface

The DX22 features a user-centric design that simplifies the diagnostic process. Its interface ensures that users can efficiently navigate through the tool’s capabilities.

Graphical Interface

- A clear and informative graphical interface provides users with critical information at a glance.

- This setup allows technicians to assess engine data with clarity, minimizing the complexity often associated with diagnostic operations.

Simplified Navigation

- Navigation throughout the tool is intuitive, enabling users to easily access various functions and features.

- Such an interface design minimizes training time for new users and maximizes operational efficiency.

Regular Software Updates

To maintain optimal performance and accuracy, the DX22 benefits from frequent software updates. These updates are crucial in providing users with the latest diagnostic features and enhancements.

Update Process

- Updates can be easily installed, ensuring that users can quickly access new capabilities without extensive downtime.

- The process is streamlined, allowing for minimal disruption during operational periods.

Benefits of Updates

- Regular updates ensure that the tool remains aligned with evolving marine engine technologies, maintaining its reliability and accuracy.

- Users benefit from enhancements that improve diagnostic capability and system performance over time.

Real-Time Diagnostic Capabilities

The DX22 excels in providing real-time diagnostic information, which is crucial for effective engine monitoring.

Live Data Monitoring

- This feature allows technicians to view engine performance data instantaneously, facilitating quick assessments during operations.

- Live monitoring supports proactive measures, ensuring issues can be addressed promptly, thus avoiding costly repairs.

Quick Troubleshooting

- The ability to troubleshoot in real-time enables immediate diagnosis of faults, making the tool invaluable during critical situations.

- Such speed in troubleshooting enhances overall operational reliability, significantly reducing unexpected downtimes.

Applications in Marine Operations

In the maritime industry, efficient and effective operations are paramount. The Doosan Diagnostic Tool DX22 plays an essential role in several applications that enhance marine operations.

Maintenance Scheduling

Proper maintenance is crucial for the longevity and efficiency of marine engines. The tool facilitates maintenance scheduling through precise diagnostic data, which helps operators determine when maintenance is necessary.

- Predictive diagnostics enable early identification of potential issues.

- Scheduled maintenance can be optimized to minimize downtime.

- Built-in alerts remind technicians about upcoming maintenance tasks.

- Historical data analysis guides maintenance intervals based on engine performance trends.

By utilizing this diagnostic tool, maintenance activities can be systematically planned, leading to improved operational reliability.

Fleet Management Optimization

Efficiency in managing a fleet of marine vessels can significantly affect a company’s bottom line. The DX22 assists in fleet management by providing real-time performance data for each engine involved.

- Operators can monitor the health of multiple engines simultaneously.

- Data-driven insights allow fleet managers to make informed decisions regarding engine repairs or replacements.

- Resource allocation can be enhanced based on the performance metrics of various vessels.

- Detailed reporting ensures that fleet operators comply with regulations and performance standards.

This level of oversight ensures that every vessel operates at optimal efficiency, directly influencing operational costs and service quality.

Training and Education Tool

Training personnel in the marine sector is crucial as technology evolves. The DX22 provides a robust platform for training technicians and operators.

- Realistic simulation features allow trainees to engage with the tool in a controlled environment.

- Hands-on experience ensures that technicians are better prepared for practical applications.

- Interactive learning modules are designed to familiarize users with diagnostic procedures and troubleshooting techniques.

- Certification processes can be established to validate technician proficiency.

This training tool not only enhances skills but also improves overall safety and efficiency within marine operations.

Benefits of Using Doosan Diagnostic Tool DX22

The advantages of utilizing the Doosan Diagnostic Tool DX22 extend far beyond mere diagnostics. Its ability to enhance operational efficiency and reduce costs play a pivotal role in modern marine engine management.

Efficiency in Engine Diagnostics

One of the standout benefits of the DX22 is its significant efficiency in engine diagnostics. This tool delivers precise and timely diagnostic information, allowing technicians to quickly identify issues before they escalate.

- This rapid diagnosis minimizes downtime, ensuring vessels remain operational and productive.

- The real-time monitoring capabilities provide continuous insights into engine performance, enabling proactive maintenance and avoiding unexpected failures.

- By streamlining the diagnostic process, the DX22 enhances the overall efficiency of marine operations, allowing for better allocation of resources.

Cost Savings on Repairs

Using the DX22 can lead to substantial cost savings in repair and maintenance activities. Early detection of potential problems allows for less extensive repairs, which translates to reduced labor and parts costs.

- Timely diagnostics prevent minor issues from evolving into major malfunctions, significantly decreasing the repair expenses.

- With the ability to perform diagnostics in-house, companies can lower reliance on external services and save on service fees.

- Moreover, optimized maintenance scheduling facilitated by this tool prolongs the lifespan of equipment, further lowering long-term costs.

Productivity Improvements

The DX22 directly contributes to increased productivity within marine operations. Its user-friendly interface allows operators to navigate quickly through diagnostics and data retrieval, reducing the time spent on troubleshooting.

- Efficient diagnostics enable crew members to return to normal operations faster, thereby improving overall productivity.

- As marine operators spend less time dealing with repairs, they can focus on other critical aspects of their operations, driving greater efficiency across the board.

- This added productivity not only benefits individual vessels but also enhances the capabilities of entire fleets.

Regulatory Compliance Assistance

Ensuring compliance with regulatory standards is an important aspect of marine operations. The DX22 aids companies in meeting environmental and safety regulations through its comprehensive diagnostic capabilities.

- The tool helps identify issues that may lead to non-compliance, allowing operators to address concerns before they result in fines or legal repercussions.

- Regular updates and maintenance checks facilitated by the DX22 ensure that all equipment meets current standards, safeguarding the company’s operations.

- With the right information and tools, organizations can navigate the complex regulatory landscape more effectively, ensuring sustained compliance.

Comparing DX22 with Other Diagnostic Tools

In the competitive landscape of marine diagnostic tools, a detailed comparison can highlight the unique advantages of the DX22 over its counterparts. This section evaluates its versatility, build quality, user-friendly operations, and ongoing support and updates.

Versatility of DX22

The DX22 stands out in terms of versatility, offering compatibility with a wide range of marine engines. This flexibility allows it to cater to different users, from small boat operators to larger marine fleets. Its ability to diagnose various brands and engine models means that operators do not need to invest in multiple diagnostic tools, streamlining their maintenance processes.

- Compatible with numerous engine types, enhancing its utility in diverse marine applications.

- Supports multiple brands, making it a universal solution for technicians.

Quality of Build

When it comes to durability, the DX22 is designed to withstand the rigors of marine environments. Its robust construction ensures that it can endure harsh conditions while maintaining performance reliability. This quality is vital for professionals who rely on consistent and dependable tools.

- Manufactured with high-quality materials that prevent wear and tear over time.

- Engineered to function seamlessly in high-pressure marine settings.

User-Friendly Operations

The DX22 excels in user experience, featuring an intuitive interface that simplifies navigation and data access. Technicians can quickly familiarize themselves with the system, reducing training time and enhancing productivity.

- Graphical interface designed for quick comprehension and effective interaction.

- Simplified navigation process allows for efficient usage, even for those new to diagnostic tools.

Continuous Support and Updates

A significant aspect of the DX22’s appeal lies in its commitment to support and updates. Regular software updates ensure users have access to the latest diagnostic technologies and features, crucial for keeping pace with advancements in engine technology.

- Regular updates enhance functionality and ensure compliance with evolving industry standards.

- Continuous support helps users resolve issues promptly, maintaining operational efficiency.

How DX22 Enhances Fleet Management

The DX22 is a vital tool for elevating fleet management practices, focusing on engine health, preventative maintenance, and minimizing downtime. Its advanced features streamline operations and help maintain efficiency across multiple vessels.

Tracking Engine Health

Effective fleet management hinges on the ability to monitor and assess each engine’s condition in real time. The DX22 provides comprehensive tracking solutions that enable fleet operators to maintain optimal usage of their resources. Key aspects include:

- Real-time performance monitoring, allowing operators to access crucial data regarding engine efficiency.

- Alerts for potential issues, ensuring proactive measures can be taken before problems escalate.

- Detailed reporting capabilities that support analysis of engine performance over time, helping to identify trends and recurring issues.

Preventative Maintenance Planning

A proactive approach to maintenance significantly reduces unexpected failures and extends the life of marine engines. The DX22 supports preventative maintenance by offering:

- Automated scheduling tools that remind operators of upcoming maintenance tasks based on the engine’s performance data and usage patterns.

- Maintenance history tracking, which allows teams to review past repairs and adjustments, enabling more informed decision-making.

- Guided maintenance procedures, simplifying the process for technicians and ensuring that tasks are performed correctly and efficiently.

Reducing Downtime

Minimizing downtime is critical for maximizing the operational capacity of a fleet. The DX22 enhances this aspect by facilitating faster diagnoses and solutions, which include:

- Quick diagnostic capabilities that identify issues instantly, minimizing the time vessels spend inoperable.

- Access to live data from engines, which allows for immediate analysis and troubleshooting during operation.

- Integrative support for remote diagnostics, which empowers technicians to assist on-site repairs without the need for travel, saving both time and costs.

Training with Doosan DX22

Effective training programs are essential for technicians and operators to maximize the use of the Doosan DX22. Comprehensive educational resources, simulation tools, and certification processes empower users with the knowledge and skills necessary to operate this advanced diagnostic tool.

Educational Programs

Doosan offers a range of educational programs designed to ensure that users gain proficiency in utilizing the DX22. These programs encompass various aspects of marine diagnostics, from basic operating procedures to advanced troubleshooting techniques.

- Workshops and Seminars: Interactive sessions focusing on the features and capabilities of the DX22.

- Online Courses: Flexible e-learning options that cover fundamental and advanced topics related to marine engine diagnostics.

- On-Site Training: Personalized training conducted at the user’s location, tailored to specific equipment and operational needs.

Simulator Features

The inclusion of simulator features within the training programs allows users to practice diagnostic scenarios in a risk-free environment. These simulations replicate real-world situations operators may face, helping to build confidence and expertise.

- Realistic Environment: Simulated engine conditions that match various make and model configurations.

- Interactive Learning: Hands-on experience in identifying and resolving common issues using intuitive interfaces.

- Performance Metrics: Immediate feedback on diagnostic skills to track progress and areas for improvement.

Certification Process

Achieving certification upon completion of training not only enhances credibility but also signifies a commitment to operational excellence. The certification process is designed to validate the skills acquired during training.

- Evaluation Tests: Assessments that measure understanding and capability in using the DX22 effectively.

- Certification Levels: Multiple tiers of certification allow users to advance their expertise based on experience and knowledge.

- Continued Education: Opportunities for recertification and further training to keep up with technological advancements and updates.

Software Update Mechanism

The Software Update Mechanism is a crucial aspect of maintaining the efficiency and effectiveness of the DX22. Regular updates ensure that the tool remains compatible with the latest engine models and incorporates new features that enhance its performance.

How to Update DX22

Updating the DX22 is a straightforward process designed to maximize user convenience. To perform an update, follow these steps:

- Connect the DX22 to a reliable internet source.

- Access the update menu through the device’s interface.

- Select the “Check for Updates” option.

- If updates are available, follow the prompts to download and install them.

This process ensures that users always have access to the most current software, which is essential for optimal performance and reliability.

Remote Installation via TeamViewer

For users who prefer assistance during the update process, remote installation support is available through TeamViewer. This service allows a qualified technician to guide users through the update steps remotely, ensuring that any potential issues can be addressed in real-time.

The benefits of using remote installation include:

- Expert guidance during the update process.

- Quick resolution of any difficulties encountered.

- Ensured compatibility with the latest engine technologies and features.

This service greatly enhances the user experience and helps maintain the tool’s functionality without requiring extensive technical knowledge from the user.

Schedule and Frequency of Updates

Updates for the DX22 are released periodically to incorporate the latest advancements in engine diagnostics and ensure regulatory compliance. Users are encouraged to check for updates monthly, although the actual frequency may vary based on developments in engine technology and feedback from the user community.

Regularly scheduled updates provide several advantages:

- Inclusion of new diagnostic capabilities.

- Fixes for any known software bugs.

- Improvements in user interface for easier navigation.

Keeping the software up to date is essential for maximizing the functionality and longevity of the DX22.

Troubleshooting common issues is a critical aspect of maintaining the efficiency and functionality of the Doosan Diagnostic Tool DX22. Understanding and resolving these problems can minimize downtime and enhance overall productivity.

Troubleshooting Common Issues

Connection Problems

Connection issues often arise during the use of diagnostic tools. These problems can stem from various sources, impacting the overall performance and effectiveness of the DX22.

-

Check Physical Connections

Ensure that all cables are securely connected to both the diagnostic tool and the engine’s ECU. Loose or corroded connections can cause intermittent issues.

-

Verify Network Settings

For tools that utilize wireless connectivity, confirm that the network settings are correctly configured. Incorrect Wi-Fi or Bluetooth settings can prevent successful connections.

-

Restart Devices

A simple restart of both the DX22 tool and the connected devices can often resolve minor connectivity problems. This can refresh the communication between devices.

Software Glitches

Software glitches can disrupt the functionality of the diagnostic tool, causing delays in data processing and other operational inconveniences.

-

Update Software

Ensure that the DX22 is running the latest software version. Updates often contain bug fixes that can resolve known issues and enhance performance.

-

Clear Cache

Clearing the software cache may help to eliminate temporary files that can slow down operations and cause glitches. This can often be performed within the software settings.

-

Factory Reset

If persistent glitches occur, performing a factory reset may restore original settings and resolve deep-seated software issues. Backup important settings before executing this step.

Diagnostic Errors

Diagnostic errors can prevent accurate readings and conclusions from the tool. Addressing these errors is essential for effective maintenance and troubleshooting.

-

Diagnose Error Codes

Review the error codes displayed by the DX22. Refer to the user manual for specific definitions and troubleshooting steps related to each code.

-

Recheck Engine Compatibility

Ensure that the tool is compatible with the engine model being diagnosed. Using the tool on an unsupported engine can lead to incorrect readings and errors.

-

Consult Error Documentation

If certain errors continue to appear, consult the diagnostic tool’s documentation for troubleshooting steps tailored specifically to those errors.

Technical Support and Service

Having access to reliable technical support and service is crucial for maximizing the potential of any advanced diagnostic tool. Users can rely on a comprehensive support framework designed to ensure optimal performance and troubleshoot issues effectively.

Remote Assistance Availability

The availability of remote assistance is a significant advantage for users, allowing quick and efficient resolution of issues without the need for on-site visits. This feature is particularly beneficial for maritime operations that may occur in remote locations.

- Remote support can be accessed through various platforms, ensuring a seamless experience.

- Trained technicians are equipped to provide assistance via remote desktop software.

- Real-time troubleshooting minimizes downtime, which is critical in marine applications.

Contacting Doosan Support

Efficient communication with support teams is essential for resolving any issues that may arise during operation. Doosan provides multiple channels for customers to reach their support team.

- Email support for inquiries and non-urgent issues.

- Phone support for immediate guidance and assistance during critical situations.

- Online resources including FAQs and troubleshooting guides available on the official website.

Warranty and Service Agreements

Understanding warranty and service agreements is vital for users to ensure they are protected against any potential defects or failures. Doosan offers clear guidelines related to these agreements.

- The warranty typically covers manufacturing defects and specific parts for a designated period.

- Service agreements provide ongoing maintenance support and can include additional benefits such as priority service.

- Terms and conditions should be reviewed to maximize the value of both the warranty and service agreements.

Achieving Regulatory Compliance

Ensuring compliance with regulatory standards is essential for marine operations. This section discusses emissions standards, safety regulations, and environmental considerations that impact the use of marine diagnostic tools.

Emissions Standards

Adhering to emissions standards is crucial for reducing the environmental impact of marine engines. These standards are set by various regulatory bodies and vary by region. Compliance ensures that engine operations do not exceed permissible emission limits.

Key aspects of emissions standards include:

- Regulatory Compliance: Familiarity with local, national, and international regulations helps ensure adherence to the required emissions limits.

- Emission Testing: Regular testing and diagnostics must be performed to verify engine performance and emissions outputs.

- Adoption of Clean Technologies: Utilizing technologies such as selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) to reduce harmful emissions is increasingly important.

Safety Regulations

Compliance with safety regulations is paramount in the marine industry. These regulations are designed to ensure the safety of personnel and vessels while promoting operational efficiency.

Key safety regulations include:

- Equipment Standards: All diagnostic tools, including marine engine analyzers, must meet established safety standards to minimize risks.

- Operational Procedures: Proper training and adherence to safety procedures are vital to ensure that personnel correctly operate diagnostic tools without incidents.

- Emergency Protocols: Clear protocols must be established and practiced to address any emergencies that may arise during operations.

Environmental Considerations

Incorporating environmental considerations is essential for sustainable maritime operations. The regulatory landscape emphasizes the need to protect marine ecosystems while ensuring compliance with environmental laws.

Important aspects include:

- Waste Management: Proper disposal and management of hazardous materials, including oil, chemicals, and waste products from engine operations, are critical to avoid environmental contamination.

- Noise Pollution: Compliance with regulations related to noise pollution can minimize disturbances to marine wildlife and surrounding communities.

- Continuous Monitoring: Utilizing diagnostic tools that enable real-time monitoring can aid in maintaining compliance with environmental standards.

Future Trends in Marine Diagnostics

As the marine industry continues to evolve, innovative diagnostic solutions are becoming essential. The integration of advanced technologies is paving the way for increased efficiency and reliability in marine operations.

Integration with IoT

The Internet of Things (IoT) is revolutionizing the way marine diagnostics are conducted. By connecting vessels and equipment to the internet, real-time data can be collected and analyzed for better decision-making.

- IoT devices enable continuous monitoring of engine parameters, allowing for immediate detection of anomalies.

- This data-driven approach facilitates proactive maintenance strategies, reducing unexpected failures.

- Integration with remote troubleshooting systems enhances support capabilities, ensuring swift resolutions to issues.

Predictive Maintenance

Predictive maintenance is gaining traction within the marine sector, driven by advancements in diagnostic technologies. By utilizing data analytics, marine operators can predict potential failures before they occur.

- Leveraging historical performance data, predictive algorithms identify trends and patterns in engine behavior.

- This foresight allows for more effective scheduling of maintenance activities, optimizing resource allocation.

- By transitioning from reactive to predictive maintenance, fleets can significantly improve reliability while minimizing downtime.

Enhanced Connectivity Features

Future diagnostic tools will increasingly emphasize connectivity, allowing seamless integration with various marine systems and devices. Enhanced connectivity features are essential for comprehensive diagnostics.

- Support for multiple communication protocols will facilitate interoperability among various brands and models of marine machinery.

- Remote access capabilities will allow technicians to perform diagnostics and maintenance without needing to be physically present on the vessel.

- This level of connectivity fosters collaboration between teams and enhances the overall effectiveness of diagnostic processes.

Customer success stories illustrate the impact of the DX22 in various maritime operations. These case studies highlight practical applications and the positive feedback from users who have integrated this tool into their maintenance and management practices.

Customer Success Stories with DX22

Case Studies

Numerous organizations have reported significant transformations in their operational efficiency after implementing the DX22. Here are a few notable case studies:

-

Case Study 1: Fleet Optimization for a Fishing Company

A prominent fishing company struggled with frequent engine failures and downtime. By utilizing the DX22, they implemented predictive maintenance strategies that enabled timely diagnostics and repairs. As a result, the company noted a 40% reduction in engine-related downtime within the first six months.

-

Case Study 2: Improved Maintenance Scheduling for a Shipping Line

A major shipping line revamped its maintenance scheduling using the DX22’s real-time monitoring features. This proactive approach led to a 30% reduction in maintenance costs and improved overall fleet performance, ensuring timely deliveries and customer satisfaction.

-

Case Study 3: Training Program for Engine Technicians

A maritime training institute adopted the DX22 as part of their curriculum for aspiring technicians. The interactive features and real-time data monitoring helped students gain hands-on experience. Graduates reported being better prepared for industry challenges, thus enhancing their employability.

Testimonials

Feedback from users who have integrated the DX22 into their operations reveals satisfaction and appreciation for the tool’s capabilities:

-

Testimonial 1: Fleet Manager

“The DX22 has entirely changed how we approach maintenance. The accuracy of diagnostics has saved us time and money, and we can’t imagine operating without it now.”

-

Testimonial 2: Chief Engineer

“Using the DX22 has improved our response times to engine issues significantly. The tool has proven its worth time and again, especially during peak seasons.”

-

Testimonial 3: Training Coordinator

“Integrating the DX22 into our training programs has allowed our students to engage with real-world scenarios. Their confidence and competence have soared since we started using this tool.”

Lessons Learned from Users

Feedback has led to valuable insights and lessons for current and potential users of the DX22:

- Importance of Regular Training: Continual training on new updates and features maximizes the tool’s potential.

- Emphasizing Preventive Maintenance: Users have learned that shifting to a preventive maintenance mindset creates substantial long-term savings.

- Integration with Existing Systems: Successful users recommend properly integrating the DX22 with other management systems to enhance data utilization and operational efficiency.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R5 [2024.03] The Doosan Diagnostic Tool DX22 Electronic Marine ECU Analyzer 01.00R5 [2024.03] is designed for optimal engine performance in marine applications. This tool offers advanced diagnostic capabilities and is compatible with a variety of marine engines. It plays a crucial role in maintaining and managing engine health. The latest version includes features that enhance connectivity and user experience, making it a valuable asset for marine operators and technicians.](https://ecmtrucks.com/wp-content/uploads/2024/08/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-ECU-ANALYZER-01.00R5-2024.03.png)

Reviews

Clear filtersThere are no reviews yet.