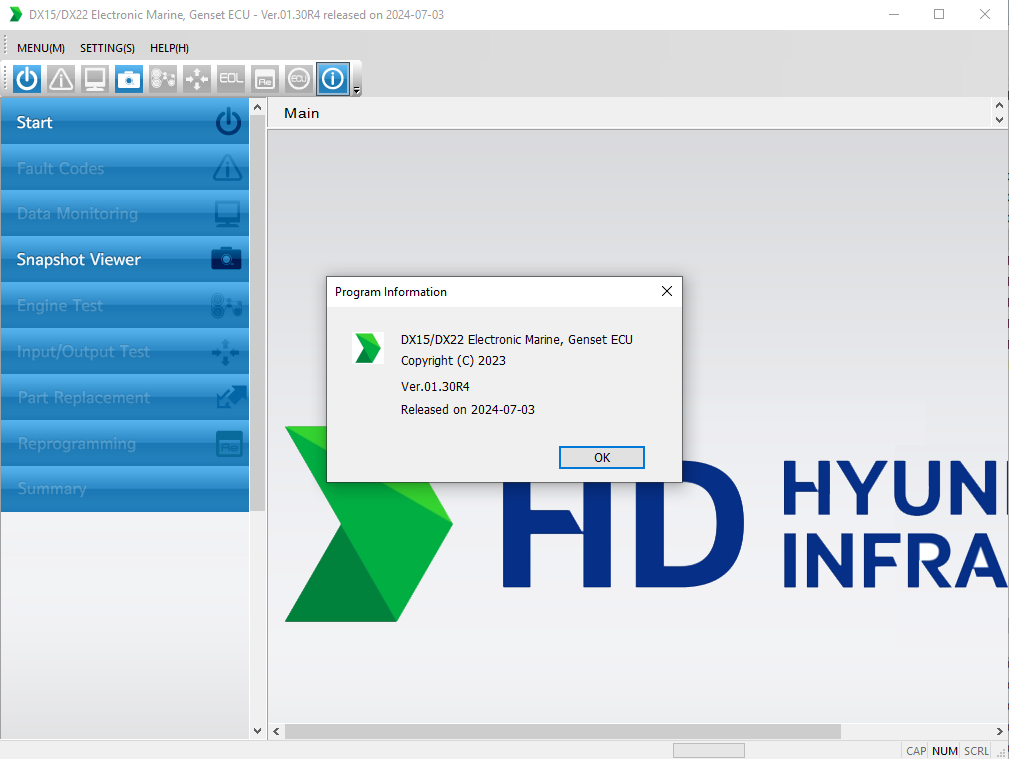

DOOSAN DIAGNOSTIC TOOL DX15 DX22 ELECTRONIC MARINE GENSET ECU 01.30 R4 [2024.07] : Revolutionizing Marine Maintenance

The DOOSAN DIAGNOSTIC TOOL DX15 DX22 is an advanced diagnostic solution for electronic marine generators. Launched in 2024, it offers features designed to improve maintenance and operational efficiency in the marine industry. This tool enhances performance through comprehensive diagnostics, enhanced connectivity, and real-time data monitoring. Its innovative design supports technicians in identifying issues quickly, ensuring reliable operation of marine equipment.

Table of Contents

ToggleThe Evolution of Marine Diagnostic Tools

The development of marine diagnostic tools has dramatically changed how vessels are maintained and operated. From rudimentary techniques to sophisticated technologies, the evolution has paved the way for improved efficiency and safety in marine environments.

Historical Context

Marine diagnostic tools have a rich history that dates back several decades. Initially, diagnostics relied on basic mechanical skills and manual inspections. Technicians would often depend on their intuition and experience to identify issues.

As the maritime industry progressed, the need for more effective diagnostic methods became apparent. The introduction of electronic systems marked a turning point, paving the way for tools that could communicate data from various components of marine systems.

The Role of Technology in Marine Diagnostics

Technology has played a crucial role in transforming marine diagnostics. Initially characterized by manual gauges and simple instruments, the landscape has shifted towards advanced electronic systems equipped with diagnostic capabilities.

Modern tools integrate various technologies, such as:

- Digital sensors that provide real-time data on engine performance.

- Software applications that analyze complex data sets for quicker troubleshooting.

- Networking capabilities allowing multiple components to communicate seamlessly.

These advancements enable a holistic approach to diagnostics, where data is not only available but also interpretable in real-time, enhancing decision-making for operators.

The Need for Advanced Diagnostic Tools

The complexities of contemporary marine engines and generator systems necessitate advanced diagnostic tools. With vessels becoming more reliant on sophisticated electronic systems, maintaining efficiency while minimizing downtime has become paramount.

Various factors contribute to the growing demand for such tools:

- Increased regulatory requirements for emissions and safety standards.

- The need for proactive maintenance strategies to prevent costly failures.

- Growing competition in the shipping and maritime industries, which drives the need for operational efficiency.

Ultimately, advanced diagnostic tools not only guarantee better performance and reliability but also serve as integral assets for the sustainable future of the maritime industry.

Introduction to DOOSAN DIAGNOSTIC TOOL DX15 DX22

The DOOSAN DIAGNOSTIC TOOL DX15 DX22 is a state-of-the-art diagnostic solution that offers unparalleled support for marine generators. Its sophisticated design and functionality streamline maintenance processes for a wide array of marine applications.

Company Background: DOOSAN

DOOSAN is a global leader in engineering and technology, recognized for its commitment to innovation and excellence since its establishment in 1896. Over the years, the company has diversified its expertise across various sectors, including construction, manufacturing, and marine systems. DOOSAN’s strong foundation in heavy machinery and engineering has enabled it to translate advancements into specialized solutions for the marine industry.

The company continues to invest in cutting-edge technologies that address the evolving needs of its customers. This dedication to research and development has positioned DOOSAN as a trusted partner for maritime solutions, fostering a collaborative approach to enhancing operational efficiency and safety.

Overview of the DX15 DX22 Tool

The DOOSAN DIAGNOSTIC TOOL DX15 DX22 is specifically engineered to provide comprehensive diagnostic capabilities for marine generators, ensuring optimal performance and reliability. The tool serves as a crucial element for technicians managing the complexities of various marine applications.

Key attributes of the DX15 DX22 include:

- Advanced diagnostic features that cover both mechanical and electrical systems.

- An intuitive user interface designed for easy navigation and effective data analysis.

- Enhanced connectivity options that allow integration with existing monitoring systems.

Each aspect of the DX15 DX22 reflects DOOSAN’s commitment to leveraging technology to solve real-world challenges faced by marine operators.

Offering both real-time monitoring and historical data analysis, the DX15 DX22 gives operators valuable insights into generator performance. The tool not only identifies issues but also provides recommendations for maintenance and optimization.

Key Features and Specifications

The DOOSAN DIAGNOSTIC TOOL DX15 DX22 incorporates advanced technology designed to improve diagnostic efficiency and streamline operations within marine environments. Its features focus on user-friendly interfaces, comprehensive diagnostics, and enhanced connectivity capabilities.

Advanced User Interface

The user interface of the DX15 DX22 tool has been developed with usability in mind. It emphasizes straightforward navigation and clarity to ensure that technicians can efficiently access critical information.

Intuitive Navigation

The tool features an intuitive navigation system that allows users to easily move through various operational functions. This design minimizes the learning curve for new users and ensures that experienced technicians can perform diagnostics swiftly.

User-Friendly Design

With a visually appealing interface, the layout of the software is designed to facilitate quick access to diagnostic tools and reports. The color coding of alerts and notifications enhances quick reactions to emerging issues, making it a practical choice for operators.

Comprehensive Diagnostic Capabilities

This tool boasts robust diagnostic functionalities that cover a wide range of systems. These capabilities are essential for ensuring the reliability and efficiency of marine generators.

Mechanical System Diagnostics

The DX15 DX22 is equipped to perform in-depth mechanical system diagnostics. It can assess the integrity of mechanical components, identifying issues such as wear or misalignment that could lead to equipment failure.

Electrical System Diagnostics

Electrical diagnostics are crucial for the overall performance of marine generators. This tool can analyze electrical systems to pinpoint faults, ensuring that all circuits and connections function optimally.

Enhanced Connectivity

Connectivity is a vital aspect of modern diagnostic tools, and the DX15 DX22 does not fall short. It supports various integration options to keep up with technological advancements within marine operations.

Platform Compatibility

The DX15 DX22 offers compatibility with multiple platforms, ensuring that it can be seamlessly integrated into existing monitoring systems. This flexibility enhances its usability across different marine applications.

Real-Time Monitoring

One of the standout features is its ability to provide real-time monitoring of generator performance. This function allows for immediate insight into operational parameters, enabling proactive management of potential issues.

Diagnostic Efficiency and Performance

Efficiency in diagnostics and performance is paramount in ensuring optimal operation of marine generators. The DOOSAN DX15 DX22 tool excels in real-time data analysis and comprehensive historical data management, providing invaluable insights into the performance and health of marine equipment.

Real-Time Data Analysis

Real-time data analysis is essential for effective monitoring and maintenance of marine generator systems. This feature allows operators to access critical performance metrics instantly, ensuring quick response times to any operational anomalies. The tool’s ability to analyze data as it is generated optimizes operational efficiency and facilitates proactive maintenance.

Key benefits of real-time data analysis include:

- Immediate identification of operational issues, leading to faster interventions.

- Continuous monitoring of key metrics such as load, temperature, and fuel efficiency.

- Real-time alerts that notify users of potential failures or inefficiencies.

Historical Data Storage and Analysis

The capability to store and analyze historical data is a crucial aspect of the DOOSAN DX15 DX22 tool. By maintaining a comprehensive database of performance data over time, technicians can identify trends, predict failures, and enhance the overall reliability of marine generators.

Utilizing historical data effectively leads to improved decision-making and operational strategies.

Data Retrieval Methods

Data retrieval from the system is straightforward and user-friendly, allowing technicians to access historical performance information without unnecessary complexity. The tool features efficient data querying capabilities, enabling users to:

- Search for specific time frames or operational conditions.

- Retrieve detailed reports on generator performance across various metrics.

Long-Term Performance Tracking

Long-term performance tracking is vital for maintaining the integrity and efficiency of marine generators. By leveraging historical data, operators can monitor changes in performance over extended periods.

Long-term analytics provide insights into:

- Identifying chronic issues or recurrent failures, thus helping in preventive maintenance.

- Assessing the impact of operational changes on generator performance.

- Evaluating the effectiveness of maintenance interventions over time.

Software updates and support are crucial components in ensuring optimal performance and functionality of the diagnostic tools. Keeping software up to date enhances capabilities, ensures compatibility, and addresses any potential issues swiftly.

Software Updates and Support

Continuous Software Updates

The DOOSAN Diagnostic Tool DX15 DX22 is designed with an emphasis on continuous improvement through regular software updates. These updates can include enhancements to diagnostic algorithms, new functionalities, bug fixes, and improvements in user experience. The commitment to provide ongoing support assures that the tool remains effective and relevant as technology evolves.

Updates can be seamlessly integrated into the tool without disrupting operations. Users receive notifications regarding available updates, which ensures that they always have access to the latest features and improvements. This proactive approach contributes significantly to maintaining high levels of efficiency and functionality.

Remote Installation via TeamViewer

Remote installation support is an essential feature that simplifies the update process for users. Through TeamViewer, technicians can assist in the installation and configuration of software remotely. This capability not only saves time but also allows for immediate troubleshooting and resolution of any issues that may arise during installation.

Step-by-Step Guide

- Download TeamViewer from the official website.

- Install TeamViewer on the device connected to the DOOSAN tool.

- Share the unique ID and password with the remote technician.

- Allow the technician to access the system remotely to perform the installation.

- Follow the prompts given by the technician for successful configuration.

Benefits of Remote Support

Utilizing remote support offers numerous advantages, including:

- Time Efficiency: Quick access to expert support without the need for on-site visits.

- Cost-Effective: Reducing travel costs associated with in-person technical support.

- Expert Assistance: Access to knowledgeable technicians who can guide users through complex processes.

- Immediate Troubleshooting: Problems can be resolved on the spot, minimizing downtime.

This integration of technology helps ensure that users can fully benefit from the capabilities of the DOOSAN Diagnostic Tool while easily managing updates and support needs.

Advanced Diagnostic Functions

Advanced Diagnostic Functions enhance the effectiveness and reliability of marine generator operations. These capabilities allow technicians to conduct in-depth analyses, accurately identify issues, and provide insight into generator performance under various conditions.

Fault Analysis and Identification

This feature focuses on the systematic approach to detect and resolve faults in marine generators. Fault analysis ensures that issues are identified promptly, minimizing potential operational disruptions.

Error Code Detection

The DX15 DX22 incorporates sophisticated algorithms for error code detection, enabling quick identification of malfunctions. This system scans multiple components and subsystems, providing a comprehensive overview of generator status. The abstraction of fault codes allows technicians to pinpoint specific areas requiring attention.

Recommended Solutions

Upon detection of an error code, the tool offers tailored recommendations for corrective actions. These may include steps for immediate troubleshooting, instructions for component replacements, or guidance on conducting further diagnostics. This feature significantly streamlines the maintenance process and reduces downtime.

Condition Simulations

Condition simulations provide an invaluable resource for predicting how marine generators will perform under a variety of operational scenarios. This functionality ensures that operators are prepared for different environments and load conditions.

Load and Environmental Simulation

The simulation capabilities allow users to model various load scenarios, assessing how changes in demand affect generator performance. It also includes environmental simulations that consider factors such as temperature, humidity, and sea conditions, ensuring comprehensive preparedness.

Preparing for Unexpected Situations

Through advanced simulations, technicians can anticipate potential challenges that may arise during operation. Preparing for unexpected situations, such as sudden load changes or adverse weather, enhances the safety and efficacy of marine operations.

Detailed Report Generation

Comprehensive report generation enables operators and technicians to document diagnostic results systematically. This function supports ongoing maintenance and strategic planning for equipment longevity.

Report Features

The detailed reports generated by the DX15 DX22 include insights into system health, historical performance data, and recommendations for maintenance activities. This feature allows users to analyze trends over time, facilitating proactive rather than reactive maintenance strategies.

Planning Maintenance

Utilizing the data derived from detailed reports, maintenance can be strategically planned to ensure operational efficiency. By analyzing report information, operators can schedule service intervals based on actual performance metrics, thereby optimizing maintenance costs and reducing the likelihood of unexpected failures.

Applications in the Marine Industry

The DOOSAN diagnostic tool is widely applicable across various sectors of the marine industry. Its versatility allows for efficient maintenance and monitoring of diverse marine vessels, ensuring optimal performance and reliability.

Yachts and Luxury Vessels

For yachts and luxury vessels, the importance of reliable power generation cannot be overstated. These ships require high-quality electrical systems to support amenities that enhance passenger comfort and safety. The DOOSAN diagnostic tool plays a crucial role in maintaining these systems by:

- Performing comprehensive diagnostics to address any mechanical or electrical issues promptly.

- Allowing for real-time data monitoring to ensure systems operate within optimal parameters.

- Generating detailed reports that help yacht operators plan maintenance schedules effectively.

With the tool’s advanced capabilities, yacht owners can minimize downtime, ensuring a seamless experience for their guests while maximizing the performance of their vessels.

Cargo and Transport Ships

Cargo and transport ships rely heavily on efficient power systems to meet the growing demands of global trade. The DOOSAN diagnostic tool enhances the operational reliability of these vessels by:

- Facilitating proactive maintenance through real-time monitoring and fault analysis, preventing costly breakdowns.

- Supporting compliance with industry regulations by providing diagnostics related to emissions and overall system performance.

- Offering solutions for various power generation scenarios, adapting to the diverse operational requirements of transport vessels.

By addressing diagnostic needs effectively, the tool ensures that cargo ships can maintain schedules and deliver goods safely and on time.

Commercial Fishing Boats

In the commercial fishing industry, the reliability of power systems is vital, as fishing operations often take place in harsh and unpredictable environments. The DOOSAN diagnostic tool aids in the maintenance of fishing boats by:

- Enabling swift fault detection to minimize disruption during critical fishing activities.

- Tracking long-term performance data, allowing operators to make informed decisions regarding equipment upgrades and replacements.

- Providing detailed feedback on engine performance and fuel efficiency, crucial for maintaining profitability in fishing operations.

As a result, commercial fishing boats can operate more effectively, ensuring both profitability and safety for crew members at sea.

Benefits of Using the DX15 DX22

The DX15 DX22 offers numerous benefits that enhance marine operations. From minimizing downtime to improving safety measures, this tool provides solutions that address various operational challenges within the marine industry.

Reduced Downtime

One of the most significant advantages of utilizing the DX15 DX22 is the reduction in downtime for marine generators. Quick and precise diagnostics enable technicians to pinpoint issues rapidly, preventing prolonged periods of inoperability. With the ability to identify malfunctions before they escalate, the tool helps maintain a seamless operation.

- Fast problem identification minimizes repair time.

- Predictive maintenance features alert operators to potential failures early.

- Streamlined processes allow for quicker access to solutions and repairs.

Increased Operational Efficiency

Operational efficiency is vital in the marine industry, where delays can result in substantial financial losses. The DX15 DX22 facilitates enhanced efficiency through integrated monitoring systems and real-time data analysis. These features enable operators to make informed decisions that optimize performance.

- Access to real-time performance metrics supports timely adjustments.

- Enhanced connectivity options allow for comprehensive monitoring.

- Optimized performance data helps in fuel management and usage.

Cost Savings in Maintenance

Cost savings are a direct benefit of employing the DX15 DX22 in marine operations. With a focus on preventive maintenance, this tool helps operators plan service proactively rather than reactively, which can be more costly. Efficient diagnostics and solutions lead to less repetitive work and material waste.

- Effective diagnostics reduce unnecessary repairs and replacement costs.

- Consolidated maintenance strategies save money over time.

- Data-driven decisions lead to better use of resources.

Improved Safety

Safety is paramount in marine operations, and the DX15 DX22 plays an essential role in enhancing safety protocols. By ensuring that all systems are functioning correctly, the tool mitigates risks associated with equipment failure, which can lead to dangerous situations at sea.

- Regular diagnostics help maintain compliance with safety standards.

- Adequate reporting enables comprehensive maintenance logs.

- Proactive issue resolution decreases incident risk.

Addressing User Questions

In the ever-evolving landscape of marine diagnostics, users often have specific inquiries regarding functionality and performance. Addressing these questions is crucial for maximizing the efficiency of diagnostics tools in marine applications.

Common Issues Diagnosed by the DX15 DX22

Users frequently report a variety of issues that can be effectively diagnosed by the DX15 DX22 tool, ensuring that potential problems are identified early. Common issues include:

- Electrical system faults: This includes voltage irregularities, wiring issues, and equipment failures, which can be detected swiftly through comprehensive diagnostics.

- Mechanical malfunctions: Problems such as excessive wear or component failures in the engine can be diagnosed for timely repairs, preventing larger failures later.

- Performance anomalies: Irregular performance metrics, such as inconsistent power output or fuel efficiency drops, can easily be identified, allowing for immediate corrective action.

- Cooling system issues: Identification of leaks or blockages in the cooling system is essential for maintaining operational integrity and preventing overheating.

Differences Between DX15 and DX22 Models

While both DX15 and DX22 models serve similar purposes in diagnostics, they exhibit key differences that cater to various user needs. The distinctions include:

- Diagnostic range: The DX22 supports a broader array of diagnostic functions compared to the DX15, making it suitable for more complex systems.

- User interface: The DX22 features a more advanced user interface that enhances ease of use, particularly for those less familiar with marine diagnostics.

- Data connectivity: Enhanced connectivity options in the DX22 allow integration with more platforms, providing a seamless data monitoring experience.

- Real-time analysis capabilities: The DX22 offers superior real-time data analysis, empowering users with instant insights into system performance.

Integration with Existing Systems

Integration capabilities are essential for users leveraging existing marine systems. The DX15 DX22 tool is designed to be compatible with a wide range of systems, facilitating smooth integration and optimal performance. Key elements of this integration include:

- Platform versatility: The tool is compatible with various data systems, allowing it to function alongside different brands and models.

- Seamless data transfer: Utilizing advanced connectivity options, users can easily transfer data between the diagnostic tool and other marine management systems.

- Support for legacy systems: The DX15 DX22 maintains functionality with older systems, ensuring that users do not need to overhaul existing infrastructure.

Future Outlook for DOOSAN Diagnostic Tools

The future of DOOSAN diagnostic tools looks promising, marked by innovations and advancements aimed at enhancing the efficiency and reliability of marine diagnostics. As technology continues to evolve, DOOSAN is poised to incorporate cutting-edge features that meet the demands of the industry.

Upcoming Features and Enhancements

DOOSAN is actively working on a range of upcoming features designed to improve user experience and diagnostic capabilities. These enhancements will focus on several key areas:

- Enhanced Data Analytics: Future versions of the diagnostic tools will leverage advanced algorithms for deeper data analysis, allowing for more precise diagnostics and trend predictions.

- Improved User Interface: The interface is set to undergo significant upgrades, making it even more intuitive and accessible for users with varying levels of technical expertise.

- Integration of IoT Capabilities: With the growing relevance of the Internet of Things (IoT) in maritime technology, DOOSAN is exploring ways to integrate IoT features, enabling real-time monitoring and data sharing across platforms.

- Mobile Compatibility: Anticipated updates include enhanced mobile applications, providing users with the flexibility to monitor their systems from anywhere, thus increasing operational efficiency.

The Role of AI in Future Diagnostic Tools

Artificial Intelligence (AI) is expected to play a crucial role in the development of future DOOSAN diagnostic tools. The incorporation of AI technologies can facilitate:

- Predictive Maintenance: By analyzing historical and real-time data, AI can identify potential issues before they escalate, allowing for proactive maintenance strategies that reduce downtime.

- Automated Fault Detection: AI will enhance fault detection processes by automatically interpreting error codes and suggesting corrective actions, streamlining the troubleshooting process.

- Smart Data Management: AI algorithms will improve data organization and retrieval, enabling users to easily access relevant information when making maintenance decisions.

- Adaptive Learning: Future tools will employ machine learning techniques, allowing the systems to learn from past diagnostics, continuously improving their accuracy and effectiveness.

Comparing DX15 DX22 with Competitors

In the competitive landscape of marine diagnostic tools, the DX15 DX22 stands out for its innovative features and capabilities. Comparing this tool with its competitors reveals its advantages and how it meets the needs of the marine industry.

Key Competitive Advantages

The DOOSAN DX15 DX22 offers several key competitive advantages that distinguish it within the market:

- Comprehensive Diagnostic Capabilities: The DX15 DX22 provides detailed diagnostics for both mechanical and electrical systems, enabling faster identification and resolution of issues.

- User-Friendly Interface: Featuring an intuitive design, the user interface simplifies navigation and makes it accessible for technicians of varying skill levels.

- Enhanced Connectivity: With compatibility across multiple platforms, this tool allows for real-time monitoring, which is often not available in competitor models.

- Data Analysis Tools: The capacity for historical data storage combined with real-time analysis enables long-term performance tracking that competitors may lack.

- Regular Software Updates: Continuous updates ensure that users always have the latest features and solutions at their disposal, unlike some competitors who may have infrequent updates.

User Testimonials and Reviews

Feedback from users highlights the distinct advantages of the DX15 DX22 over its competitors. Many technicians have expressed their satisfaction with the tool’s performance:

- Reliability: Users consistently report high reliability in diagnostics, allowing for timely maintenance and reduced downtime.

- Efficiency: Many reviews mention that the tool has significantly improved the efficiency of their maintenance routines, leading to cost savings in the long run.

- Ease of Use: Technicians appreciate the straightforward navigation and ease of accessing features, which enhances their workflow.

- Support and Resources: Positive comments often reference the excellent customer support provided by DOOSAN, which includes remote installation assistance, facilitating a smooth experience for users.

This feedback underscores the DX15 DX22’s position as a leading choice for marine diagnostics, demonstrating its strengths against the offerings of competitors.

Installation and Setup

Proper installation and setup of the diagnostic tool are essential for optimal performance and reliability. This section outlines the necessary requirements and provides a comprehensive guide for installation.

Initial Setup Requirements

Before proceeding with the installation, it is crucial to ensure that certain prerequisites are met. These requirements help facilitate a smooth setup process:

- Ensure that the latest software version is downloaded from the manufacturer’s website.

- Confirm compatibility with the marine equipment being diagnosed.

- Check for sufficient system requirements on the device intended for use, including:

- Operating System: Windows 10 or later

- RAM: Minimum 4GB

- Storage: At least 1GB of free space

- Ports: USB port for connection

- Gather necessary tools, including a stable internet connection for online support, and USB cables for device connection.

- Prepare the marine generator for connection, ensuring it is in a safe and accessible location.

Step-by-Step Installation Guide

The installation process is designed to be straightforward, but following the steps carefully can prevent issues. Here’s a detailed guide to assist with the setup:

- Step 1: Software Installation

- Download the installation file from the official DOOSAN website.

- Locate the downloaded file and double-click to initiate the installer.

- Follow the on-screen prompts to install the software on the designated device.

- Step 2: Connecting the Tool

- Use the USB cable to connect the diagnostic tool to the device where the software is installed.

- Ensure a stable connection to avoid interruptions during the setup process.

- Power on the marine generator that will be diagnosed.

- Step 3: Configuration

- Open the installed software on the device.

- Select the appropriate marine generator model from the list provided.

- Adjust settings according to the specification of the generator to optimize functionality.

- Step 4: Initial Diagnostics

- Once configuration is complete, run an initial diagnostics test to ensure all systems are operational.

- Review the diagnostic report generated by the software for any issues or alerts.

- Step 5: Finalizing Setup

- After successful diagnostics, save the configuration settings for future use.

- Ensure that the tool is securely stored for easy access during regular maintenance checks.

By following this installation and setup guide, the DOOSAN diagnostic tool can be effectively utilized, enabling accurate diagnostics and improved maintenance capabilities for marine generators.

Training and Support Resources

Effective training and support resources play a crucial role in maximizing the use of advanced diagnostic tools in marine applications. Access to thorough training programs and online manuals ensures that technicians can utilize these technologies fully and efficiently.

Training Programs for Technicians

Comprehensive training programs are essential for technicians using the DOOSAN diagnostic tools. These programs are designed to equip individuals with the necessary skills and knowledge to operate and troubleshoot the tool effectively. Training sessions include:

- Hands-on workshops focusing on practical applications and real-world scenarios.

- Theoretical classes covering the underlying principles of marine diagnostics and tool functionalities.

- Certification programs that validate the technician’s competency in using the tool.

The training often includes a mix of interactive sessions with experienced instructors and self-paced online modules, allowing technicians to learn at their convenience. Regular evaluations ensure that participants grasp the material effectively and are prepared for challenges they may face in the field.

Online Resources and Manuals

In addition to in-person training, a wide range of online resources and manuals are available to support technicians. These include:

- User manuals that provide step-by-step guidance on operating the diagnostic tool and understanding its features.

- Online tutorials and video demonstrations covering specific functionalities, making it easier to grasp complex processes.

- FAQs and troubleshooting guides to help users address common issues quickly and efficiently.

Furthermore, technicians can access forums and community boards where they can share experiences, ask questions, and learn from others in the industry. This collaborative environment enhances the overall effectiveness of training and support, ensuring that all users have the tools they need to succeed in maximizing the functionalities of the diagnostic equipment.

Maintenance Best Practices Using the DX15 DX22

Implementing effective maintenance practices with the DX15 DX22 ensures optimal performance and longevity of marine generators. Utilizing both preventive and predictive strategies, the tool enhances the reliability of systems in demanding marine environments.

Preventive Maintenance

Preventive maintenance is essential to avoid unexpected failures and extend the lifespan of marine equipment. Regularly scheduled checks and servicing practices can keep systems running at peak efficiency.

- Regular inspections: Conduct systematic checks on both mechanical and electrical systems. This includes visual inspections for wear and tear, leaks, and corrosion.

- Scheduled servicing: Adhere to a timetable for routine maintenance tasks, such as oil changes, filter replacements, and coolant checks.

- Calibration of sensors: Regularly calibrate sensors and instrumentation to ensure accurate readings, which aids in identifying potential issues early.

- Documentation: Maintain comprehensive logs of all maintenance activities, observations, and any adjustments made to the systems.

Predictive Maintenance

Predictive maintenance leverages data collected by the DX15 DX22 to forecast potential failures before they occur. This approach minimizes downtime and repair costs by addressing issues proactively.

Using Data for Predictive Maintenance

The capability of the DX15 DX22 to collect and analyze data in real-time enables technicians to identify trends and anomalies that may indicate future problems. Critical data points include:

- Performance metrics: Monitor key performance indicators such as temperature, pressure, and load levels to detect deviations from normal operating conditions.

- Error codes: Utilize the tool’s error code detection to determine specific issues and implement preventive measures before failures happen.

- Historical analysis: Review historical data to understand patterns and predict when maintenance or component replacement will be necessary.

Case Studies

Several marine operations have successfully implemented predictive maintenance strategies using the DX15 DX22, showcasing its practical benefits:

- In a fishing fleet, operators who utilized predictive maintenance reported a 30% reduction in engine failures, resulting in significant savings and increased operational uptime.

- A luxury yacht service company integrated predictive methods into their routine. As a result, they optimized maintenance schedules based on data insights, reducing unnecessary service visits.

Environmental and Regulatory Compliance

Understanding environmental and regulatory compliance is essential in the marine industry. Compliance ensures that marine operations adhere to environmental standards, focusing on emissions reduction and overall sustainability. This section explores key aspects of emissions monitoring and compliance with industry standards.

Emissions Monitoring

Emissions monitoring is a crucial component of maintaining compliance within marine operations. It involves the systematic measurement and assessment of pollutants released into the atmosphere by marine generators. The DOOSAN DIAGNOSTIC TOOL DX15 DX22 is equipped with features that facilitate efficient emissions monitoring.

This tool enables operators to track emissions data in real-time, allowing for prompt action to stay within regulatory limits. Effective emissions monitoring helps in identifying trends, ensuring that operators can make informed decisions to minimize environmental impact. Key aspects of emissions monitoring include:

- Real-time data tracking: Provides continuous monitoring of emissions levels.

- Compliance reporting: Generates reports that demonstrate adherence to environmental regulations.

- Issue detection: Identifies anomalies and potential issues before they escalate.

Compliance with Marine Standards

Compliance with marine standards is not just about avoiding penalties; it is about fostering a culture of environmental responsibility. Adhering to established environmental regulations ensures that marine vessels operate sustainably, reducing their ecological footprint. This compliance is often guided by regulations set forth by organizations such as the International Maritime Organization (IMO) and local environmental authorities.

Key areas of focus for compliance include:

- Emission control areas (ECAs): Strict guidelines regarding emissions in designated regions.

- Ballast water management: Regulations targeting aquatic invasive species transfer through ballast water.

- Fuel quality standards: Requirements for low-sulfur fuel to minimize harmful emissions.

By integrating advanced diagnostic tools, operators can ensure that their vessels not only comply with existing regulations but also actively contribute to a cleaner marine environment. The combination of emissions monitoring and compliance adherence plays a vital role in achieving sustainability in marine operations.

Case Studies and Real-World Examples

The following case studies illustrate the effectiveness and reliability of the DOOSAN diagnostic tool in real-world marine applications. By analyzing actual scenarios, key insights into the impact of advanced diagnostic technology on operational success are highlighted.

Successful Diagnoses

Case studies demonstrate how the DOOSAN diagnostic tool efficiently identifies issues in marine generators, leading to quick resolutions and minimal downtime. Operational efficiency significantly improves through these interventions. The following examples showcase various scenarios:

-

Luxury Yacht Maintenance

A luxury yacht experienced unexpected fluctuations in generator output, impacting onboard systems. Utilizing the DOOSAN tool, technicians identified a fault in the voltage regulator. The prompt diagnosis allowed for immediate maintenance, restoring normal operations before guests noticed any inconvenience.

-

Cargo Ship Performance

A cargo ship, running a busy shipping route, faced intermittent operational disruptions due to generator issues. By using the DOOSAN diagnostic tool, the crew performed a thorough evaluation, which led to the discovery of increased wear in the alternator. Timely replacement prevented significant delays and maintained the schedule.

-

Commercial Fishing Fleet

A fishing vessel reported issues with its generator that affected its ability to operate fishing equipment reliably. The DOOSAN tool was utilized to diagnose inconsistencies in the fuel delivery system. Corrective actions based on diagnostics ensured that the vessel met its fishing quotas without further disruptions.

Customer Success Stories

Numerous customers have reported positive outcomes after implementing the DOOSAN diagnostic tool in their operations. These stories resonate within the marine industry, showcasing tangible benefits that underscore the tool’s value.

-

Case of the Research Vessel

A research vessel deployed in remote waters struggled with generator reliability. After incorporating the DOOSAN diagnostic tool, operators accessed real-time data and historical performance analytics. This critical information guided maintenance schedules and resulted in a 30% reduction in operational downtime over six months.

-

Charter Service Enhancements

A charter service added the DOOSAN diagnostic tool to enhance their fleet maintenance capabilities. As a result, they reported a drastic improvement in efficiency, allowing for better customer experiences. By actively monitoring generator performance, they could preemptively address issues, leading to zero cancellations due to generator failures in an entire season.

-

Marine Highways Initiative

In a state initiative aimed at enhancing marine transport efficiency, several vessels adopted the DOOSAN tool. The initiative led to standardized maintenance procedures and drastically improved communication between crews. Feedback from stakeholders indicated an increasing satisfaction rate due to reduced incidents and improved reliability across various vessels.

Frequently Asked Questions

This section addresses common inquiries related to the diagnostic tool, focusing on troubleshooting and specific features to enhance user understanding.

Troubleshooting Common Issues

Many users may encounter a variety of common issues when utilizing the diagnostic tool. Understanding how to address these problems can significantly improve the user experience. Below are some frequently faced challenges and their solutions:

-

Connectivity Problems

If the tool fails to connect to the generator’s ECU, ensure that all cables are securely plugged in. Verifying Wi-Fi settings and re-initiating the connection may also be necessary.

-

Software Glitches

Occasionally, users may experience software crashes. Regularly updating the software can mitigate these issues. If problems persist, restarting the device might help restore functionality.

-

Data Synchronization Issues

If real-time data is not displaying as expected, check the compatibility of the platform being used. Ensure the diagnostic tool is correctly linked to the monitoring system.

-

Error Code Detection

Unexpected error codes can arise during diagnostics. Refer to the error code guide within the tool to identify the issue and explore suggested troubleshooting steps.

User Queries on Features

Understanding the features of the diagnostic tool is crucial for effective operation. This section addresses common queries to provide clarity on the tool’s capabilities.

-

What kind of diagnostic capabilities does the tool offer?

The tool provides comprehensive diagnosis across mechanical and electrical systems. Users can receive detailed insights into each system’s performance, helping identify potential issues accurately.

-

How does the real-time monitoring feature work?

Real-time monitoring allows users to observe the performance of their systems live. Any deviations or irregularities in the data can be flagged, making it easier to address problems swiftly.

-

Can the tool generate detailed reports?

Yes, the diagnostic tool is capable of generating thorough reports that outline the condition of various systems over time. These reports are essential for tracking maintenance needs and overall system health.

-

What platforms can the tool integrate with?

The tool is designed for broad compatibility, allowing integration with various maritime monitoring systems. This expands the tool’s functionality and user convenience significantly.

Final Thoughts on the DOOSAN DX15 DX22

The DOOSAN DX15 DX22 marks a significant evolution in marine diagnostic technology. Its advanced features and capabilities provide valuable insights for operators and technicians, enhancing maintenance processes and operational efficiency.

Summarizing Key Points

The DX15 DX22 tool stands out due to several critical attributes:

- Innovative Diagnostics: The tool utilizes modern algorithms and comprehensive data analysis for quick fault identification and resolution.

- User-Centric Design: Its intuitive interface allows users, regardless of skill level, to navigate easily and efficiently access essential functions.

- Real-Time Monitoring: Continuous data collection and analysis facilitate proactive maintenance, minimizing potential downtimes.

- Robust Connectivity: Compatibility with various platforms ensures seamless integration into existing marine systems, enhancing overall performance.

- Regular Software Updates: Ongoing enhancements and remote installation support through TeamViewer help keep the tool state-of-the-art and responsive to users’ needs.

Looking Ahead

The future of marine diagnostics with tools like the DX15 DX22 is promising. With advancements in technology and data analytics, the potential for enhanced performance and reliability is greater than ever. Key areas for future development may include:

- Artificial Intelligence Integration: The incorporation of AI could lead to more sophisticated predictive maintenance capabilities, allowing for higher operational efficiency.

- Expanded Connectivity: Future iterations may offer increased compatibility with emerging maritime technologies and platforms.

- Enhanced Reporting Features: Improvements in reporting tools can provide more detailed insights for long-term maintenance planning and resource allocation.

- Environmental Compliance Tools: Further developments could focus on ensuring compliance with evolving marine environmental regulations, aiding operators in sustainable practices.

As the industry continues to evolve, the DOOSAN DX15 DX22 will likely remain at the forefront, facilitating better decision-making and enhancing safety across maritime operations.

![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE DCU ANALYZER 01.00 R3 [2024.04]](https://ecmtrucks.com/wp-content/uploads/2024/08/Capture-150x150.png) DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE DCU ANALYZER 01.00 R3 [2024.04]

DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE DCU ANALYZER 01.00 R3 [2024.04] Bendix Acom Pro Diagnostic Software 2023

Bendix Acom Pro Diagnostic Software 2023![DOOSAN DIAGNOSTIC TOOL DX22 GENERATOR ENGINE 00.13 [2023.06]](https://ecmtrucks.com/wp-content/uploads/2024/08/3-150x150.png) DOOSAN DIAGNOSTIC TOOL DX22 GENERATOR ENGINE 00.13 [2023.06]

DOOSAN DIAGNOSTIC TOOL DX22 GENERATOR ENGINE 00.13 [2023.06]![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R5 [2024.03]](https://ecmtrucks.com/wp-content/uploads/2024/08/DOOSAN-DIAGNOSTIC-TOOL-DX22-ELECTRONIC-MARINE-ECU-ANALYZER-01.00R5-2024.03-150x150.png) DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R5 [2024.03]

DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.00R5 [2024.03]![DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.30R1 [2024.06]](https://ecmtrucks.com/wp-content/uploads/2024/08/1-2-150x150.png) DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.30R1 [2024.06]

DOOSAN DIAGNOSTIC TOOL DX22 ELECTRONIC MARINE ECU ANALYZER 01.30R1 [2024.06]

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

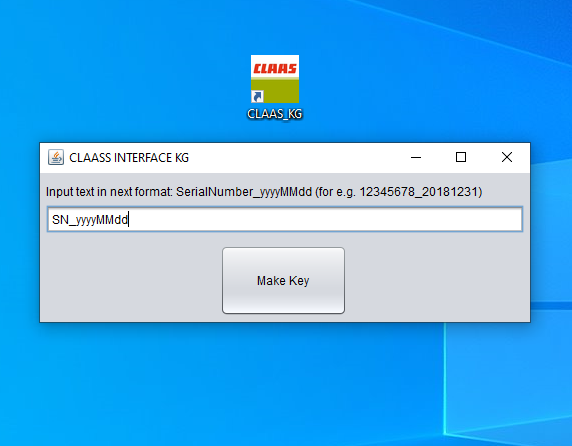

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

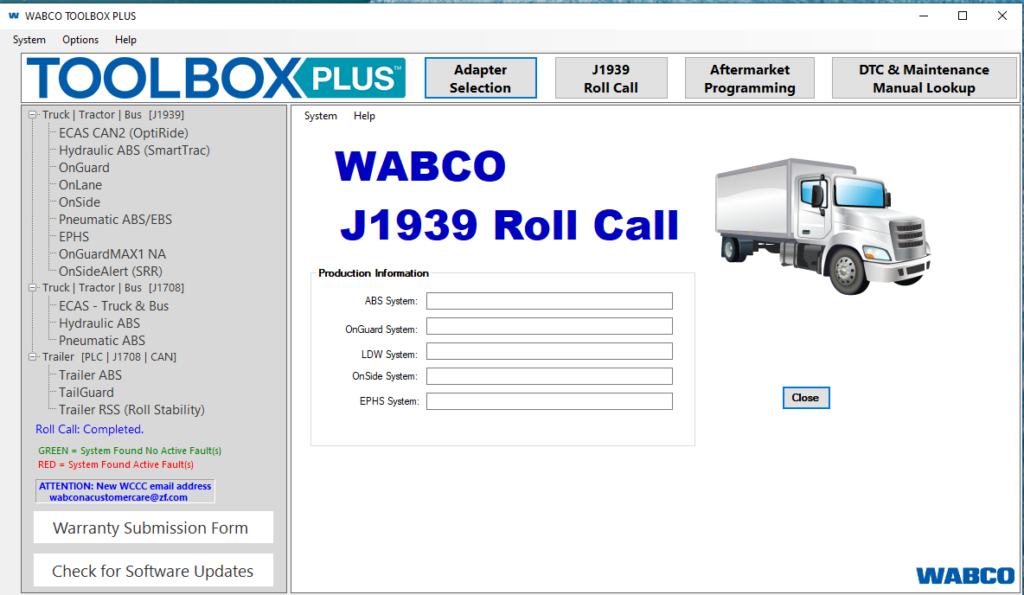

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR