NAVISTAR NED 2024: The Future of Engine Diagnostics and Programming

NAVISTAR NED 2024 is an advanced diagnostic and programming tool designed specifically for Navistar engines. It offers a comprehensive suite of features that support technicians in efficiently maintaining and optimizing engine performance. This software enhances diagnostic capabilities, programming functions, and real-time monitoring. It is essential for ensuring that fleets operate smoothly, reducing downtime, and maximizing operational efficiency.

Understanding NAVISTAR NED 2024

The NAVISTAR NED 2024 platform serves as an integral tool in engine diagnostics and programming. It streamlines the process and enhances the efficiency of maintenance practices.

Key Features of NAVISTAR NED 2024

- Advanced diagnostic capabilities allowing for comprehensive fault analysis.

- Real-time data monitoring to assess engine performance continuously.

- User-friendly interface that simplifies navigation and operation.

- Periodic updates to ensure the latest features and standards are maintained.

Advantages Over Previous Versions

Compared to earlier iterations, NAVISTAR NED 2024 provides significant improvements in usability and functionality. The platform integrates more advanced features that enhance troubleshooting and optimization processes.

Some notable advantages include:

- Improved diagnostic accuracy leading to faster resolution of issues.

- Expanded compatibility with a wider range of engine models.

- Streamlined programming functions for better fuel efficiency.

Diagnostic Capabilities

Effective diagnostic capabilities are essential for maintaining engine performance and reliability. The advanced diagnostic functions enable mechanics to quickly identify and resolve issues, ensuring minimal downtime for vehicles.

Engine Diagnostics Explained

This section delves into the various aspects of engine diagnostics, outlining how the tool facilitates comprehensive analyses of engine health. The diagnostic features help in pinpointing issues at an early stage, thus preventing further complications.

Comprehensive Diagnostic Tools

The suite of diagnostic tools includes:

- Real-time monitoring of engine parameters

- Analyzing functionality through specialized diagnostic tests

- Guided troubleshooting procedures for efficient assessments

These tools work cohesively to provide a thorough understanding of engine performance and potential failures.

Diagnostic Trouble Codes Analysis

The ability to read and interpret diagnostic trouble codes (DTCs) is crucial. This analysis includes:

- Extracting codes from the engine control unit (ECU)

- Understanding the meaning of specific codes for targeted repairs

- Clearing codes after issues are addressed to reset the system

Through effective DTC analysis, technicians can ensure that issues are promptly resolved, enhancing overall engine longevity.

Advanced Programming Functions

Advanced Programming Functions enhance the effectiveness of engine management and operational efficiency. These functions allow users to customize engine performance according to specific needs and requirements.

Programming Service and Updates

This feature enables technicians to program essential services and stay updated with the latest engine software. Regular updates are crucial for maintaining peak engine performance and adapting to evolving industry standards.

Change Programming for Optimization

Customization options are available for altering engine parameters, allowing for performance optimization. Adjustments can be made to fuel economy settings, power output, and other operational aspects, ensuring that each engine runs at its best.

Service Interval Reset Options

Service interval reset features allow for the efficient tracking of maintenance schedules. This function helps in ensuring that engines receive timely inspections and servicing, thus prolonging their lifespan and enhancing reliability.

Real-Time Monitoring and Data Management

Real-time monitoring and data management are essential aspects of effective engine diagnostics. This feature allows for immediate insights into engine performance and operational efficiency.

Monitoring Engine Parameters

The robust monitoring capabilities of NAVISTAR NED 2024 provide users with the ability to track crucial engine parameters in real-time. Key monitored parameters include:

- Engine temperature

- Fuel efficiency

- Oil pressure

- Tachometer readings

This continuous oversight helps in preemptively identifying potential issues before they escalate into significant problems.

View Programming Change Data

In addition to monitoring, users can easily view and track the alterations made to engine programming. This includes:

- Detailed logs of all programming changes

- Historical data comparisons

- Impact assessments of programming adjustments

Such transparency enhances decision-making processes regarding engine management.

Data Save and Print Features

To improve record-keeping and analysis, NAVISTAR NED 2024 includes data save and print functionalities. These features facilitate:

- Archiving essential performance data

- Generating detailed reports for maintenance reviews

- Sharing data with team members for collaborative evaluations

This ability to save and print data reinforces the effectiveness of fleet management practices and long-term planning.

Interface and Usability

The interface and usability of a diagnostic tool are essential for effective operation. NAVISTAR NED 2024 offers a user-friendly experience designed to facilitate quick and efficient diagnostics and programming.

User Interface Overview

NAVISTAR NED 2024 features a modern and intuitive user interface. The layout is straightforward, allowing technicians to navigate through various functionalities with ease. Key components of the interface include:

- Dashboard for quick access to essential tools.

- Color-coded alerts for immediate attention on diagnostic issues.

- Contextual help options to assist users in troubleshooting.

Interfacing with Engines

This tool is compatible with a range of Navistar engines, enabling seamless communication during diagnosis. It supports various protocols, ensuring technicians can connect effortlessly to the engine systems. Users benefit from:

- Direct interface connections with recommended adapters.

- Robust data communication for real-time monitoring.

- Support for different vehicle models to accommodate diverse fleets.

Recommended Hardware and System Requirements

To achieve optimal performance with NAVISTAR NED 2024, specific hardware and system requirements must be met. These include:

- Operating System: Windows 10 (64-bit) or Windows 11 (64-bit).

- Processor: Intel Core 2 Duo (1 GHz) or AMD Athlon X2 or higher.

- RAM: Minimum of 4 GB (64-bit).

- Disk Space: At least 300 MB available.

- Display: Minimum resolution of 1024 x 768 pixels.

Supported Engines and Models

This section highlights the compatibility of NAVISTAR NED 2024 with various engine models, ensuring users have comprehensive support for their fleet needs.

MaxxForce Engines Compatibility

NAVISTAR NED 2024 supports a wide array of MaxxForce engines, ensuring robust diagnostics and programming capabilities. The models covered include:

- MaxxForce 5 (2007-2009)

- MaxxForce 7 (2007-2009; 2010-2012; 2013-)

- MaxxForce DT, 9, 10 (2007-2009; 2010-2012; 2013)

- MaxxForce 11, 13 (2008-2009; 2010-2013)

- MaxxForce 15 (2010-2013)

Coverage for N13 SCR and Newer Models

NAVISTAR NED 2024 extends its coverage to newer models including:

- Models N9 and N10 SCR (2014-)

- N13 SCR (2013-2014, 2015-)

- International A26 SCR (2017-)

Support for International Engine Systems

The tool provides comprehensive diagnostics for a variety of international engines. Some of the supported systems include:

- International engine architectures that adhere to SAE standards.

- Various configurations ensuring compatibility across multiple setups.

Diagnostic Tests and Procedures

Diagnostic tests and procedures are essential for identifying and resolving issues within Navistar engines. These systematic approaches ensure optimal performance and efficiency in fleet operations.

Cylinder Cutout Test Procedures

The cylinder cutout test helps determine the functionality of individual cylinders within the engine. This process involves deactivating one cylinder at a time while monitoring the engine’s performance. Key steps include:

- Preparation of the engine for testing.

- Isolation of the specified cylinder using diagnostic software.

- Evaluation of engine response and identifying any irregularities.

Running Engine Diagnostic Tests

Running engine diagnostic tests provide a comprehensive assessment of the engine’s operational performance. These tests facilitate real-time monitoring of several parameters, including:

- Fuel injection patterns.

- Ignition timing adjustments.

- Performance under various load conditions.

Actuator Tests for Optimal Performance

Actuator tests are crucial for verifying that various engine components are functioning correctly. This process includes testing:

- Throttle actuators for proper response.

- Fuel pump operation to ensure adequate delivery.

- Turbocharger control systems for performance efficiency.

Accurate actuator testing can lead to improved engine performance and longevity.

Customer Feedback and Expert Opinions

Understanding the perspectives of users and experts is crucial to assessing effectiveness and value.

Client Reviews

Feedback from users highlights various aspects of the tool, focusing on ease of use and functionality. Many clients appreciate:

- Intuitive interface, which allows for quick navigation and reduces training time.

- The accuracy of diagnostic results, which helps in prompt issue resolution.

- Comprehensive functionalities that support multiple engine models, catering to diverse fleets.

Users frequently mention that NED 2024 has significantly reduced downtime, enabling more efficient fleet management. Overall satisfaction rates remain high among those who have integrated this software into their maintenance routines.

Expert Analysis on Effectiveness

Experts in the field have conducted extensive evaluations of NED 2024, often noting its advanced capabilities. Key points from their assessments include:

- The software’s robust diagnostic features, which contribute to improved engine performance.

- Real-time monitoring capabilities that enhance proactive maintenance strategies.

- Regular updates ensuring alignment with the latest technological advancements and compliance standards.

Experts agree that NED 2024 sets a new benchmark for engine diagnostics and programming, underlining its essential role in modern fleet service operations.

Acquiring NAVISTAR NED 2024

Obtaining NAVISTAR NED 2024 involves several options, ensuring versatile access and user-friendly installation methods.

Access and Installation Options

Installation of NAVISTAR NED 2024 can be completed through multiple channels. Users can opt for remote installation services or download the software directly.

- Remote Installation: Services such as TeamViewer allow for seamless installation without disrupting workflow.

- Direct Download: Users can download the software from authorized platforms, simplifying the process.

Licensing and Software Updates

Licensing is essential to ensure proper usage of NAVISTAR NED 2024. Users should secure the appropriate license type that fits their operational needs. Frequent software updates enhance the functionality and adapt to evolving technologies.

- License Types: Various licensing options are available depending on the scale of use.

- Software Updates: Regular updates are provided, keeping the tool aligned with the latest engine technologies and diagnostic capabilities.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

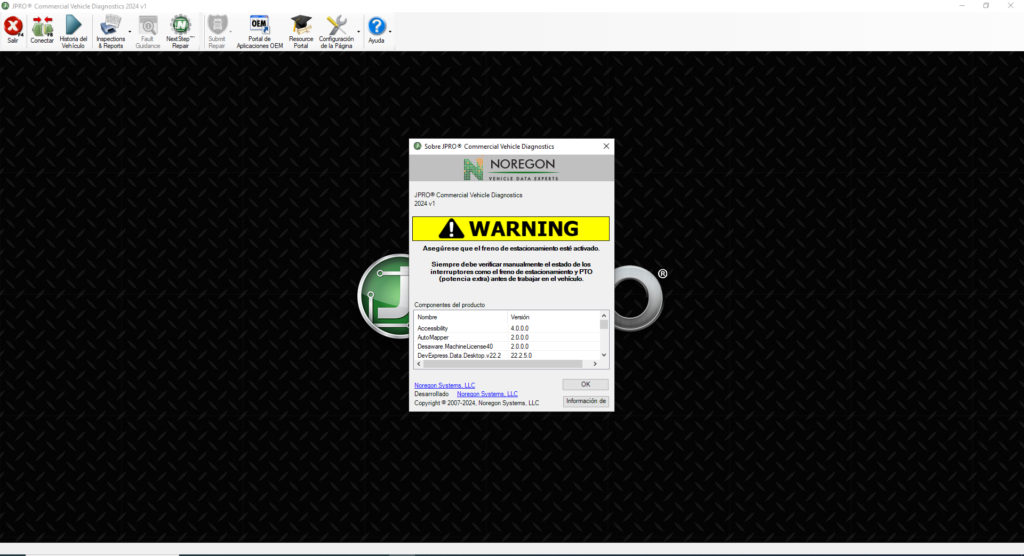

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

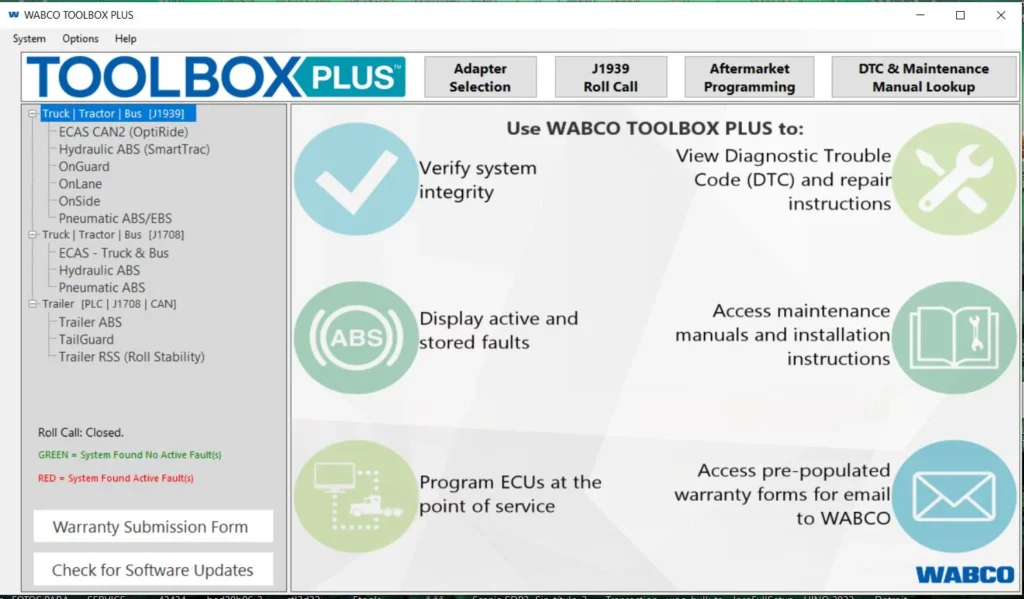

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

Reviews

Clear filtersThere are no reviews yet.