Caterpillar CAT ET 2022A: Essential Diagnostic Tool for Heavy Machinery

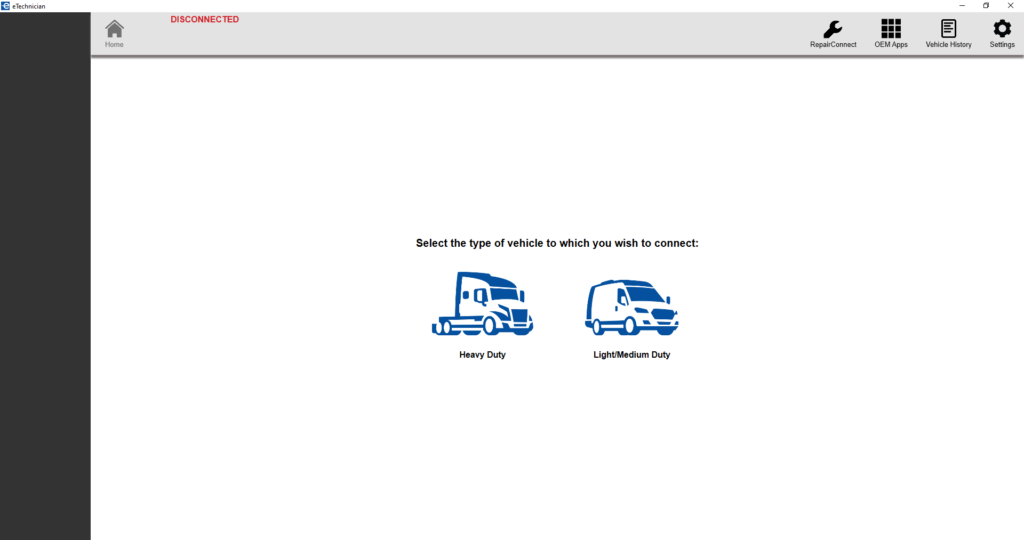

Caterpillar CAT ET 2022A is a diagnostic software designed for heavy machinery. It enables users to interact effectively with electronic control modules, ensuring optimal performance and maintenance of Caterpillar equipment. The software provides tools for diagnosing issues, adjusting parameters, and analyzing data. With its user-friendly interface and robust features, CAT ET 2022A is essential for technicians in various industries, including construction and agriculture.

Overview of Caterpillar CAT ET 2022A

The Caterpillar CAT ET 2022A is a vital tool within the realm of heavy machinery diagnostics, offering a robust framework for troubleshooting and enhancing machinery performance.

Importance in Heavy Machinery Diagnostics

In the world of construction and heavy equipment operation, timely diagnostics can minimize downtime and enhance productivity. The Caterpillar CAT ET 2022A stands out as a critical asset for maintenance professionals. This software empowers technicians to swiftly identify problems and implement coding adjustments to mitigate operational issues.

Its significance lies not only in diagnosing errors but also in its ability to provide insight into the working conditions and performance of various Caterpillar machinery. Accurate diagnostics ensure that machinery operates efficiently, potentially extending the lifespan of the equipment and reducing repair costs.

Key Features

- Diagnostic Tools: The software includes an array of diagnostic tools that facilitate the identification of issues within various machines. These tools provide error codes which help in understanding faults and planning maintenance effectively.

- Reconfiguration Options: Users have the capability to adjust vehicle parameters, tailoring the equipment’s performance to specific operational needs. This flexibility is essential in dynamic work environments where different tasks require varying settings.

- Data Visualization: The CAT ET 2022A allows users to visualize performance data graphically. This feature aids in tracking trends and anomalies by presenting vital information such as temperature and pressure in an easily digestible format.

- Reporting Functions: It enables the generation of detailed reports that document the diagnostic processes and adjustments made to the machinery. Such documentation supports compliance and provides a trail of maintenance activities.

These qualities make the Caterpillar CAT ET 2022A not just a tool for identifying issues, but also a comprehensive solution for promoting overall machinery health and efficiency. Each feature is designed to enhance user experience and ease of operation, ensuring that technicians can work effectively under various conditions.

Main Functions of CAT ET 2022A

The CAT ET 2022A software provides vital functions for diagnosing issues within Caterpillar machinery. It ensures technicians can effectively troubleshoot and make necessary adjustments for optimal performance.

Diagnostic and Reconfiguration Capabilities

One of the core aspects of CAT ET 2022A is its robust diagnostic and reconfiguration capabilities. These features are essential for maintaining machinery performance under various conditions.

Diagnose and Reconfigure Reading

The software allows users to read diagnostic data directly from the equipment’s electronic control modules (ECMs). This reading capability provides technicians with insights into critical variables affecting machinery operations.

Error Codes ECM

Understanding error codes from the ECM is vital for diagnosing problems accurately. CAT ET 2022A enables easy retrieval of these codes, facilitating prompt identification of issues related to the machinery’s performance.

Viewing Events and Data

CAT ET 2022A also excels in its ability to log and display events related to machinery operation. This function plays a crucial role in monitoring the performance and catching potential issues early.

View Events Where Irregularities Occurred and Were Logged

The software records events that indicate irregularities in machinery performance. Users can access logged events to determine when and how issues arose, allowing for timely interventions.

Obtain Data for Analysis

In addition to logging events, CAT ET 2022A provides detailed data for analysis. This data can include operational parameters and performance metrics that help technicians understand the machine’s history and predict future performance trends.

Parameters Adjustment

The ability to modify parameters is another significant function of CAT ET 2022A. This ensures that technicians can customize machinery configurations based on specific operational needs.

Change Vehicle’s Parameters

Technicians can adjust a variety of vehicle parameters, which improves the efficiency and adaptability of Caterpillar equipment in different working environments. This flexibility is crucial for meeting diverse engineering challenges.

Unlock Parameters

In some situations, unlocking specific parameters may be necessary to facilitate advanced configurations. This function empowers technicians to unlock features that alter performance characteristics to suit specific tasks.

Understanding the technical requirements for installation and use is essential to ensure optimal performance of the diagnostic software. Below are the necessary specifications for both software and hardware components.

Technical Requirements for Installation and Use

Supported Operating Systems

Operating System Windows

Caterpillar CAT ET 2022A is designed to operate efficiently on the Windows platform. Compatible versions include Windows 10 and Windows 11. Users must ensure they are running a supported version to avoid compatibility issues.

System Windows Compatibility

It is crucial to note that earlier versions of Windows, particularly Windows 7, are not supported from the 2020B version onwards. Maintaining an up-to-date operating system will facilitate the installation process and enhance software functionality.

Hardware and Connectivity

Control Module ECM

The Electronic Control Module (ECM) forms the backbone of the diagnostic process. A direct connection to the ECM is necessary for the software to function correctly. This module allows for comprehensive diagnostics and parameter adjustments, ensuring that the machinery operates at its best.

Communication Adapter

A compatible communication adapter is required for linking the software with the ECM. Specifically, the Caterpillar Communication Adapter, particularly the CAT Comm Adapter III, is recommended for seamless integration. This adapter facilitates real-time data transfer and diagnostics between the software and the machinery.

Troubleshooting Common Installation Issues

Despite a generally smooth installation process, some users may encounter challenges. Here are common issues and their solutions:

- If the installation stalls or terminates unexpectedly, check if the operating system is up-to-date and all necessary drivers are installed.

- Errors related to missing files often occur due to the absence of components from the Microsoft Visual C++ redistributable package. Ensure this package is installed and updated on the system.

- Users might experience compatibility issues; ensure that CAT ET 2022A is being installed on compatible versions of Windows, particularly Windows 10 or Windows 11.

- In case of network connectivity problems during activation, verify the internet connection and try again. Sometimes restarting the computer may help resolve these issues.

Enhancements in Version 2022A

The 2022A version introduces significant upgrades that enhance usability and diagnostic capabilities. These enhancements have been thoughtfully designed to meet the evolving needs of technicians and operators in the field.

Improved Interface

The interface of the CAT ET 2022A has undergone a complete redesign aimed at streamlining user interaction. This upgrade provides a more intuitive layout, making navigation simpler and faster for users. The modernized interface includes:

- Clear visual indicators that guide users through the diagnostic process.

- A customizable dashboard that allows technicians to prioritize essential tools and data for quicker access.

- Enhanced graphics that improve the clarity of data presentation, enabling easier interpretation of performance metrics.

New System Features

In addition to the improved interface, CAT ET 2022A incorporates several new features that significantly expand its diagnostic capabilities.

New File Comparison System

This innovative feature allows users to compare different ECM files side-by-side. Technicians can easily identify discrepancies between the current and replacement files, which aids in troubleshooting and optimizing machine performance. This systematic approach to file comparison enhances accuracy in diagnostics and minimizes downtime.

Updates in User Interface

The updates extend beyond aesthetic improvements. Additional functionalities integrated within the user interface include:

- Enhanced filtering options for event logs, allowing users to quickly pinpoint specific anomalies.

- Integration of a help section that provides contextual information on various features, ensuring users can access assistance when needed.

- Support for high-resolution displays, which makes the use of the software more effective on modern devices.

These enhancements collectively make the CAT ET 2022A a more powerful tool for managing and diagnosing Caterpillar machinery, driving efficiency and reliability in heavy machinery operations.

User Experiences and Feedback

The feedback from users plays a crucial role in understanding the effectiveness and usability of any diagnostic tool. Insights shared by professionals who have engaged with the software shed light on its practicality and areas for improvement.

User Testimonials

A number of users have provided affirmative feedback regarding the functionality and reliability of the debugging features offered by the software. For instance, one technician remarked, “Using CAT ET 2022A has significantly streamlined my diagnostic process. The error codes are easy to navigate, and I’ve noticed improved response times for setup.” Such testimonials highlight how the user-friendly interface has been beneficial in real-life applications.

Another user, a maintenance manager from a construction firm, stated, “The ability to change vehicle parameters on the fly has enabled our team to adapt equipment settings based on site conditions. This adaptability has greatly enhanced productivity.” This adaptability emphasizes the flexibility of the software in various operational circumstances.

Moreover, many users appreciate the comprehensive reporting capabilities. A fleet supervisor shared, “Generating detailed reports saves us time and ensures we have a reliable record for future reference.” This aspect is particularly important for maintaining compliance and tracking equipment performance over time.

Common Praise and Criticism

Positive feedback generally centers around several main features:

- Ease of installation and activation

- High accuracy in diagnosing problems

- Comprehensive functionality for parameter adjustments

Users frequently express satisfaction with how accessible the installation process is, allowing technicians to get to work quickly. The accuracy and speed of problem diagnosis are also frequently lauded, as they reduce downtime and enhance operational efficiency. Furthermore, the ability to adjust vehicle parameters is seen as a significant boon for many technicians.

However, some common critique points have emerged as well. For example, certain users have reported challenges with software compatibility when using older operating systems. Others have mentioned a steep learning curve for less experienced technicians who may find the interface complex at first glance.

Despite these criticisms, the overall sentiment remains positive. Users are willing to overlook minor hurdles due to the substantial benefits the software provides in diagnosing and managing Caterpillar machinery.

Integration with Other Caterpillar Products

The integration of Caterpillar CAT ET 2022A with other Caterpillar products enhances the functionality and efficiency of heavy machinery operations. This synergy allows operators to maximize productivity and ensure optimal machine performance through coordinated technology and resources.

Related Equipment and Tools

Caterpillar offers a comprehensive range of equipment and tools that complement the capabilities of CAT ET 2022A. These products work together to provide seamless diagnostics and maintenance, streamlining the workflow for operators and technicians. Key related tools include:

- Caterpillar Communication Adapter III: This adapter is essential for connecting CAT ET to the ECM of various machinery. Its compatibility ensures accurate communication and data transfer between the diagnostic software and the equipment.

- Diagnostic Workstations: Caterpillar provides dedicated workstations equipped with specialized software and tools designed for in-depth analysis and maintenance. These workstations often feature upgraded hardware to support complex diagnostics.

- Service Toolkits: Robust toolkits that include essential instruments for electrical troubleshooting and mechanical maintenance complement the software, enabling techs to address issues quickly and efficiently.

Applications Across Different Industries

Caterpillar CAT ET 2022A serves critical roles across multiple industries, enhancing the efficiency and reliability of heavy machinery. Its adaptability makes it suitable for various applications, ensuring optimal performance in diverse operational environments.

Construction

In the construction sector, heavy machinery such as excavators, bulldozers, and graders are pivotal. The ability to quickly diagnose issues and make adjustments ensures minimal downtime, which is essential for meeting project deadlines. Key applications include:

- Regular maintenance checks to prevent equipment failures.

- Adjustment of machine parameters to fit specific job requirements, optimizing performance.

- Data analysis for monitoring equipment health over time, aiding in proactive maintenance strategies.

Agriculture

The agricultural industry relies heavily on machinery for tasks ranging from planting to harvesting. Effective management of these machines can significantly enhance productivity. Applications in agriculture include:

- Supervision of tractor performance, ensuring optimal fuel efficiency during operations.

- Real-time diagnostics to tackle issues with harvesting equipment, ensuring timely harvests.

- Modification of machinery settings to adapt to various cropping conditions.

Mining

Mining operations involve some of the most demanding environments for equipment. Ensuring machinery is operating at peak performance is critical for safety and productivity. In this field, key applications consist of:

- Monitoring drill and haul truck performance to maximize extraction efficiency.

- Detailed diagnostic reporting to prevent unexpected breakdowns.

- Configuring machinery for various mineral extraction techniques, enhancing versatility.

Energy Systems

In energy production, particularly in oil and gas, as well as renewable energy sectors, reliability is paramount. The software’s diagnostic capabilities play an important role in maintaining equipment efficiency. Applications for energy systems include:

- Continuous monitoring of generators and turbines to ensure they operate within safe parameters.

- Adjusting performance settings for machinery used in different energy production scenarios.

- Utilizing data analytics to inform decisions on maintenance schedules and operational adjustments.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BENDIX

BENDIX

EATON

EATON

Cumminz

Cumminz

All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR