Volvo Tech Tool Diagnostic Software 2 8 150: Essential Tool for Volvo Vehicle Maintenance

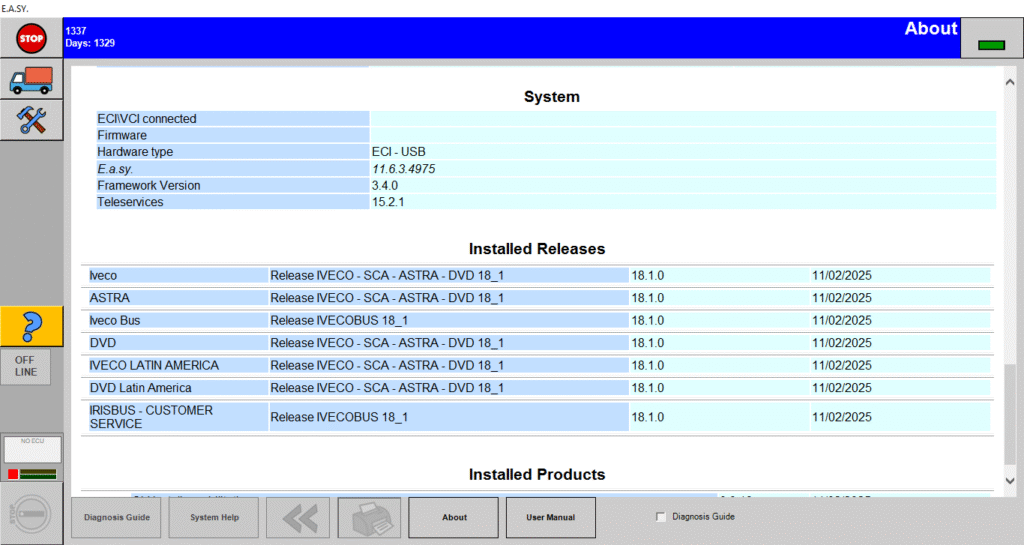

Volvo Tech Tool Diagnostic Software 2.8.150 is a crucial tool for diagnosing and maintaining Volvo vehicles. It offers a range of functions that help technicians perform effective repairs and adjustments. This software is compatible with various Volvo models and provides features such as fault code identification and component calibration. Its user-friendly interface simplifies the diagnostic process for both experienced and new technicians.

Table of Contents

ToggleOverview of Volvo Tech Tool 2.8.150

The Volvo Tech Tool 2.8.150 is a powerful diagnostic tool tailored for maintaining and repairing Volvo vehicles. It equips technicians with the necessary functions to ensure optimal performance and reliability.

Key Features

- Comprehensive fault code identification

- Advanced calibration options for various vehicle components

- User-friendly interface facilitating quick navigation

- Regular updates that enhance functionality and compatibility

System Compatibility

This software supports various systems, making it a versatile solution for multiple vehicle types.

Compatible Vehicles

- Volvo trucks, including models with older electrical systems

- Volvo buses, accommodating both conventional and multiplexed systems

- Construction equipment from Volvo, ensuring broad applicability

Hardware Requirements

To run smoothly, certain hardware specifications are necessary. A dual-core processor, ideally i3 or better, along with a minimum of 4GB of RAM, is recommended.

Installation Process

The installation of the software requires careful steps to achieve successful completion.

Pre-Installation Steps

- Disable any antivirus software to avoid installation interruptions

- Ensure the system meets the specified hardware requirements

Installation Methods

- Direct installation on an SSD for improved performance

- Remote installation options are available, potentially at an extra cost

Functional Capabilities

The functional capabilities of this diagnostic software are extensive, allowing for effective vehicle maintenance and troubleshooting.

Diagnostic Functions

This software provides a range of diagnostic functions tailored for Volvo vehicles.

Fault Code Identification

It enables technicians to identify fault codes efficiently. By connecting to the vehicle’s onboard computer, it retrieves error codes that pinpoint specific issues within various systems, streamlining the diagnostic process.

Performance Testing

Performance testing is an integral feature. This function assesses crucial vehicle parameters, helping to ensure that all systems are operating optimally. It highlights potential performance bottlenecks, allowing for timely interventions.

Calibration and Programming

Calibration and programming functionalities further enhance vehicle management.

Engine Calibration

The software facilitates precise engine calibration, ensuring that the engine operates in accordance with factory specifications. This calibration is vital for maximizing performance and fuel efficiency.

Parameter Adjustments

Users can make necessary parameter adjustments to adapt the vehicle’s functions to specific needs. This flexibility allows for customization based on operating conditions or user preferences.

Advanced Tools

Advanced tools are available for more in-depth diagnostics.

History View

A history view tool keeps a record of previous diagnostics performed. This feature helps in tracking recurring issues and provides a comprehensive overview of vehicle performance over time.

Specialized Testing

Specialized testing is offered to conduct specific assessments on components. This allows technicians to verify the operational status of critical systems, enhancing overall reliability.

User Experience

The user experience with the Volvo Tech Tool Diagnostic Software 2.8.150 has been optimized for efficiency and ease of use. Technicians and fleet managers alike benefit from its accessible design and functionality.

Interface Design

The interface is designed to be intuitive, featuring a clean layout that allows for quick navigation through various diagnostic functions. Key elements include:

- Clear menu options for accessing different tools and features

- Visual indicators to show system status and alerts

- Customizable settings to tailor the experience to individual user preferences

Usage Scenarios

The software offers versatile applications for different user roles, enhancing overall productivity in the workplace.

For Workshop Technicians

Workshop technicians appreciate the streamlined process for diagnosing vehicle issues. The software allows them to:

- Quickly identify fault codes

- Perform calibrations and adjustments on various components

- Access historical data for better troubleshooting

For Fleet Managers

Fleet managers find the software advantageous for managing multiple vehicles efficiently. Its features support:

- Real-time monitoring of vehicle performance

- Generation of comprehensive reports for fleet maintenance

- Enhanced scheduling for regular diagnostics and updates

Support and updates are crucial aspects of maintaining the functionality and efficiency of the diagnostic software. Regular assistance and timely updates help users maximize the tool’s capabilities.

Support and Updates

Customer Support Services

Volvo provides comprehensive customer support services for PTT 2.8.150 users. This support includes:

- Online knowledge base with troubleshooting tips and best practices.

- Access to user forums for community help and shared experiences.

- Direct support lines for urgent queries related to software functionalities.

These services ensure that technicians receive the necessary guidance to resolve any issues promptly.

Software Updates

Regular software updates are essential for enhancing performance and security. Volvo often releases updates to improve existing features and provide new functionalities.

Frequency and Improvements

Updates are typically released on a scheduled basis, ensuring users benefit from the latest enhancements. Improvements often focus on:

- Bug fixes that enhance stability and performance.

- New diagnostic features that expand capabilities.

- Increased compatibility with newer vehicle models.

Installation of Updates

The installation of updates can be done manually or automatically, depending on user preferences. The process involves:

- Downloading the latest version from the official site.

- Following straightforward prompts to install.

- Restarting the software to apply changes.

Proper installation ensures that users can utilize the newest enhancements immediately.

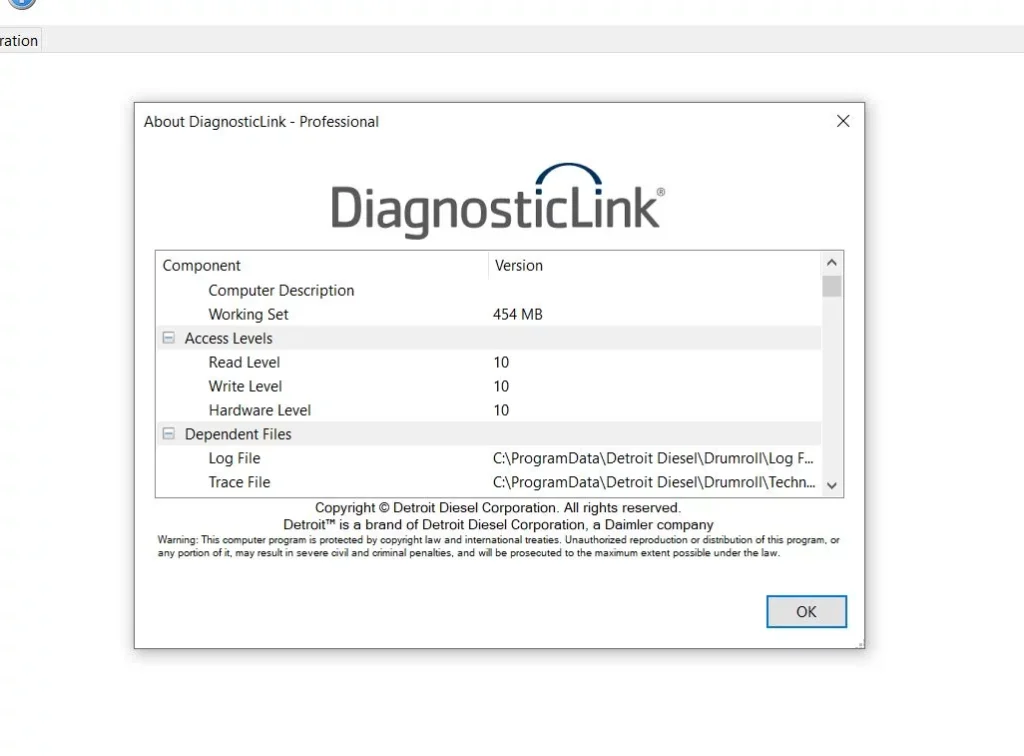

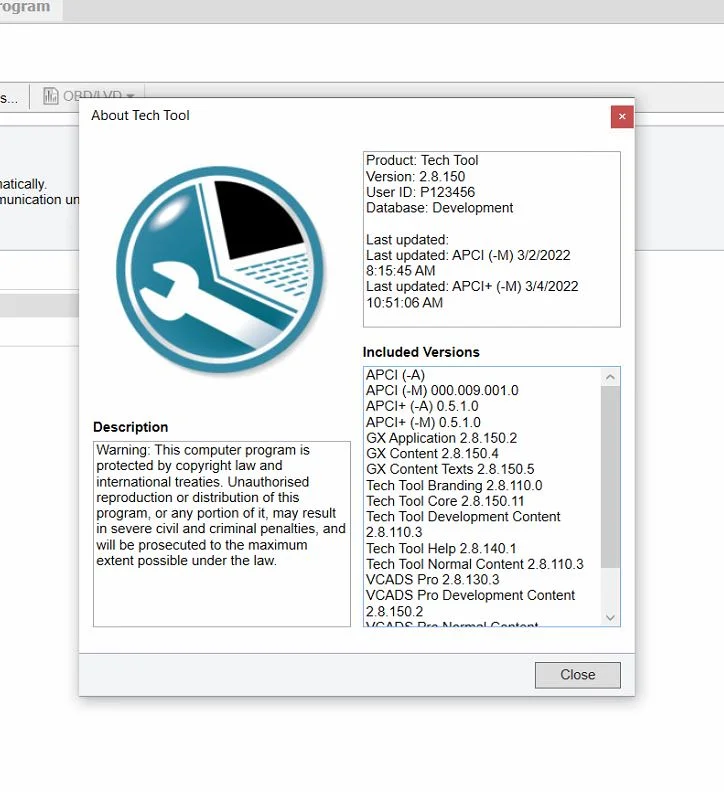

Comparing Alternatives

When evaluating diagnostic software, it’s important to consider available alternatives that cater to similar needs. Different tools may offer varying functionalities, which can impact overall efficiency and effectiveness in vehicle maintenance.

Other Diagnostic Tools

Various diagnostic tools exist in the market, each designed to cater to specific brands or vehicle types. Some popular alternatives include:

- VXDIAG VCX Nano GDS2

- JPRO Professional Diagnostic Tool

- Autel MaxiSys Elite

These tools generally provide features such as basic fault code reading, live data monitoring, and limited programming capabilities. However, their effectiveness may vary depending on vehicle make and model.

Advantages of Volvo Tech Tool

The Volvo Tech Tool offers several advantages over these alternatives, making it a preferred choice for many technicians working with Volvo vehicles.

Specialized for Volvo Vehicles

This tool is explicitly designed for Volvo and Mack vehicles, ensuring compatibility with a wide range of models. Its specialized features streamline diagnostics and repair processes effectively.

Cost-Benefit Analysis

While the initial investment in Volvo Tech Tool might be higher compared to some alternatives, its tailored functionality can lead to cost savings in the long run. Quick diagnostics and accurate fault identification reduce time spent on repairs, enhancing workshop productivity.

Common User Questions

Various questions arise among users regarding the functionalities and troubleshooting of the software. Here are some common inquiries.

Troubleshooting Installation Issues

Installation problems can stem from a variety of factors. Users often face:

- Conflicts with antivirus software, which may block installation files.

- Insufficient system requirements leading to installation failures.

- Inappropriate settings in Windows that might prevent the software from running optimally.

Maximizing Diagnostic Accuracy

To ensure precise diagnostics, users should consider the following:

- Regularly update the software to incorporate the latest protocols and fixes.

- Conduct comprehensive system checks on vehicles to gather accurate readings.

- Verify all connections and compatibility with vehicle models before proceeding with diagnostics.

Ensuring Hardware Compatibility

Hardware compatibility is crucial for seamless operation. Key considerations include:

- Utilizing a recommended PC configuration, including compatible processor and RAM specifications.

- Verifying that the system has the latest drivers installed for peripherals and hardware components.

- Checking the brand and model of the computer, as some do not fully support the software’s requirements.

Customer Reviews and Feedback

Customer reviews play a crucial role in assessing the effectiveness and usability of software tools like the Volvo Tech Tool 2.8.150. Feedback from users highlights various aspects of their experiences.

General User Opinions

The general sentiment among users of the Volvo Tech Tool 2.8.150 is largely positive. Technicians appreciate its comprehensive diagnostic capabilities, which enable efficient troubleshooting. Many express satisfaction with the software’s performance and its ability to connect seamlessly with various Volvo models.

Review Highlights

-

Positive Feedback

Users frequently commend the following features:

- User-friendly interface that simplifies navigation.

- Effective fault code identification that saves time during repairs.

- Regular software updates that enhance functionality.

-

Areas for Improvement

Some users have identified areas where improvements could be made:

- Compatibility issues with certain hardware brands.

- A steeper learning curve for new technicians.

- Higher costs associated with licensing and updates.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![DOOSAN E-POWERPACK DIAGNOSTIC PROGRAM v00.12 [2023.08]](https://ecmtrucks.com/wp-content/uploads/2024/08/33-150x150.png)