Bobcat Service Library 2019: Essential Maintenance Resources for Your Equipment

The Bobcat Service Library 2019 is a comprehensive resource designed for owners and operators of Bobcat machinery. It includes essential manuals, guides, and diagnostic tools to support effective maintenance and repair. This library plays a crucial role in ensuring optimal performance of equipment. Users can access valuable information on service procedures, parts ordering, and troubleshooting common issues.

Table of Contents

ToggleUnderstanding the Bobcat Service Library 2019

This section provides an essential overview of the Bobcat Service Library 2019, focusing on its contents, key features, and methods of access.

What is Included in the Library?

The library offers a comprehensive collection of resources essential for maintaining Bobcat equipment. These resources include:

- Service Manuals

- Parts Catalogs

- Diagnostic Tools and Guides

Each category is designed to support equipment operators in efficient maintenance, troubleshooting, and maximization of machinery performance.

Key Features and Benefits

The Bobcat Service Library boasts several features that enhance usability and provide significant advantages:

- Detailed Instructions: Manuals and guides provide step-by-step procedures for various maintenance and repair tasks.

- Easy Parts Ordering: The catalog simplifies the identification and ordering of replacement parts.

- Diagnostic Assistance: Diagnostic tools assist in identifying and resolving common operational issues.

These features contribute to improved efficiency and reduced equipment downtime, leading to enhanced productivity in operations.

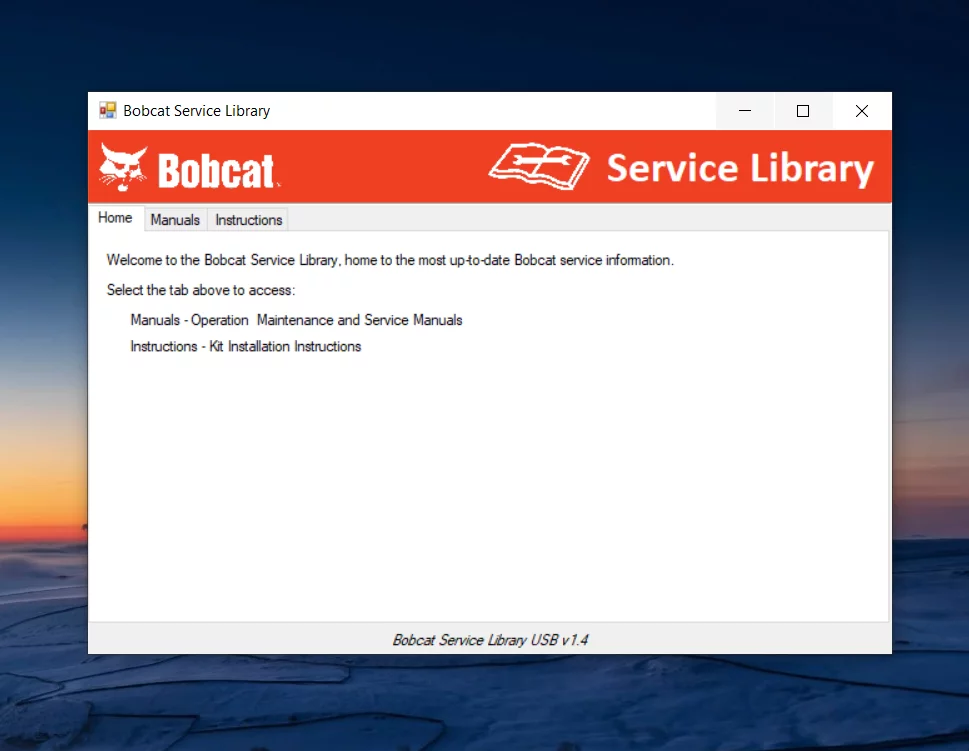

How to Access the Library

Accessing the Bobcat Service Library is a straightforward process:

- Visit the official website of Bobcat.

- Navigate to the Service Library section.

- Utilize the search function to find specific manuals or guides.

- Download materials in various formats for offline or online use.

This convenient access ensures that users can quickly locate the resources they need for effective equipment management.

Detailed Overview of Service Manuals

Service manuals are vital resources for maintaining and repairing Bobcat equipment. They provide comprehensive insights tailored for various models, ensuring optimal functionality and safety during operations.

Loaders and Skid Steer Loaders

Maintenance Procedures

Maintenance procedures for loaders and skid steer loaders encompass regular inspections and routine service tasks. It is crucial to check fluid levels, inspect hydraulic systems, and replace filters as advised by the manufacturer.

Repair Techniques

Repair techniques include step-by-step guidelines for addressing common issues such as hydraulic leaks, engine problems, and electrical failures. Users can find easy-to-follow instructions to streamline the repair process and enhance machine lifespan.

Compact Excavators and Mini Excavators

Operation Guidelines

Operation guidelines provide essential information on how to efficiently operate compact and mini excavators. They cover aspects like digging techniques, attachment use, and optimal machine settings for various tasks.

Safety Measures

Safety measures highlight the importance of using personal protective equipment and following best practices while operating excavators. These guidelines aim to reduce the risk of accidents and ensure the safety of all personnel on site.

Utility and Compact Tractors

Routine Maintenance Tips

Routine maintenance tips for utility and compact tractors focus on tasks such as checking tire pressure, greasing moving parts, and monitoring engine performance. Regular maintenance greatly contributes to reliable and efficient operation.

Troubleshooting Common Issues

Troubleshooting common issues involves identifying problems such as starting difficulties or unusual noises during operation. The manuals provide diagnostic steps to facilitate swift resolution and minimize downtime.

Parts Catalogs and Their Importance

Parts catalogs are vital tools for maintaining and repairing Bobcat equipment. They ensure that owners and technicians can quickly identify and order the precise components needed for efficient operation.

Identifying Bobcat Parts

One of the primary functions of parts catalogs is to provide detailed information about all Bobcat parts. This includes:

- Part Numbers: Unique identifiers for each component, making it easy to locate specific items.

- Specifications: Technical details that define the compatibility and functionality of the parts.

- Application Guides: Information on which machinery or models utilize specific parts.

Simplifying Parts Ordering

The process of ordering parts is streamlined through the catalogs, which offer several advantages:

- Direct Ordering: Users can order parts directly from the catalog without intermediary steps.

- Efficient Processes: Reduce delays by ensuring that all necessary information is readily available.

- Minimized Errors: Clear part descriptions help prevent ordering mistakes.

Using Detailed Images and Descriptions

Visual aids significantly enhance the usability of parts catalogs:

- Illustrations: Clear images of each part help users confirm they are selecting the right component.

- Comprehensive Descriptions: Detailed explanations provide insights into the function and features of parts.

- Ordering Assistance: Guidance on how to order each part assists in seamless procurement.

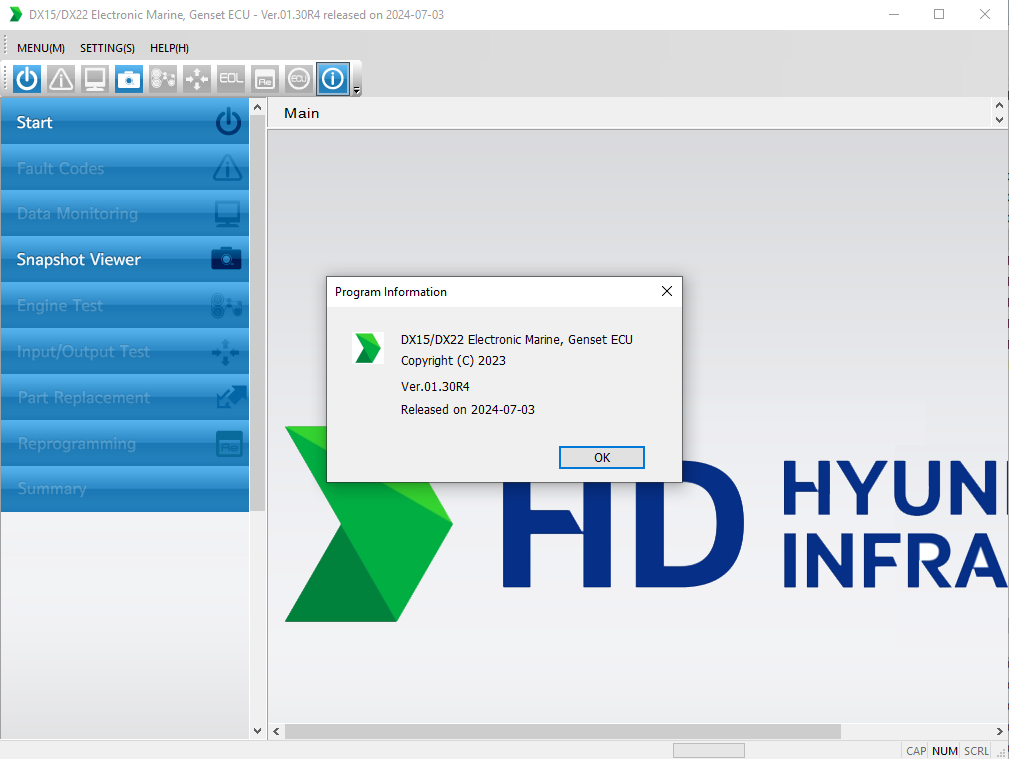

Diagnostic Tools and Software

Effective diagnostics are crucial for maintaining the performance and reliability of Bobcat equipment. Several tools and software options can be used to identify issues and enhance overall equipment efficiency.

Common Diagnostic Challenges

Owners and operators often face various challenges when diagnosing machinery problems. Some of the most prevalent issues include:

- Difficulty in pinpointing the exact source of mechanical failures.

- Time-consuming manual troubleshooting methods.

- Inconsistent diagnostic results due to the complexity of modern equipment.

Utilizing Diagnostic Software

Implementing specialized diagnostic software is essential for a more streamlined approach to maintenance. This software offers several advantages:

- Automated diagnostic checks that reduce the time required for troubleshooting.

- Access to real-time data that helps in making informed decisions regarding repairs.

- User-friendly interfaces that facilitate quick operation and understanding.

Enhancing Equipment Efficiency

Integrating diagnostic tools and software not only assists in problem resolution but also plays a significant role in boosting overall equipment efficiency. Key factors include:

- Regular updates to the software ensure compatibility with the latest machinery features.

- Predictive maintenance capabilities that help prevent future issues.

- Improved resource allocation through better diagnostics, reducing downtime.

Maintenance and Repair Resources

Effective maintenance and repair resources are crucial for maximizing the performance and longevity of Bobcat equipment. These resources encompass preventive maintenance schedules, cost-effective repair strategies, and methods for extending equipment life.

Preventive Maintenance Schedules

Preventive maintenance is essential to keep Bobcat machinery operating efficiently. Regular schedules help in identifying potential issues before they escalate into significant repairs. Key elements of these schedules include:

- Routine inspections of all machinery components

- Timely oil changes and fluid checks

- Scheduled replacement of wear parts

- Documentation of service history for tracking maintenance

Cost-Effective Repair Strategies

Implementing cost-effective repair strategies reduces downtime and minimizes expenses. Effective approaches include:

- Conducting thorough diagnostics to pinpoint issues accurately

- Utilizing the parts catalog for original equipment manufacturer (OEM) components

- Encouraging in-house maintenance training for operators and technicians

- Establishing partnerships with local service providers for specialized repairs

Extending Equipment Life

To maximize the lifespan of Bobcat machines, operators should consider the following practices:

- Regular lubrication of moving parts to prevent wear and tear

- Implementing appropriate operating techniques to reduce strain on equipment

- Monitoring equipment performance metrics to identify areas for improvement

- Conducting seasonal maintenance checks to prepare for changing conditions

Innovations and Technological Advancements

The continuous advancements in Bobcat equipment reflect a commitment to enhance user experience and operational efficiency. By integrating cutting-edge technology, these innovations provide significant benefits to operators in various industries.

Latest Features in Bobcat Equipment

Bobcat’s newer models come equipped with features that improve overall functionality and usability. Key innovations include:

- Improved hydraulic systems that enhance lifting capabilities and response times.

- Ergonomically designed cabins that provide greater comfort and visibility for operators.

- Advanced diagnostic tools that allow for real-time performance monitoring.

Energy Efficiency Improvements

Energy consumption is a critical factor in operational costs. Bobcat has made significant strides in increasing energy efficiency across its range of equipment:

- Utilization of fuel-efficient engines that maximize power and reduce emissions.

- Adoption of lightweight materials that enhance performance without sacrificing durability.

- Smart technology that optimizes machine functions for minimal energy usage during operations.

Advanced Control Systems

Modern Bobcat equipment incorporates sophisticated control systems that offer greater precision and ease of use:

- Intuitive interfaces that simplify operation, making it easier for operators to manage complex tasks.

- Programmable settings that allow customization based on specific job requirements.

- Enhanced safety features such as automatic shut-off systems to prevent accidents.

Frequently Asked Questions about Bobcat Service Library

The following section addresses common inquiries regarding the Bobcat Service Library. These frequently asked questions provide clarity on user concerns, maximizing resource use, and available support.

Common User Concerns

Users often have similar questions regarding functionality and accessibility. Here are some key concerns:

- What types of equipment are covered in the library?

- Are the service manuals up-to-date?

- Can I access the library without an internet connection?

How to Maximize the Use of the Library

To make the most of the resources available in the Bobcat Service Library, users should consider the following tips:

- Familiarize yourself with the layout and organization of manuals.

- Use search functionality to quickly locate specific topics.

- Regularly check for updates or new resources available online.

Additional Resources and Support

For users seeking further assistance or information, the following resources are beneficial:

- Official Bobcat website for technical updates and new releases.

- Online forums and community groups for shared experiences and solutions.

- Customer support contacts for direct queries regarding specific issues.

AGCO

AGCO ALLISON

ALLISON BENDIX

BENDIX BOBCAT

BOBCAT CAT

CAT CLAAS

CLAAS CNH

CNH DAF

DAF DETROIT

DETROIT EATON

EATON FREIGHTLINER

FREIGHTLINER HINO

HINO HITACHI

HITACHI ISUZU

ISUZU JCB

JCB JOHN DEERE

JOHN DEERE JPROZZ

JPROZZ MAGIC TUNER

MAGIC TUNER MAN

MAN Navistar

Navistar PACCAR

PACCAR PERKINS

PERKINS PF DIAGNOSE

PF DIAGNOSE PSI POWERLINK

PSI POWERLINK RENAULT

RENAULT SCANIA

SCANIA THERMO KING

THERMO KING UD NISSAN

UD NISSAN VOLVO

VOLVO WABCO

WABCO ZF TESTMAN

ZF TESTMAN

BELL

BELL BENDIX

BENDIX BOBCAT

BOBCAT CARRIE

CARRIE DAF

DAF DETROIT

DETROIT EATON

EATON FUSO

FUSO MACK

MACK

Cumminz

Cumminz ISB4.5 CM2150

ISB4.5 CM2150 All Engines (2017 Emissions)

All Engines (2017 Emissions) PACCAR

PACCAR

![The Doosan Diagnostic Tool DX22 Generator Engine 00.13 [2023.06] is essential for maintaining and diagnosing Doosan generators. It provides a comprehensive solution designed for efficiency and performance in heavy equipment. This tool enhances operational reliability by offering real-time monitoring and advanced diagnostic features. Its user-friendly interface simplifies troubleshooting, making it a valuable asset for technicians and maintenance teams in various industries.](https://ecmtrucks.com/wp-content/uploads/2024/08/3.png)